Specialized Capacitance Meter: Assessing Electronic Component Health – The Absolute Need for Calibration

In electronics, telecom, and electrical engineering, Capacitance is a basic but vital factor. Capacitors are key parts in every circuit. These range from sensitive signal filters to voltage stabilizers. As a result, even small errors in a capacitor’s value cause big failures. For example, poor filtering or wrong circuit frequency can happen. System damage is also a risk. The Digital Capacitance Meter provides an accurate way to measure capacitor values. Engineers use this tool to check new capacitors. Moreover, maintenance staff use it to find aging and failing capacitors. This includes finding dried-out or leaky parts. However, all measurements must be truly accurate, especially for circuits needing tight limits. Therefore, routine Capacitance Meter Calibration is essential. Calibration checks the device’s accuracy against known standards. This ensures that component health judgments are always reliable.

1. What is a Capacitance Meter? Core Technical Applications

The Capacitance Meter is a specialized electronic instrument designed to provide fast, accurate, and repeatable measurements of a capacitor’s ability to store electrical charge. In addition, it helps engineers and technicians evaluate capacitor health, detect early signs of component aging, and verify performance in both new and existing circuits. As a result, it plays an essential role in electronics troubleshooting, circuit design, and preventive maintenance.

Moreover, a high-quality capacitance meter supports precise testing across a wide range of capacitance values, making it suitable for applications in consumer electronics, industrial systems, power supplies, and telecommunications. Therefore, using a reliable capacitance meter improves testing efficiency, reduces diagnostic errors, and supports consistent product quality. Ultimately, this makes the capacitance meter an indispensable tool in professional electronics and electrical testing environments.

1.1. Specialized Measurement Functionality

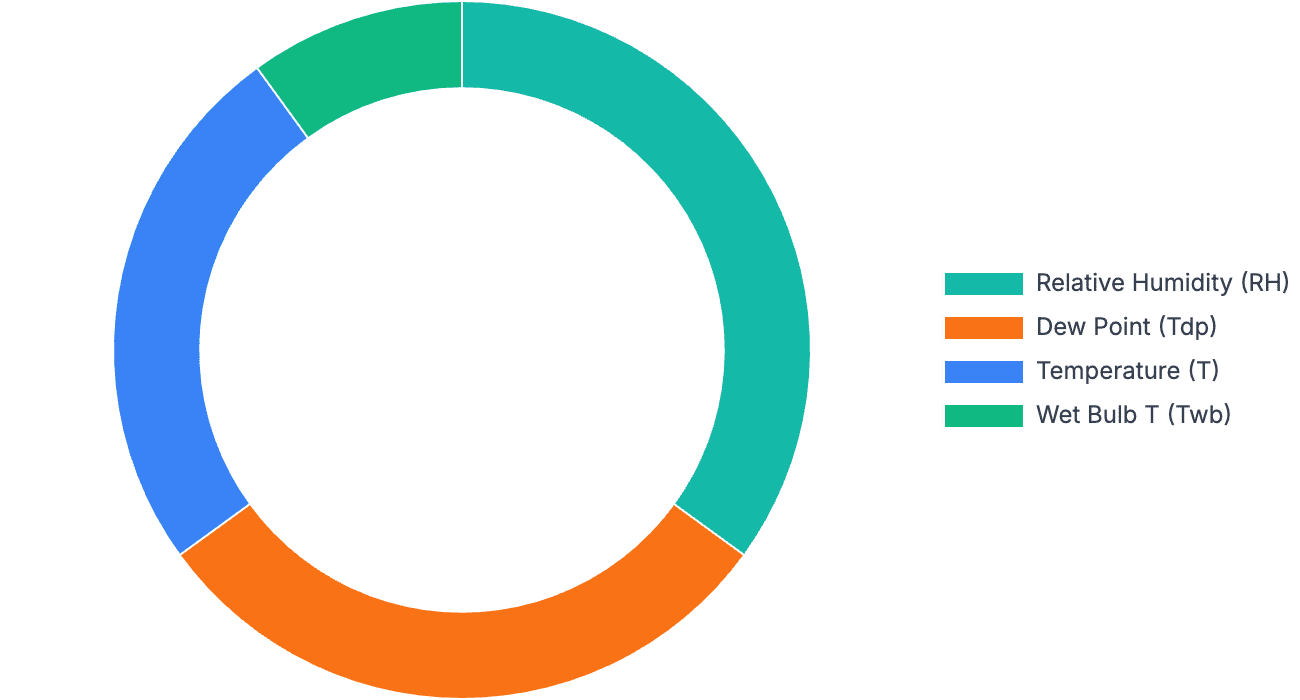

A hygro-thermometer measures multiple core and derived parameters requiring accuracy validation.

Relative Humidity (RH)

Direct quantity. Sensitive to contamination and aging.

Dew Point (Tdp)

Derived quantity. Key for condensation and corrosion risk.

Dry & Wet Bulb Temperature

Reference and evaporative cooling performance data.

