In the world of high-stakes electronics manufacturing, static electricity is a silent killer. A single electrostatic discharge (ESD) event can compromise sensitive semiconductors, leading to latent defects or immediate catastrophic failure. To prevent this, quality engineers rely on Surface Resistance Test Kits. However, your ESD control program is only as reliable as the tools you use to measure it. If your equipment drifts out of spec, you aren’t just measuring incorrectly—basing your production safety on “ghost” data. This is where professional Surface Resistance Test Kit calibration becomes the backbone of your quality assurance. In this guide, we will explore why Surface Resistance Meter Calibration is critical for ANSI/ESD S20.20 compliance, how to handle specialized equipment like the Monroe Electronics 292, and what you should look for in a NIST-traceable calibration certificate.

Technical Overview: What is a Surface Resistance Test Kit?

Before diving into the calibration process, it is essential to define the “entity” of a test kit. Many users mistakenly believe they are only sending a “meter” to the lab. In reality, a Surface Resistance Test Kit is a precision system consisting of four vital components:

1. The Digital Megohmmeter (The Brain)

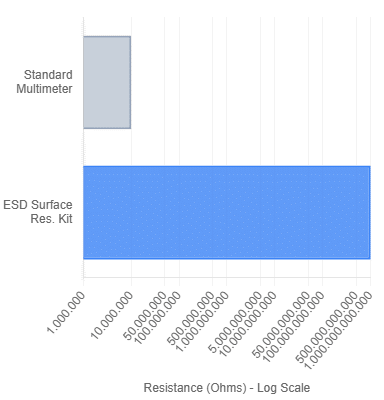

The heart of the kit is a high-resistance digital megohmmeter. Unlike standard multimeters, these devices must measure a massive range—typically from $10^3 \Omega$ to $10^{12} \Omega$. For accurate Surface Resistivity Meter Calibration, the device must automatically switch test voltages: 10V for conductive surfaces and 100V for dissipative materials (at the $1 \times 10^6 \Omega$ threshold).

2. Weighted Electrodes (The Probes)

Standard kits include two 5lb (2.27 kg) electrodes. These probes are engineered to simulate consistent contact pressure on ESD mats, flooring, and tabletops. The conductive rubber pads on these weights are subject to hardening and contamination, which can drastically skew your readings.

3. Shielded Test Leads

At high resistances ($> 10^9 \Omega$), ambient electromagnetic interference can cause fluctuations. Shielded leads ensure that the current measured is actually passing through the material, not through the air or the technician’s body.

4. Integrated Environmental Sensors

Advanced models like the Monroe Electronics 292 or Desco kits feature built-in Temperature and Relative Humidity (RH) sensors. Because surface resistance is inversely proportional to humidity, these sensors must be calibrated alongside the resistance circuitry to ensure valid data logging for your audits.

1. Calibration vs. Verification: Do You Know the Difference?

Why can’t you use a regular multimeter? Standard meters cap out around 10 Megaohms (10⁷Ω). ESD compliance requires measuring up to 1 Teraohm (10¹²Ω). That is a difference of 100,000x.

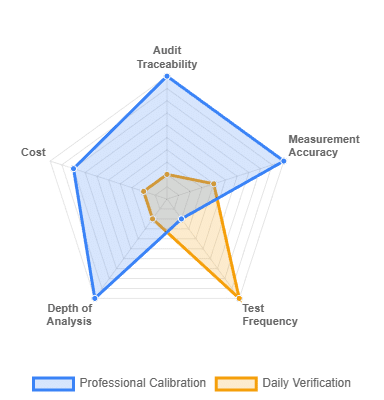

Daily Verification is a quick “alive check” on the factory floor. Professional Calibration is a deep-dive analysis against NIST standards in a lab. You need both.

A common point of confusion in ESD audits is the difference between “Verification” and “Calibration.”

-

Daily Verification: This is a functional check. Using a “Verification Box,” a technician ensures the meter isn’t “dead” and that it roughly reads a known resistor. This is performed on the factory floor.

-

Professional Calibration: This is a deep-dive laboratory process. It involves comparing the meter’s performance against laboratory-grade standards with known uncertainties.

Why does this matter? Verification proves the tool is working today; professional Surface Resistance Test Kit calibration provides the legal and technical “traceability” required to pass an ISO 9001 or ANSI/ESD S20.20 audit.

2. The Core Protocol: The Science of High-Resistance Testing

When we perform Surface Resistance Meter Calibration, we follow a rigorous protocol that mimics real-world ESD scenarios while adhering to laboratory precision.

The 10V/100V Switching Logic

According to ESD standards, the test voltage significantly impacts the resistance measurement. A professional lab validates that the meter accurately switches from 10V to 100V exactly when it should. If your meter applies 100V to a conductive surface, it could spark or provide a false low reading.

