Glass Thermometer Calibration remains a critical requirement in many laboratories and industries, even as digital temperature sensors become increasingly popular. Liquid-in-glass thermometers are still widely used due to their simplicity, stability, and independence from electronic drift. However, without proper calibration, these instruments can introduce significant measurement errors, affecting product quality, process control, and regulatory compliance.

This article provides a comprehensive overview of glass thermometer calibration, explaining not only how calibration is performed, but also why it matters, which standards apply, and how professional calibration services like Techmaster help organizations maintain accuracy and audit readiness.

What Is Glass Thermometer Calibration?

Glass thermometer calibration is the process of comparing the readings of a glass thermometer against a traceable reference standard to determine its measurement accuracy across specific temperature points.

It is important to distinguish between calibration and adjustment:

-

Calibration evaluates and documents measurement error.

-

Adjustment attempts to physically alter the instrument to correct the error, which is typically not possible with glass thermometers.

Calibration ensures that temperature readings are reliable, traceable, and suitable for their intended application.

Types of Glass Thermometers and Calibration Implications

Glass thermometers fall under the broader category of liquid-in-glass thermometers, and their characteristics directly influence calibration results.

Common Types

-

Mercury-in-glass thermometers

Known for high stability and repeatability, suitable for higher temperature ranges. -

Alcohol or organic liquid thermometers

Typically used for lower temperature ranges, with higher sensitivity to environmental conditions.

Calibration Considerations

Different liquid types affect:

-

Measurement range

-

Stability and drift behavior

-

Readability and resolution

-

Achievable measurement uncertainty

Understanding the thermometer type is essential for selecting appropriate calibration methods and acceptance criteria.

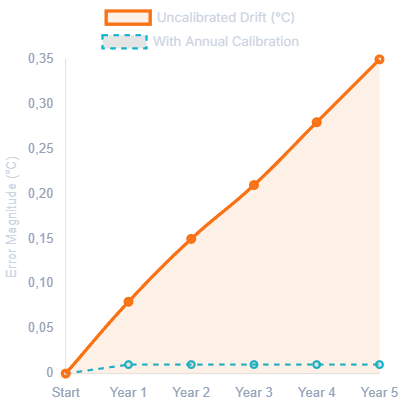

Why Calibration Matters: The Drift Effect

Glass is an amorphous solid, not a true solid. Over time, the bulb volume changes slightly as the glass settles, a phenomenon known as “secular change.” In high-precision environments like pharmaceutical or petrochemical labs, this microscopic shift results in significant temperature drift.

Key Insight

Without annual calibration, a standard lab thermometer can drift by up to 0.1°C per year, potentially violating ASTM E1 standards.

Figure 1: Projected drift of uncalibrated glass vs. calibrated correction over 5 years.

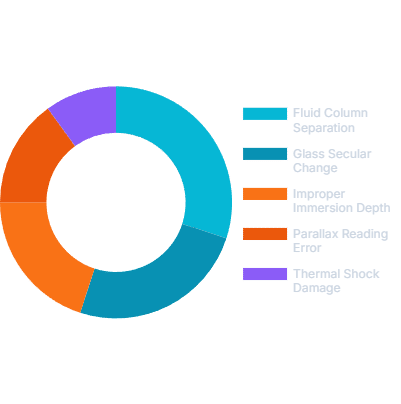

Common Sources of Inaccuracy

While glass aging is inevitable, human error and physical damage contribute significantly to false readings. Understanding these factors is the first step in establishing a robust Quality Assurance program.

- Liquid Separation: Gas bubbles trapped in the mercury or spirit column.

- Immersion Errors: Reading a partial immersion thermometer as total immersion.

- Parallax: Viewing the meniscus from an angle rather than eye-level.

Figure 2: Distribution of calibration failure causes in industrial settings.

Calibration Standards and Traceability

Professional glass thermometer calibration must comply with recognized international standards.

Commonly Applied Standards

-

ISO/IEC 17025 – General requirements for the competence of testing and calibration laboratories

-

ASTM E1 / ASTM E77 – Specifications and test methods for liquid-in-glass thermometers

-

ITS-90 – International Temperature Scale of 1990

Traceability

Calibration results must be traceable to national or international standards, such as those maintained by NIST or equivalent national metrology institutes. Traceability ensures confidence in measurement results and is a core requirement during audits.

Common Sources of Error in Glass Thermometers

Despite their simple construction, glass thermometers are subject to several error sources.

