Pressure measurement is the heartbeat of modern industrial operations. Whether you are managing a sterile cleanroom, maintaining a complex HVAC system, or monitoring gas lines, the accuracy of your instruments is non-negotiable. However, even the most advanced digital manometer is not a “set it and forget it” tool.

In this guide, we dive deep into the technical world of digital manometer calibration, exploring why sensors drift, the professional “exercising” secrets, and how to interpret a NIST-traceable certificate to ensure your operations remain compliant and safe.

Why Do Digital Manometers Lose Accuracy? (Understanding Sensor Drift)

The Silent Killer:

Sensor Drift

A common misconception is that “digital” means immune to wear. In reality, the piezo-resistive sensors inside your device age physically.

Microscopic changes in the silicon or ceramic elements, combined with environmental stressors, cause readings to “drift” over time. It’s an inevitable process that requires regular intervention.

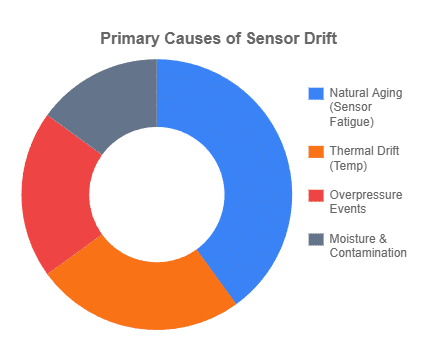

Key Stressors

Thermal Drift: Extreme heat/cold alters electrical resistance.

Overpressure: Permanently deforms the sensing diaphragm.

Contamination: Moisture/Oil degrades internal circuitry.

Figure 1: Estimated Contribution of Factors to Sensor Drift

A common misconception is that because a device is “digital,” it is immune to the mechanical wear-and-tear of analog gauges. In reality, digital pressure gauge calibration is essential because of a phenomenon known as Sensor Drift.

The Science of Drift

At the heart of every digital manometer is a pressure transducer—typically a piezo-resistive or capacitive sensor. Over time, the internal components of these sensors undergo microscopic physical changes. This is “drift.” It is an inevitable aging process of the silicon or ceramic elements within the device.

Environmental Stressors

Beyond natural aging, several factors accelerate the need for digital pressure manometer calibration:

-

Temperature Fluctuations: High heat or extreme cold can alter the electrical resistance of the sensor, leading to “thermal drift.”

-

Overpressure Events: Subjecting a gauge to pressure beyond its rated capacity can permanently deform the sensing diaphragm.

-

Humidity and Contamination: Moisture or oil ingress can degrade the internal circuitry, causing erratic readings.

Pre-Calibration: The Often Overlooked “Exercise” Step

Before a professional technician records a single data point for digital manometer calibration, they perform a critical step that DIY-ers often skip: Exercising the Gauge.

What is “Exercising”?

This involves applying pressure to the device to its full-scale capacity and then venting it back to zero. This cycle is typically repeated three times.

Why It Matters

Think of it as stretching before a marathon. Exercising the gauge:

-

Stabilizes the mechanical stress within the sensor diaphragm.

-

Reduces “memory” effects from previous pressure states.

-

Ensures that the digital differential manometer calibration data is repeatable and consistent.

If your calibration provider doesn’t mention “exercising” or “pre-conditioning,” they might be providing “As-Found” data that doesn’t reflect the true stable state of your instrument.

Step-by-Step Professional Digital Manometer Calibration Procedure

To achieve NIST-traceable results, a laboratory must follow a rigorous, documented process. Here is how a standard digital pressure gauge calibration is executed at an accredited facility:

1. Visual Inspection and Cleaning

Technicians check for cracked casings, clogged ports, and battery health. A dirty port can trap air or moisture, creating false pressure pockets that ruin the calibration.

2. Establishing the Zero Point

The device is vented to the atmosphere to establish a baseline. In digital differential manometer calibration, both ports (P1 and P2) are vented to ensure the differential reading is exactly zero before testing begins.

The Rigorous

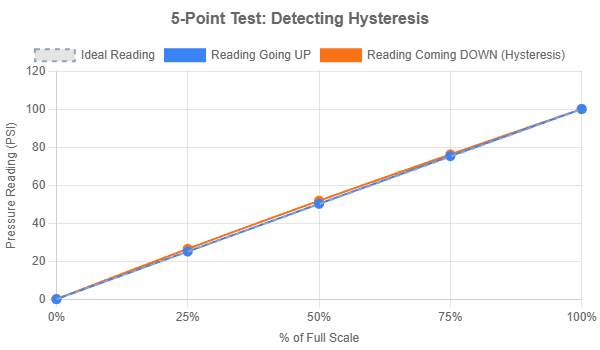

5-Point Test

NIST-traceable calibration isn’t random. It involves comparing the Device Under Test (DUT) against a “Master Gauge” (4x more accurate) at specific intervals:

25%

50%

75%

100%

The Hysteresis Check

Accuracy isn’t just about going up; it’s about coming down.