The 15-Second Electrification Rule

In high-resistance testing, the current is incredibly small (pico-amps). It takes time for the current to stabilize across the material’s surface. This is known as the “soak time” or electrification period. During calibration, we verify that the meter’s internal timer (if it has one, like the Monroe Electronics 292) accurately waits 15 seconds before locking in a final measurement.

3. “Beyond the Meter”: Why Accessories Matter

One of the most significant value-adds of a professional service is the calibration of the accessories. If you only calibrate the “box” and not the “kit,” you are leaving a massive gap in your quality control.

Electrode Integrity (The 5lb Weights)

We inspect the durometer (hardness) of the electrode pads. Over time, rubber can oxidize and harden, or absorb oils from the factory floor. We measure the resistance of the electrode itself to ensure it contributes negligible error to your material tests.

Lead Resistance

Even the highest-quality leads can develop internal breaks or insulation degradation. We test the continuity and insulation of your cables to ensure they aren’t acting as “antennas” for noise.

4. The “Humidity Factor” in Surface Resistivity Meter Calibration

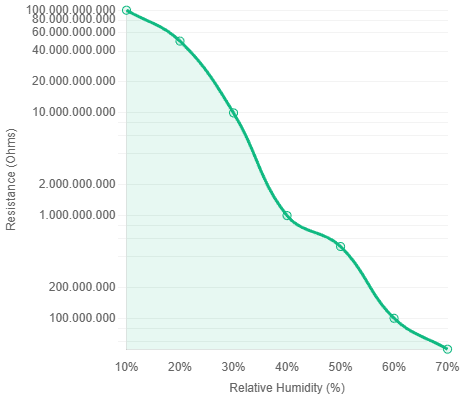

Environment is everything. Surface resistance is inversely proportional to humidity.

Moisture creates a conductive layer on surfaces. Materials may read more conductive (Lower Resistance) than they actually are.

Dry air increases resistance. This is the danger zone for ESD. Materials become more insulative, holding static charges longer.

Calibration Note: We calibrate the kit’s internal RH sensor against a primary hygrometer to ensure your environmental data is valid for audits.

Environment is everything. Surface resistance is highly sensitive to moisture. In a dry environment, surfaces become more resistive (more dangerous for ESD). In a humid environment, surfaces become more conductive.

Professional Surface Resistivity Meter Calibration must be performed in a climate-controlled laboratory. We monitor and record the exact ambient temperature and humidity during the test. For specialized units like the Monroe Electronics 292, we calibrate the internal RH sensor against a primary hygrometer. This ensures that when your meter says “30% RH,” it is actually 30%, allowing your engineers to make informed decisions about floor treatments or humidity controls.

5. Interpreting Your Calibration Certificate: What Auditors Look For

When an auditor asks for your calibration records, they are looking for more than just a “Passed” sticker. A high-quality NIST-traceable certificate should include:

-

NIST Traceability Number: Proof that the laboratory’s standards are linked back to the National Institute of Standards and Technology.

-

As-Found vs. As-Left Data: This shows how much the meter drifted during the year. If the “As-Found” data was way out of spec, you may need to recall products tested with that meter.

-

Measurement Uncertainty: Every measurement has a margin of error (e.g., ±2%). A professional lab calculates this “Uncertainty Budget” to provide a confidence level (usually $k=2$ or 95%).

-

ISO 17025 Accreditation: While not always mandatory, using an ISO 17025 accredited lab for your Surface Resistance Test Kit calibration provides the highest level of international recognition.

6. Focus on the Monroe Electronics 292

The Monroe Electronics 292 is a gold standard in the industry, often referred to as the “Static Meter for Professionals.” Because of its high accuracy and integrated sensors, it requires a more sophisticated calibration approach than “budget” meters.

-

Multi-Point Calibration: We don’t just test one resistor. We test multiple points across the entire $10^3$ to $10^{12}$ decade range.

-

Sensor Calibration: The 292’s ability to display Temp/RH alongside resistance makes it a “three-in-one” device. We calibrate all three parameters simultaneously.

Conclusion: Protecting Your Production Floor

Accuracy in ESD control is not a luxury—it is the foundation of modern electronics manufacturing. Using an uncalibrated or improperly calibrated Surface Resistance Test Kit exposes your company to failed audits, expensive product recalls, and a tarnished reputation.

By investing in professional, NIST-traceable Surface Resistance Meter Calibration, you ensure that your measurements are accurate, your accessories are functional, and your facility remains in total compliance with ANSI/ESD S20.20 standards.

Using an uncalibrated kit exposes you to failed audits and product recalls. Ensure your facility remains in total compliance with ANSI/ESD S20.20 standards.

Infographic generated for educational purposes on Surface Resistance Meter Calibration.

Based on technical guide data.