Gas Analyzers: Optimizing Combustion Efficiency and the Vital Role of Gas Analyzer Calibration

As energy management and environmental protection become global priorities, monitoring the components of combustion exhaust is more critical than ever. A Gas Analyzer serves as an essential tool for HVAC engineers and boiler technicians, allowing them to precisely determine the concentrations of O2, CO, CO2, NO/NOx. However, these parameters only remain useful if the device provides accurate data. Consequently, performing regular Gas Analyzer Calibration is a non-negotiable requirement for system safety and operational efficiency. This article explores the vital applications of these devices and explains why professional calibration is the foundation of reliable measurement.

1. How Does a Gas Analyzer Work?

In essence, a gas analyzer is a sophisticated measurement instrument that employs electrochemical or infrared sensors to detect and quantify specific gases within a mixture.

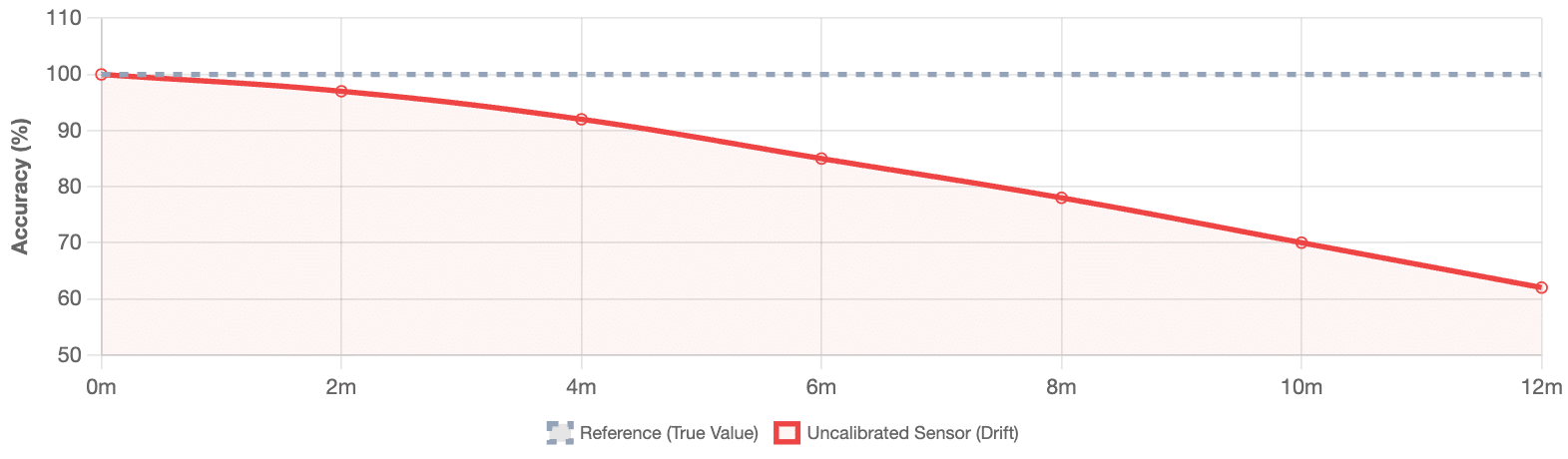

Initially, the device extracts a gas sample from a flue or the surrounding environment through a specialized probe. The sample is then conditioned—filtered and cooled if necessary—before being delivered to the internal sensors. At this stage, a chemical or physical reaction occurs within the sensor, generating an electrical signal that is directly proportional to the gas concentration. However, because these sensors are continuously exposed to corrosive gases, moisture, and extreme temperatures, their sensitivity and accuracy inevitably degrade over time. Consequently, regular Gas Analyzer Calibration is essential to realign sensor responses, compensate for drift, and ensure the analyzer continues to deliver precise and reliable measurements.

2. Key Industrial Applications of Gas Analyzers

Combustion Optimization

Life Safety & CO Monitoring

Medical Gas Analysis

Environmental Compliance

Gas analyzers are much more than simple meters; they act as safety and efficiency assistants across multiple sectors:

2.1. Optimizing Combustion Performance

The most common application involves testing furnaces, boilers, and industrial burners. By analyzing the excess oxygen ratio and carbon monoxide levels, technicians can adjust the fuel-to-air ratio. This optimization not only reduces energy costs but also ensures complete combustion, which minimizes soot buildup and equipment wear.