⚠ Critical Failure Sign: If the reading at 50% is significantly different when “going up” versus “coming down,” the device has a Hysteresis issue, indicating potential sensor damage.

Figure 2: The “Up-Down” Test revealing Hysteresis Error

3. Point-by-Point Comparison (The 5-Point Test)

The device under test (DUT) is connected to a “Master Gauge” or a “Deadweight Tester.” To be valid, the Master Gauge must have a Test Uncertainty Ratio (TUR) of at least 4:1. This means the lab standard is four times more accurate than your device.

The lab tests at least five points across the range: 0%, 25%, 50%, 75%, and 100%.

4. Hysteresis Check: The Up-Down Method

Accuracy isn’t just about going up the scale; it’s about coming back down. Professional digital pressure manometer calibration includes measuring points in descending order. If the reading at 50% is different when “going up” versus “coming down,” the device has a Hysteresis issue, indicating a potential sensor failure.

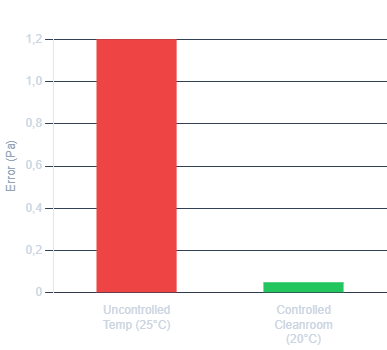

Special Focus: Micromanometer Calibration for Low-Pressure Applications

If you work in pharmaceutical cleanrooms or bio-safety labs, you likely use a Micromanometer. These devices measure incredibly small pressure differences (often < 1 Pascal).

The Cleanroom Challenge: Micromanometers

In pharmaceutical cleanrooms, devices measure pressure differences often less than 1 Pascal. A deviation of just 0.1 Pa can compromise sterile boundaries.

🌡

Strict Temperature Control

High-end labs maintain exactly 20°C (68°F). Air density changes with temp, ruining low-pressure readings.

🤖

Automated Controllers

Hand pumps are too jerky. Automated pressure controllers are required for stable, ultra-low pressure generation.

Figure 3: Impact of 5°C Temp Shift on Low Pressure Readings

The Cleanroom Challenge

In these environments, a deviation of even 0.1 Pa can compromise sterile boundaries. Consequently, Micromanometer calibration requires:

-

Highly Stable Pressure Sources: Standard hand pumps are too jerky; labs must use automated pressure controllers.

-

Controlled Reference Conditions: High-end labs maintain a strict temperature of $20^\circ\text{C}$ ($68^\circ\text{F}$) because air density changes with temperature, which directly affects low-pressure readings.

Decoding Your Calibration Certificate

When you receive your device back from the lab, the Calibration Certificate is your proof of compliance. But do you know what to look for?

NIST Traceability

A NIST-traceable certificate means the accuracy of your digital pressure gauge calibration can be traced back through an unbroken chain of comparisons to the National Institute of Standards and Technology (NIST) in the USA.

“As-Found” vs. “As-Left”

-

As-Found: The accuracy of the device when it first arrived at the lab. This tells you if your previous measurements were “out of tolerance.”

-

As-Left: The accuracy after the lab has performed any electronic adjustments or offsets.

Uncertainty vs. Error

-

Error: The difference between what your gauge says and what the Master Gauge says.

-

Uncertainty: A statistical value representing the “doubt” in the measurement. A professional lab always reports the uncertainty to prove the reliability of the test.

How Often Should You Recalibrate?

While most manufacturers recommend a 12-month cycle for digital manometer calibration, this is not a one-size-fits-all rule. You should consider shorter intervals if:

-

The device is used daily in harsh field conditions.

-

It has suffered a physical drop or impact.

-

The data is used for high-stakes regulatory compliance (FDA, FAA, EPA).

Conclusion: Choosing the Right Calibration Partner

Not all calibration services are created equal. When searching for digital pressure manometer calibration or digital differential manometer calibration providers, prioritize those with ISO/IEC 17025 accreditation. This ensures the lab has been independently audited for technical competence.

Is your accuracy at risk?

Ensure your facility runs at peak performance with NIST-traceable calibration.

Generated based on professional calibration standards. ISO/IEC 17025 Compliant.