Importance Weighting in Quality Control

This device works simply. First, it applies a known AC current to the capacitor. Then, it calculates the impedance or the charge/discharge time. Finally, it determines the capacitance value.

-

High-Accuracy Measurement: It offers a wide range, from picoFarads ($\text{pF}$) to milliFarads ($\text{mF}$). It provides high resolution, such as $0.1 \text{ pF}$, for sensitive uses.

-

Capacitor Quality Assessment: The meter helps staff classify capacitors by tolerance. It also finds major faults like short circuits or open circuits.

1.2. Critical Applications in Development and Manufacturing

-

Electronic Circuit Design (R&D): Engineers check actual capacitor values before building a prototype. This ensures the circuit works at the right frequency and filters signals correctly.

-

Capacitor Manufacturing: Manufacturers use the meter as the final Quality Control (QC) tool. It classifies capacitors by tolerance to meet sales specifications.

2. The Role of Accurate Capacitance in Industry

Accurate capacitance measurement is the difference between a stable circuit and a failed system.

2.1. Electronic Maintenance and Troubleshooting

-

Aging Capacitor Analysis: Capacitors (especially electrolytics) age over time. They lose capacitance and increase internal resistance (ESR). The Capacitance Meter helps maintenance teams quickly find dried or weak capacitors in expensive power supplies.

-

Telecom Equipment Repair: In high-frequency circuits, small changes in capacitance shift the operating frequency. Clearly, accurate measurement is the key to fixing performance issues.

2.2. Automation and Power Supply Systems

-

Power Supplies: Power supply capacitors handle high heat and heavy current. Measuring capacitance helps check the power supply’s output stability. This prevents sudden failures.

-

Noise Filtering Systems: You must ensure filter capacitors have the correct value. This protects equipment from electromagnetic interference (EMI/RFI).

3. The Absolute Need for Capacitance Meter Calibration

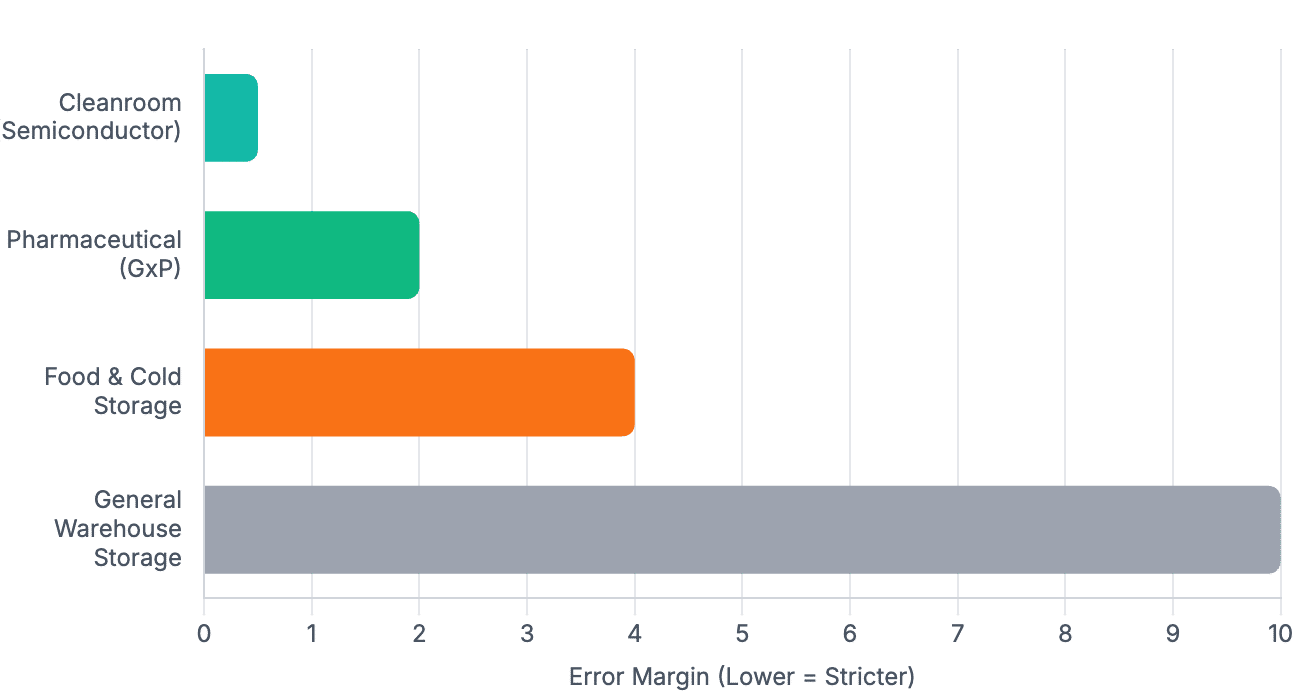

Each industry has strict requirements for the accuracy of humidity measurement. The smaller the error margin, the higher the risk.

