Digital Vacuum Gauges: Comprehensive Applications and the Critical Necessity of Lcd Vacuum Gauge Calibration

In the world of high-precision engineering, the “unseen” often matters most. For HVAC technicians, laboratory researchers, and industrial manufacturers, the quality of a vacuum can determine the success or failure of a project. A digital LCD vacuum gauge is the primary tool used to monitor these invisible environments. However, measuring a deep vacuum is a complex task. Even the most advanced sensors can drift over time. This is why Lcd Vacuum Gauge Calibration is a fundamental requirement for any professional operation.

1. Vacuum Measurement and How it works?

Electrical pulses from sensors or switches.

Each pulse = +1 unit. Basic noise filtering.

The number you see.

1.1. The Evolution of Vacuum Measurement

For decades, technicians relied on analog gauges to monitor pressure. However, analog tools lack the resolution needed for modern “deep vacuum” requirements. A deep vacuum is often measured in microns. To put this in perspective, one micron is $1/1000$ of a millimeter of mercury.

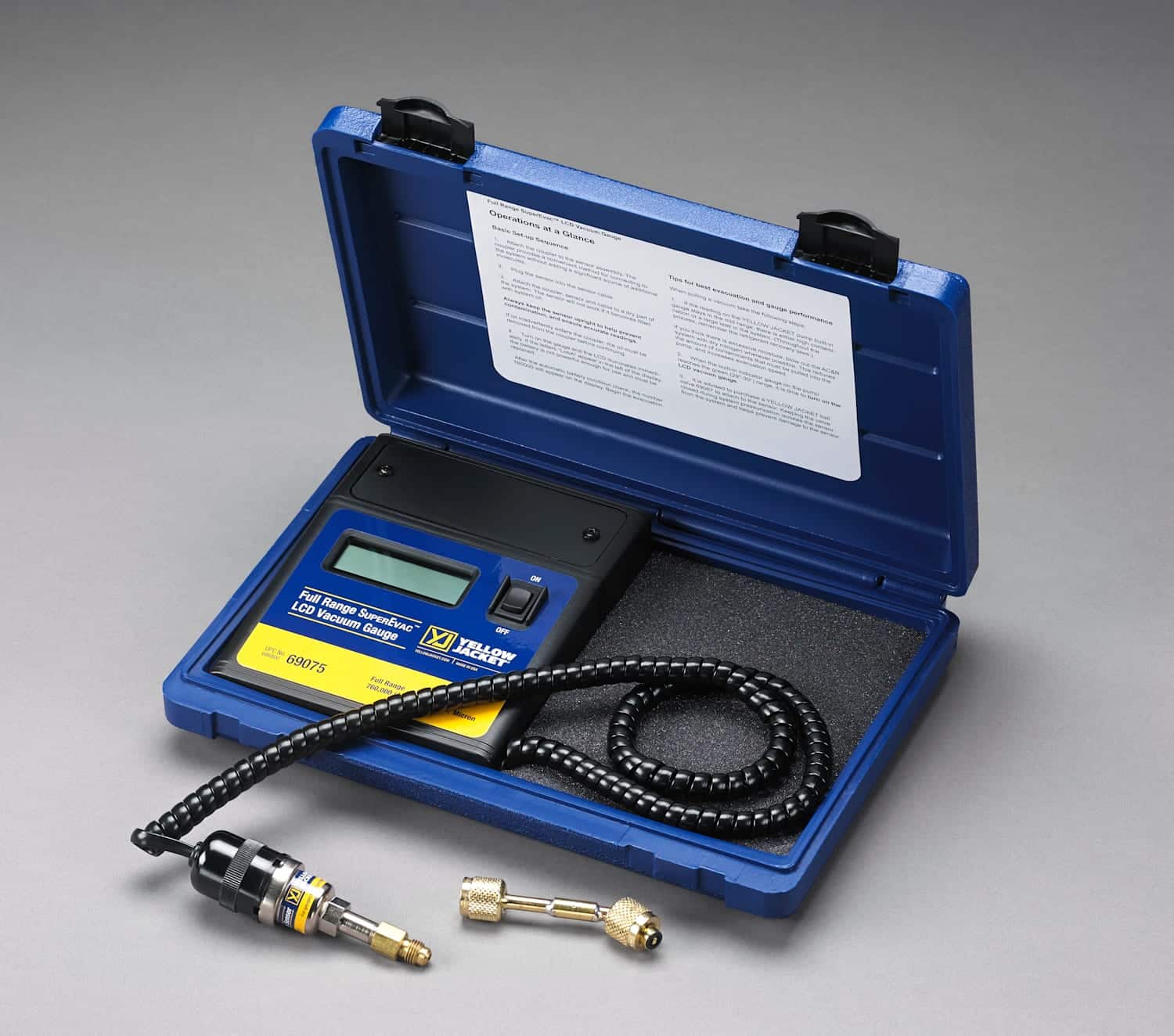

Modern digital gauges with LCD screens have revolutionized this field. They offer instant, precise readings that are easy to see in dark work environments. These devices allow users to track the evacuation process in real-time. Yet, as the technology becomes more sensitive, the need for precision increases. This brings us to the core requirement of the industry: ensuring accuracy through Lcd Vacuum Gauge Calibration.

1.2. Technical Principles: How LCD Vacuum Gauges Operate

To appreciate the value of calibration, one must understand how these sensors function. Most digital vacuum gauges do not “weigh” the air. Instead, they often use thermal conductivity sensors, such as Pirani or Thermocouple sensors.

The Thermal Conductivity Method

The device contains a small internal wire that is heated. As the vacuum pump removes air molecules, there are fewer particles to carry heat away from the wire. The sensor measures the temperature of this wire to determine the pressure.

The Role of the Microprocessor