Typical Error Factors

-

Glass aging and drift over time

-

Immersion depth errors, especially when total immersion conditions are not met

-

Parallax error caused by incorrect viewing angle

-

Liquid column separation, common after thermal shock

-

Environmental influences, such as vibration or rapid temperature changes

Identifying these factors helps explain why periodic calibration is necessary and why visual inspection alone is insufficient.

The Ice Point Method

The most common field check for glass thermometers is the Ice Point (0°C / 32°F) verification. This non-destructive method provides an immediate reference point.

Visual Inspection

Check for cracks, separated liquid columns, and legible etched gradations.

Prepare Bath

Create a slurry of crushed ice and distilled water. No floating ice chunks.

Immerse & Stabilize

Insert thermometer to immersion line. Wait 3 mins for thermal equilibrium.

Record Offset

Record difference from 0°C. Apply this correction factor to future readings.

Understanding Measurement Uncertainty in Calibration

Measurement uncertainty is a critical concept often misunderstood or overlooked.

What Is Measurement Uncertainty?

It represents the range within which the true value of the measurement is expected to lie, considering all known sources of error.

Main Contributors

-

Reference thermometer uncertainty

-

Temperature stability of the calibration bath

-

Resolution and readability of the glass thermometer

-

Repeatability of readings

Measurement uncertainty is essential for evaluating whether a thermometer meets its acceptance criteria and for demonstrating compliance during audits.

Acceptance Criteria and Tolerance Evaluation

After calibration, results must be assessed against defined acceptance criteria.

Common Evaluation Bases

-

Manufacturer specifications

-

Process or application tolerance

-

Customer-defined requirements

A thermometer may show measurable deviation yet still be acceptable if it falls within specified tolerances. Professional calibration reports clearly indicate pass or fail status based on agreed criteria.

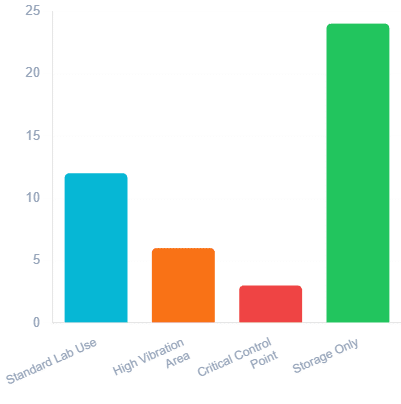

Recommended Calibration Intervals

Calibration frequency is not a “one size fits all” metric. It depends on usage intensity, the critical nature of the measurement, and historical drift data.

📅

Annual (Standard)

Baseline for most ISO 17025 accredited labs.

⚠️

Semi-Annual (High Risk)

Required for thermometers subjected to thermal shock or vibration.

✅

Before Critical Use

One-point checks (Ice Point) recommended before critical validations.

When to Calibrate vs When to Replace a Glass Thermometer

Calibration is not always the most effective solution.

Consider Replacement When:

-

Drift exceeds acceptable limits

-

Physical damage is observed

-

Measurement uncertainty becomes too high

-

Cost of calibration outweighs replacement benefits

Techmaster supports clients by providing technical advice to help determine the most practical and compliant option.

Applications Across Industries

Glass thermometer calibration remains relevant in many sectors:

-

Laboratories and research facilities

-

Food and beverage production

-

Pharmaceutical and biotech manufacturing

-

Industrial temperature monitoring

Each application has unique requirements that influence calibration range, uncertainty, and acceptance criteria.

How to Read and Verify a Calibration Certificate

A calibration certificate is more than a formality.

Key Elements to Review

-

Instrument identification

-

Calibration results at each point

-

Measurement uncertainty

-

Traceability statement

-

Accreditation marks and authorized signatures

Incomplete or unclear certificates may lead to audit findings, even if calibration was technically performed.

Techmaster’s Glass Thermometer Calibration Capability

Techmaster provides professional glass thermometer calibration services designed to meet international standards and customer-specific requirements.

Key Strengths

-

Calibration performed in accordance with ISO/IEC 17025 principles

-

Traceable reference standards

-

Clear, audit-ready calibration certificates

-

Technical consultation on calibration intervals and acceptance criteria

By working with Techmaster, organizations gain confidence that their temperature measurements are accurate, reliable, and compliant.

Conclusion

Glass thermometer calibration remains a vital component of accurate temperature measurement and quality assurance. Understanding calibration principles, standards, uncertainty, and acceptance criteria enables better decision-making and stronger compliance.

With experienced laboratories like Techmaster, organizations can ensure their glass thermometers continue to deliver reliable performance, supporting both operational excellence and regulatory confidence.