In the world of high-voltage electrical maintenance, precision isn’t just a technical requirement—it is a safety mandate. Whether you are testing utility-scale transformers, underground cables, or industrial switchgear, the integrity of your results depends entirely on the accuracy of your equipment.

However, even the most robust AC Dielectric Test Set can drift over time due to environmental stress, component aging, or physical handling during field use. This is where professional AC Dielectric Test Set Calibration becomes critical. In this guide, we will explore the technical nuances of calibration, the benefits of on-site services, and why specialized models like the PFT-503CM require a specific approach to maintain NIST traceability.

1. AC Dielectric Test Set vs. Benchtop Hipot: Understanding the Scale

Before diving into the calibration process, it is important to distinguish the equipment. While many technicians use the terms interchangeably, an AC Test Set (often referred to as an AC Dielectric Test Set) typically refers to high-capacity, field-portable, or stationary systems used for heavy-duty insulation testing.

Unlike small benchtop Hipot testers used in electronics manufacturing, AC Dielectric Test Sets are designed to provide the high kVA (kilovolt-ampere) required to charge the capacitance of large electrical apparatus. Because these systems operate in rugged environments—substations, construction sites, and industrial plants—their internal components are subject to more significant wear and tear, making regular AC Test Set Calibration a non-negotiable part of your maintenance cycle.

Internal Note: If you are looking for information on smaller production-line units, see our companion guide on Hipot Tester Calibration.

2. Core Technical Parameters: What Happens During Calibration?

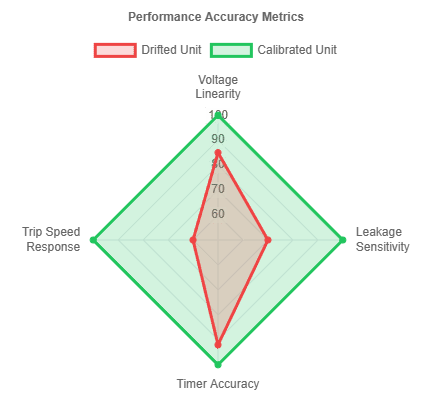

We verify the physics behind the measurement across four critical pillars.

1. Voltage Linearity

Verifying output remains linear (25%, 50%, 75%, 100%) using high-precision dividers.

2. Leakage Sensitivity

Calibrating micro-ampere (μA) meters to ensure failing insulators are detected.

3. Fault Trip Response

Simulating flashovers to ensure safety circuits trip within milliseconds.

Equipment Health: Drifted vs. Calibrated

A visualization of how “Drift” skews safety metrics away from the ideal standard.

A professional calibration laboratory doesn’t just “check” the numbers; they verify the physics behind the measurement. When we perform AC Dielectric Test Set Calibration, we focus on four critical pillars:

Voltage Linearity and Accuracy

We verify that the kilovolt ($kV$) output remains linear across the entire range of the instrument. Using a high-precision voltage divider and a calibrated voltmeter, we measure the actual output against the displayed value at 25%, 50%, 75%, and 100% of the unit’s capacity.

Leakage Current Sensitivity

The primary job of a dielectric test is to detect leakage current. If the meter is insensitive, you might miss a failing insulator. We calibrate the current meter—often in the micro-ampere ($\mu A$) or milli-ampere ($mA$) range—to ensure that when the equipment signals a “Pass,” it is truly based on accurate leakage data.

Dwell Timer Verification

Most NETA and IEEE standards require a specific duration for withstand tests (e.g., 60 seconds). If your internal timer is off by even a few seconds, you are out of compliance. We verify the accuracy of the integrated timers to ensure every test meets the regulatory “dwell time.”

Fault Trip Response

Safety is paramount. We simulate a flashover or insulation breakdown to ensure the system’s “overload” or “trip” circuit engages within the millisecond timeframe specified by the manufacturer.

3. Spotlight: High Voltage PFT-503CM Calibration

The PFT-503CM by High Voltage, Inc. (HVI) is the “workhorse” of the U.S. electrical testing industry. Known for its ruggedness and dual-range meters, it is the go-to portable AC Hipot for field testing.

However, High Voltage PFT-503CM Calibration requires specialized knowledge. These units often feature analog or digital-analog hybrid meters that are susceptible to parallax errors or magnetic interference. Our calibration protocol for the PFT-503CM includes:

-

Zero-Check Adjustment: Ensuring the mechanical zero on the meters is perfectly aligned.

-

Guard Circuit Verification: Testing the guard circuit to ensure it is correctly bypassing stray leakage currents, which is vital for high-accuracy field measurements.

-

Oil-Insulated Transformer Inspection: Checking for signs of oil degradation in the HV tank that could lead to internal arcing.