The internal microprocessor then converts these thermal changes into a digital value. This value is what appears on the LCD. However, this process is highly sensitive. Small amounts of oil, dust, or moisture can coat the sensor wire. When this happens, the heat transfer changes, and the display shows a wrong number. Regular Lcd Vacuum Gauge Calibration is the only way to reset these parameters and ensure the microprocessor interprets the sensor’s signals correctly.

2. Industrial Applications of LCD Vacuum Gauges

Counting items on conveyors

Machine run-time

(hour meter)

Flow pulse counting

People / vehicle counting

Digital vacuum gauges are versatile tools used across various high-stakes industries.

2.1. HVAC and Refrigeration (HVAC/R)

This is perhaps the most common application. When a technician installs an air conditioner, they must evacuate the system. Moisture is the enemy of any cooling system. If water stays inside, it can freeze and block valves. It can also mix with refrigerant to form acid, which destroys the compressor. An LCD vacuum gauge tells the technician exactly when the system is dry. Usually, a target of 500 microns is required. Without Lcd Vacuum Gauge Calibration, a technician might think they have reached 500 microns when they are actually at 1,000 microns.

2.2. Freeze-Drying (Lyophilization)

The food and pharmaceutical industries use vacuum technology to dry products. In freeze-drying, water is removed from a product through sublimation. This requires an extremely stable and deep vacuum. If the vacuum gauge is inaccurate, the product might not dry correctly. This could lead to spoiled food or ineffective medicine.

2.3. Semiconductor and Electronics Manufacturing

The production of microchips happens in “clean rooms” and vacuum chambers. Thin-film deposition requires a vacuum to ensure that layers of material are applied evenly. Even a tiny deviation in pressure can ruin a batch of semiconductors. In this field, Lcd Vacuum Gauge Calibration is often performed on a strict monthly or quarterly schedule to prevent multi-million dollar losses.

2.4. Automotive Engineering

Modern cars use vacuum systems for brake boosters and emissions control. Manufacturers use digital gauges to test the integrity of these systems during the assembly process. Accuracy here is a matter of safety.

