Digital Pressure Meter: The Essential Checks for Industrial & Medical Gas Systems and The Absolute Role of Pressure Meter Calibration

In numerous industries—from pharmaceutical and chemical manufacturing to HVAC systems and healthcare—pressure is one of the most critical physical parameters requiring precise control and measurement. The slightest deviation in pressure measurement can lead to severe consequences: ranging from product defects, energy waste, equipment damage, to significant safety risks. The Digital Pressure Meter is an indispensable instrument, offering quick, accurate, and reliable measurement capabilities. This device helps engineers, maintenance technicians, and quality professionals monitor, diagnose, and optimize system performance. However, the reliability of every pressure measurement hinges on the accuracy of the internal sensor. Therefore, routine Pressure Meter Calibration is a mandatory requirement to maintain data integrity and ensure operational safety and efficiency.

What is a Pressure Meter?

A Pressure Meter, especially the digital version (Digital Pressure Meter), is a measuring instrument used to determine the force applied perpendicular to a unit of area (known as pressure) in a liquid or gas.

- Operating Principle: The device consists of a pressure sensor that works by converting physical pressure into an electrical signal. This signal is then processed by the digital unit and converted into the pressure value displayed on the screen.

- Types of Pressure Measured:

- Absolute Pressure: Measures pressure relative to a perfect vacuum.

- Gauge Pressure: Measures pressure relative to ambient atmospheric pressure.

- Differential Pressure: Measures the difference between two pressure points.

- Measurement Units: The device can display results in various units, most commonly Pascals (Pa), psi (pounds per square inch), bar, atm (atmosphere), mmHg (millimeters of mercury), etc.

- Role: The Digital Pressure Meter serves as a link between the physical world and human control, turning an invisible physical quantity into a tangible number, thus enabling effective monitoring and adjustment of systems.

1. The Critical Importance of Pressure in Various Industries

HVAC & Cleanrooms

Measures differential pressure across HEPA filters. Verifies positive/negative room pressure.

Medical & Pharma

Checks ventilators and anesthesia machines. Ensures patient safety and GMP compliance.

Manufacturing & Hydraulics

Controls pneumatic/hydraulic systems. Conducts leak testing in sealed systems and vessels.

Pressure is a key variable that influences many physical and chemical processes.

1.1. Applications in HVAC Systems (Heating, Ventilation, Air Conditioning)

- Differential Pressure Measurement: Essential for determining the filter efficiency of HEPA filters in cleanrooms or evaluating airflow dynamics in ductwork.

- System Diagnostics: Troubleshooting faults in air conditioning or ventilation systems by measuring refrigerant gas pressure or static pressure.

1.2. Medical and Cleanroom Environments

- Cleanroom Pressure Verification: Ensuring required positive or negative pressure is maintained to prevent contamination or contain airborne pathogens.

- Medical Equipment Testing: Measuring pressure in critical devices such as ventilators and anesthesia machines to ensure accurate and safe patient operation.

1.3. Manufacturing and Testing Industries

- Process Control: Monitoring pressure in pipelines, vessels, and hydraulic/pneumatic systems to ensure stable and safe production processes.

- Leak Testing: Identifying leaks in sealed systems by measuring the pressure decay over time.

2. Advantages of the Digital Pressure Meter

Superior Accuracy and Resolution

Offers much higher precision than mechanical gauges. Digital display minimizes human reading error.

Data Logging and Analysis

Capability to record pressure data over time for trend analysis and intermittent fault diagnosis.

Compared to mechanical pressure gauges, digital meters offer several significant advantages.

2.1. High Accuracy and Superior Resolution

- Reliable Results: Digital pressure sensors offer significantly higher accuracy, with the capability to measure even minor pressure changes.

- Digital Display: Facilitates easy reading, reducing human error associated with misinterpreting analog scales.

2.2. Data Logging and Analysis Capabilities

- Data Logging: Many devices have the ability to record pressure data over time, which helps track trends, analyze performance, and diagnose intermittent issues.

- Min/Max/Hold Functions: Assists in capturing peak high or low pressure values or holding the current reading.

