Calibration of Particle Counter: The Key to Enhancing Indoor Air Quality (IAQ) and Pathogen Control

In the 21st century, as cities grow and people spend most of their time indoors, the quality of air in these enclosed spaces (IAQ – Indoor Air Quality) has become a critical factor directly impacting health and productivity. In the wake of the COVID-19 pandemic, the public’s awareness of airborne pathogens and particulate matter has fundamentally changed. However, air pollution is an invisible threat. To transform this threat into measurable and manageable data, businesses and organizations must rely on one indispensable tool: the particle counter.

A particle counter helps quantify the concentration of suspended particles in the air. But for these numbers to hold any meaning, the device’s accuracy must be absolute. This is where Calibration of Particle Counter becomes a pivotal step. The calibration process is more than a mere technical procedure; it’s a strategic investment that guarantees safety, regulatory compliance, and operational efficiency in the era of IAQ.

IAQ: From a Concept to a Critical Need

In the past, IAQ was primarily a concern in specialized environments like cleanrooms or laboratories. Today, it has become a widespread issue in all living and working spaces. The indoor environment can be contaminated by various sources, including:

💨 Particulate Matter (PM2.5, PM10)

Sources: Cooking, tobacco smoke, outdoor dust.

🧪 Volatile Organic Compounds (VOCs)

Sources: Paints, furniture, cleaning products.

Impacts: Eye/throat irritation, liver/kidney damage.

🔥 Carbon Monoxide (CO)

Sources: Gas stoves, heaters, portable generators.

Impacts: Headaches, dizziness, potentially fatal.

🍄 Mold & Spores

Sources: Damp environ

The effects of poor IAQ can be severe. Inhaling these pollutants over time can lead to respiratory issues like asthma and bronchitis, as well as cardiovascular diseases. In the long run, it affects overall health and reduces productivity. Therefore, monitoring and controlling IAQ is not just a health issue; it’s an economic one.

Particle Counters: The Indispensable Tool for Measurement and Assessment

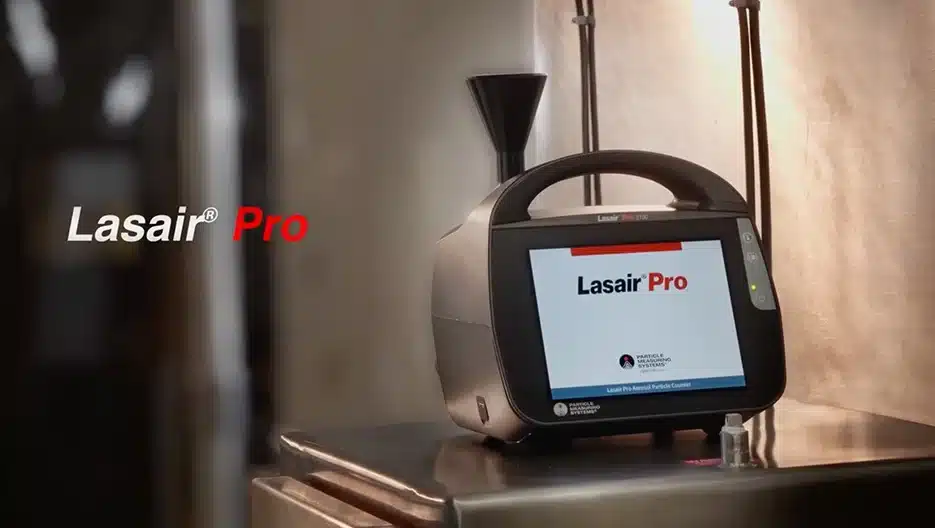

The particle counter is a crucial instrument that turns IAQ from an abstract concept into a manageable dataset. Essentially, the device uses laser technology to illuminate and detect each particle in the air. When a particle passes through the laser beam, the light scatters and is recorded by an optical sensor. Based on the intensity of the scattered light, the device can count and classify particles by size.

Modern particle counters can measure extremely small particles, as tiny as 0.3 micrometers (µm). This is particularly important for pathogen control. Particles measuring 0.5 µm or less are often used to assess air cleanliness because they can remain suspended in the air for extended periods and penetrate deep into the lungs. By providing real-time data, particle counters enable managers to make informed decisions about operating ventilation systems and air filtration.

Why Is Calibration a Decisive Factor?

Data from a particle counter is only valuable when it is accurate. And to ensure that accuracy, calibration is a mandatory requirement. Calibration is the process of comparing your measurement device to a certified standard to ensure it operates within an acceptable range of error.

If a particle counter is not calibrated regularly, its readings can be skewed. An inaccurate measurement can lead to two dangerous scenarios:

- Health Risks: If the particle counter under-reports, the actual number of particles in the air could be much higher than the displayed reading. This poses a serious health risk to people in that space.

- Financial Waste: Conversely, if the device over-reports, it could lead to unnecessary spending on expensive air filtration systems or sanitation measures that aren’t truly needed.

- Non-Compliance: Many industries, especially pharmaceuticals and healthcare, have strict IAQ regulations. Without a calibration certificate, your data is not legally recognized.

Calibration ensures that every measurement is traceable to a national or international standard, providing a solid legal and scientific foundation for all IAQ-related decisions.

Hot-Trend Applications and the Future of IAQ

The calibration of particle counters is not just important for disease control. It has numerous prominent applications in industries that demand high levels of cleanliness:

- Hospitals and Medical Facilities: Ensuring clean air in operating rooms and isolation wards to reduce the risk of cross-contamination.

- Pharmaceutical Manufacturing: Adhering to strict cGMP (Good Manufacturing Practice) standards in cleanrooms to guarantee the safety and efficacy of drugs.

- EV Battery Production Lines: The manufacturing of lithium-ion batteries requires a clean environment to prevent product defects.

- Schools, Offices, and Hotels: Creating a safer and healthier environment for students, employees, and guests, which enhances the overall experience.

In the future, with the rise of the Internet of Things (IoT) and smart building technology, IAQ sensors will become increasingly common. The importance of calibration will grow exponentially. Ensuring these sensors operate with precision will be the key to building truly “smart” buildings that can automatically adjust HVAC systems to protect human health.

Smart Future: AI & IoT Shaping IAQ

The IAQ industry is transitioning from a “reactive” to a “proactive” model, where intelligent systems automatically monitor, analyze, and optimize air quality in real-time.

Smart Sensors

Collect data on PM2.5, CO2, VOCs…

IoT Platforms

Transmit and manage data remotely.

AI Analytics

Learn habits & predict issues.

Automated Systems

Adjust HVAC, air purifiers automatically.

Conclusion: The Importance of Calibration in the IAQ Era

Indoor air quality is no longer a secondary factor. It is a public health issue and a requirement for operational excellence. The particle counter is the indispensable tool for managing this issue. However, the core of this tool’s value lies in its calibration.

Calibrating a particle counter is not just a maintenance step. It’s a commitment to safety, accuracy, and compliance. By ensuring these devices operate with the highest reliability, businesses and organizations can make informed decisions to protect public health, optimize operations, and build a cleaner, safer future.