3. Why is Lcd Vacuum Gauge Calibration Necessary?

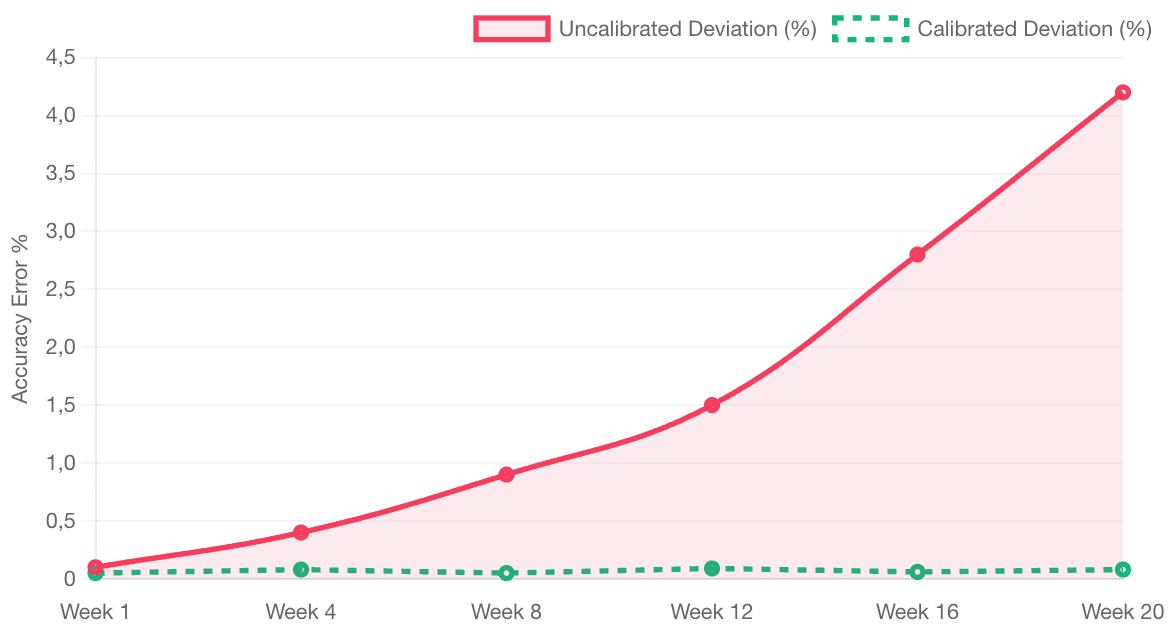

Error Rate: Calibrated vs. Uncalibrated

Many users ask: “If my gauge is digital, why does it need calibration?” The answer lies in the harsh environments where these tools work.

3.1. Sensor Contamination

In the field, vacuum gauges are often exposed to pump oil. If the technician shuts off the pump without closing a valve, oil can spray into the sensor. This oil acts as an insulator. It changes how heat moves away from the sensor wire. Consequently, the gauge will provide a “drifted” reading.

3.2. Environmental Factors

Changes in ambient temperature and humidity can affect the electronic components inside the gauge. Over time, resistors and capacitors age. This aging changes the voltage signals within the device. Lcd Vacuum Gauge Calibration accounts for these changes and re-aligns the device to a known standard.

3.3. Compliance and Traceability

In many industries, you must prove your work is accurate. If you are a contractor for a hospital or a government facility, they will ask for a Calibration Certificate. This document proves that your LCD vacuum gauge has been tested against a standard traceable to national institutes like NIST. Without this, your work may not be legally or professionally accepted.

4. The Professional Calibration Procedure

Display and buttons

Exactly 1,000 pulses

1000 = OK, 1005 = adjust

Apply ISO label

What happens during a professional Lcd Vacuum Gauge Calibration? It is a multi-step process conducted in a controlled laboratory.

-

Initial Cleaning: The technician first cleans the sensor port with high-purity isopropyl alcohol. This removes any oil or debris.

-

Atmospheric Stabilization: The gauge is allowed to sit in the lab environment to reach a stable temperature.

-

The Master Standard: The lab uses a “Master Gauge.” This is a reference tool that is ten times more accurate than the gauge being tested.

-

The Vacuum Chamber Test: Both the master gauge and the customer’s gauge are connected to a high-quality vacuum pump.

-

Multi-Point Verification: The technician tests the gauge at several specific levels. For example, they might check 5,000, 1,000, 500, 250, and 50 microns.

-

Adjustment: if the gauge allows it, the technician will adjust the internal software to match the master standard.

-

Final Documentation: The lab issues a certificate showing the “As-Found” (before) and “As-Left” (after) data.

5. Maintenance: Keeping Your Gauge Accurate

You can extend the life of your Lcd Vacuum Gauge Calibration by following a few simple steps.

-

Use a Shut-off Valve: Always install a valve between the gauge and the system. Close it before turning off the vacuum pump. This prevents oil from backing up into the sensor.

-

Store Vertically: When not in use, store the gauge with the sensor port facing down. This allows any trapped oil to drain out.

-

Regular Cleaning: If your readings become “sluggish,” clean the sensor with alcohol. Let it dry completely before using it again.

-

Avoid High Pressure: Never apply positive pressure to a vacuum gauge. Most sensors are designed for vacuum only. High pressure can permanently damage the delicate sensor wire.

Conclusion

The digital LCD vacuum gauge is a masterpiece of modern measurement. It provides the clarity and precision needed to handle the most demanding technical tasks. However, its accuracy is not a permanent feature. It is a condition that must be maintained.

Investing in regular Lcd Vacuum Gauge Calibration is the hallmark of a professional. It protects your equipment, ensures the quality of your work, and gives you peace of mind. In a world where microns matter, make sure your numbers are the truth.