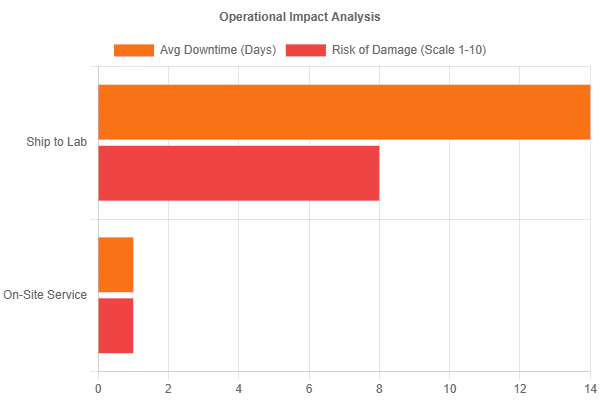

4. Why On-Site High Voltage Calibration Wins

Shipping 200lb equipment via common carriers often leads to damaged meters or cracked casings.

On-site calibration eliminates shipping risks and drastically reduces downtime.

✔ Zero Downtime

Equipment stays on the job site. Calibration is performed in hours, not weeks.

✔ Risk Mitigation

No shipping means zero risk of freight damage to sensitive high-voltage transformers.

✔ Real-World Context

Calibrating in the actual working environment accounts for local factors.

In the United States, logistics can be a nightmare for heavy equipment. A standard AC Test Set can weigh anywhere from 50 to 200 pounds (or more for trailer-mounted systems). Shipping these units to a lab via common carriers often leads to damaged meters or cracked casings.

This is why On-site High Voltage Calibration has become the preferred choice for major utilities and electrical contractors.

Benefits of Field Calibration:

-

Zero Downtime: Your equipment stays on the job site. The calibration is performed in hours, not weeks.

-

Risk Mitigation: No shipping means no risk of freight damage to sensitive high-voltage transformers.

-

Real-World Conditions: Calibrating the unit in its actual working environment ensures that local factors are accounted for.

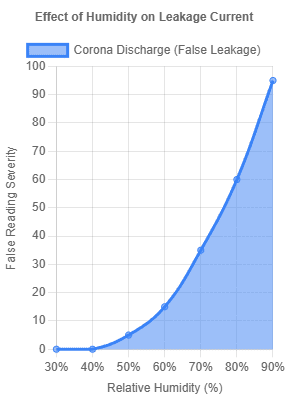

5. The Environmental Factor: Impact on High Voltage Accuracy

The Environmental Factor

High-voltage measurements are sensitive to the air around them. A standard “office” lab ignores these variables, but field calibration accounts for them.

- Humidity: Can cause “Corona Discharge,” mimicking leakage current.

- Altitude: Lowers dielectric strength of air, affecting spark-over distance.

- Temperature: Extreme heat causes internal shunt resistance drift.

Impact of Humidity on Leakage Readings (Uncorrected)

High-voltage measurements are sensitive to the air around them. Professional calibration technicians must account for environmental variables that a standard “office” lab might ignore:

-

Humidity: High humidity can cause “Corona Discharge” around the test leads, which might be misinterpreted as leakage current.

-

Atmospheric Pressure: In high-altitude regions (like Denver, CO), the dielectric strength of air decreases. This can affect the spark-over distance of your test set.

-

Temperature: Extreme heat in field conditions can cause the resistance of internal shunts to drift.

During our On-site High Voltage Calibration, we record these ambient conditions to provide a corrected, accurate certificate of calibration.

6. Compliance: NIST Traceability and ISO/IEC 17025

For most U.S. companies, a calibration certificate is a legal document used for audits by OSHA or NETA.

-

NIST Traceability: This ensures that the standards we use to calibrate your AC Test Set are themselves calibrated by the National Institute of Standards and Technology. It creates an unbroken chain of accuracy.

-

ISO/IEC 17025 Accreditation: This is the international “gold standard” for testing and calibration laboratories. It proves that the lab has the technical competence to produce valid results.

| Feature | Standard Calibration | ISO 17025 Accredited Calibration |

| NIST Traceable | Yes | Yes |

| Measurement Uncertainty Data | No | Yes |

| Accreditation Logo on Cert | No | Yes |

| Best For | Internal reference only | Utility Audits, NETA Compliance, Litigation |

7. Conclusion

An uncalibrated AC Dielectric Test Set is a liability. It can lead to dangerous equipment failures if a defect is missed, or costly delays if a “false fail” occurs. By prioritizing AC Test Set Calibration, particularly through specialized On-site High Voltage Calibration services, you protect your team, your equipment, and your professional reputation.

Don’t Leave Accuracy to Chance

An uncalibrated AC Dielectric Test Set is a liability. Protect your team and reputation with certified accuracy.