2.2. Life Safety and CO Poisoning Prevention

Carbon Monoxide ($CO$) is a “silent killer” because it is colorless and odorless. Gas analyzers detect even the smallest $CO$ leaks in buildings or manufacturing zones. Furthermore, constant monitoring with a calibrated device prevents tragic poisoning accidents and protects worker health.

2.3. Environmental Emission Control

Strict environmental regulations require businesses to monitor greenhouse gases and acid rain precursors like $SO_2$ and $NO_x$. By using a gas analyzer, companies can generate accurate reports for regulatory bodies. This transparency helps avoid heavy fines resulting from emission standard violations.

2.4. HVAC System Diagnostics and Maintenance

In the heating and cooling industry, these tools help diagnose the health of heating systems. For instance, technicians can quickly detect cracks in a heat exchanger by observing changes in gas concentrations. Consequently, they can perform repairs before a minor issue turns into a catastrophic failure.

3. Why is Gas Analyzer Calibration Indispensable?

If a meter provides incorrect data, the entire system adjustment process becomes meaningless and potentially dangerous. Therefore, Gas Analyzer Calibration is a mandatory requirement for the following reasons:

-

Compensating for Sensor Drift: Electrochemical sensors age naturally due to chemical reactions or exposure to high gas concentrations. Calibration resets the “Zero point” and the “Span” of the sensor to account for this drift.

-

Ensuring Accuracy in Real-World Conditions: Variations in ambient temperature and humidity can influence measurement results. A professional calibration procedure simulates these conditions to ensure the device remains stable in the field.

-

Compliance with Safety Standards (OSHA, EPA): Environmental and safety organizations require measuring equipment to hold valid calibration certificates. This documentation ensures that the data is legally defensible and professionally recognized.

-

Extending Equipment Lifespan: Periodic calibration often includes cleaning the dust filters and checking the sampling pump. These actions help the device run smoothly and reduce the need for expensive component replacements.

4. The Professional Gas Analyzer Calibration Procedure

Step 1 — Zero Calibration

Expose sensor to zero gas (N₂ or filtered air) to establish baseline.

Step 2 — Span Adjustment

Apply certified calibration gas with known concentration.

Step 3 — Verification

Confirm linearity, response time, and repeatability.

Step 4 — Certification

Issue traceable certificate and label next calibration date.

A standard Gas Analyzer Calibration involves several rigorous technical steps:

-

Zeroing the Device: The technician uses fresh air or pure Nitrogen to establish a baseline (zero level) for the sensors.

-

Span Calibration with Reference Gases: Next, the device is exposed to a certified gas mixture with an exactly known concentration.

-

Software Adjustment: The technician adjusts the device’s gain settings so the displayed value matches the reference gas value.

-

Certification: Finally, the laboratory issues a formal certificate recording the “As-Found” and “As-Left” data, providing full traceability.

5. Maintenance Tips to Sustain Accuracy After Calibration

To maintain the results of your Gas Analyzer Calibration for as long as possible, users should adopt these habits:

-

Purge with Fresh Air: After every measurement, run the device in “Fresh Air” mode for a few minutes. This flushes corrosive gases out of the sensor chamber.

-

Replace Moisture Filters Regularly: Water vapor is the enemy of electrochemical sensors. Always ensure the water trap and filters are functioning correctly.

-

Protect from Physical Shock: The optical and chemical components inside the analyzer are sensitive to impact. Store the device in a padded, specialized carrying case.

Conclusion

In summary, a gas analyzer is a smart investment for any business focused on efficiency, sustainability, and safety. However, the true value of this tool depends entirely on its precision and long-term reliability. Committing to regular Gas Analyzer Calibration is not merely a regulatory requirement—it is a proactive strategy to minimize risk, ensure compliance, and maintain consistent operational performance. Accurate measurements help protect the environment, safeguard employees, and prevent costly errors that can impact productivity and profitability. By ensuring your equipment is calibrated and verified by trusted experts, you can have complete confidence that the data guiding your decisions reflects the absolute truth and supports sustainable business growth.