3. The Absolute Role of Pressure Meter Calibration

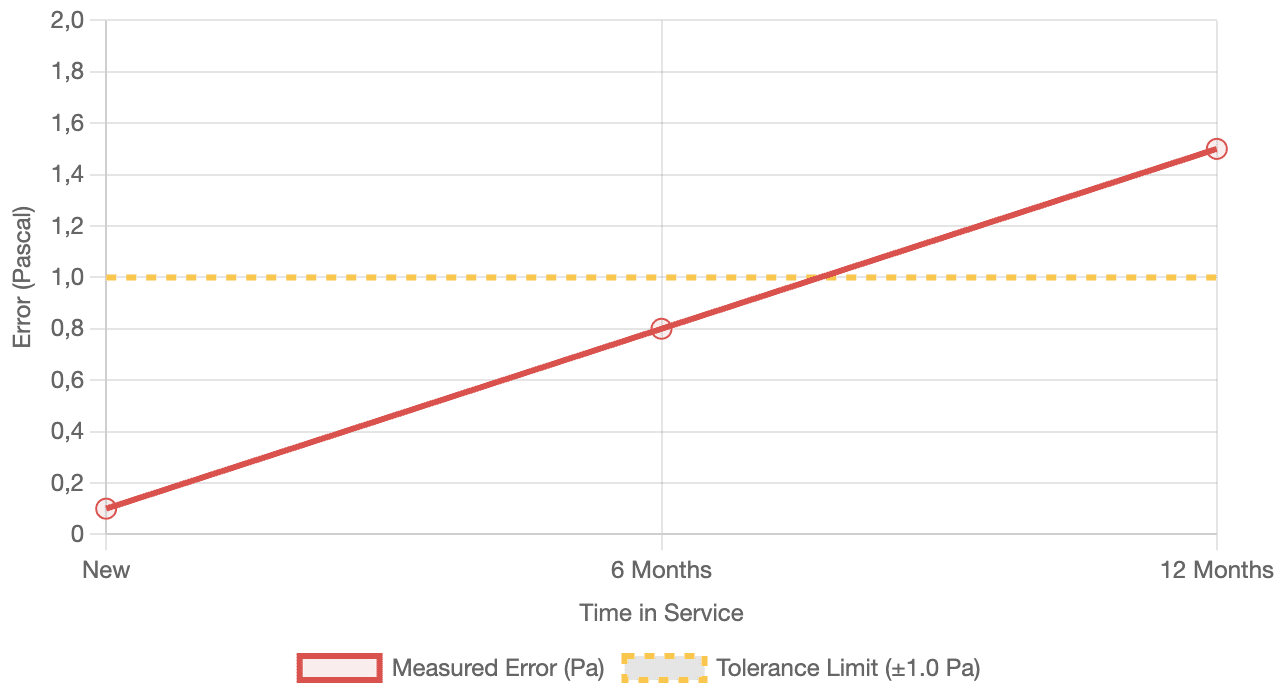

An uncalibrated sensor will drift over time, providing erroneous data. This can lead to system over-pressurization or under-pressurization.

Sensor Drift Over 12 Months

The measured value gradually drifts outside the acceptable tolerance threshold.

Impact on Cleanroom

A faulty device reads 8 Pa (FAIL), while the actual pressure is 11 Pa (PASS), resulting in unnecessary production shutdown.

Any pressure measurement must be trustworthy, and this can only be achieved through calibration.

3.1. Ensuring Accuracy and Operational Safety

- Sensor Verification: Calibration checks that the device’s pressure sensor responds correctly across various pressure levels. If the sensor experiences drift, the meter will provide inaccurate readings.

- Preventing Failures: An inaccurate pressure meter can lead to systems being operated under- or over-pressurized, causing equipment damage, product defects, or even dangerous accidents. Calibration ensures you can rely on the displayed metrics.

3.2. Compliance with International and Industry Standards

- Traceability Certificate: Routine calibration provides a Traceability Certificate, which is indispensable evidence to demonstrate compliance with quality standards (such as ISO 9001, ISO 17025) and industry regulations (e.g., pharmaceutical, aerospace).

- Data Consistency: Calibration ensures that measurement results from all pressure meters within the same facility are consistent and comparable.

3.3. Calibration Procedure for Core Parameters

This process ensures accurate measurement across full range, both during increasing and decreasing pressure.

Pressure Meter Calibration involves comparing the device under calibration with a highly accurate Reference Pressure Standard. The critical checks include:

- Linearity: Verifying the device measures accurately across its full range.

- Repeatability: Ensuring the device yields the same result when measuring the same pressure multiple times.

- Hysteresis: Checking for the difference in reading when pressure is increasing versus decreasing.

- Zero Point: Verifying the device reads zero when no pressure is applied.

Conclusion

The Digital Pressure Meter is an essential diagnostic and control tool in many industrial and scientific settings. However, its value is only truly realized when the collected data is accurate. Therefore, Pressure Meter Calibration is not merely a maintenance procedure, but a strategic commitment to operational safety, product quality, and adherence to strict regulations. The investment in routine calibration is the guarantee for the long-term reliability and efficiency of all pressure-dependent systems.