Comparison of Humidity Error Margins (±% RH)

Cleanroom

±0.5% RH. Foundation for semiconductor and microelectronics.

Pharmaceutical

±2.0% RH. Directly impacts drug stability and shelf life.

General Warehouse

±10.0% RH. Applicable for storing less sensitive general goods.

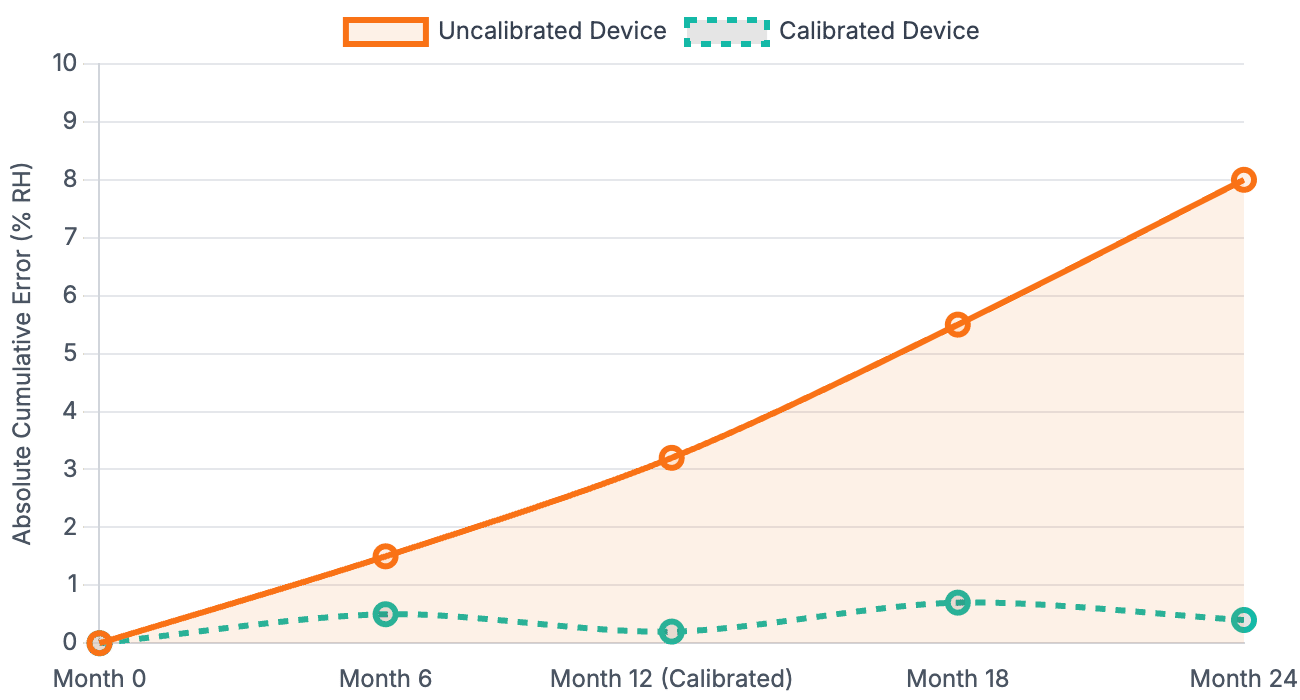

Sensor Drift Risk (Visual Simulation)

Many factors affect the meter’s accuracy. Therefore, calibration is necessary.

3.1. Preventing Systematic Error

-

Internal Factors: The meter’s accuracy relies on its internal parts. Specifically, the stability of the AC current and the internal circuit matter. Drift in these parts causes measurement errors.

-

Accuracy Verification: Calibration compares the test meter against certified Reference Capacitance Standards. This process finds and fixes systematic errors across all ranges.

3.2. Ensuring Final Product Integrity

-

Quality Standard Compliance: In electronic production meeting ISO or military rules, all vital tools must have a Traceable Calibration Certificate. Otherwise, wrong capacitance data could cause quality control to reject whole product batches.

-

Transparency and Reliability: The Calibration Certificate proves that the device’s capacitance values are trustworthy. In fact, this serves as valid proof during quality audits or warranty claims.

4. Professional Capacitance Calibration Procedure

1. Standards Setup

Use ISO 17025 traceable references.

2. Data Comparison

Record multi-point as-found data.

3. Adjustment & Report

Issue certificate with corrections.

Calibration uses a careful process to maintain precision.

-

Reference Standards: Technicians use a set of High-Precision Capacitance Standards. These standards have certified tolerance and traceability to national standards.

-

Test and Comparison: The technician measures each value on the reference standards. They use the Capacitance Meter across several ranges. Then, they compare the reading against the standard’s value.

-

Adjustment and Confirmation: If the error is too large, the technician adjusts the device. If not, they record a correction factor. They also calculate Measurement Uncertainty.

-

Certification: Finally, the lab issues a Calibration Certificate. This confirms the device’s accuracy and gives the next calibration due date.