Electrical Testers: Essential Tools for Safety and Performance – The Vital Role of Calibration

In every field involving electricity—from residential installation and industrial maintenance to automation system checks—the Electrical Tester is an indispensable tool. It’s more than just a measurement device; it’s a guardian of safety, helping technicians quickly identify electrical issues, diagnose faults, and ensure circuits function correctly. The ability to perform rapid, reliable measurements of voltage, current, and continuity makes this device central to every toolkit. However, the effectiveness and safety of an Electrical Tester depend entirely on its accuracy. Therefore, Electrical Tester Calibration is a mandatory, periodic step. It ensures that every measurement is trustworthy, helps prevent dangerous electrical failures, and maintains system operational performance.

CORE APPLICATIONS

Protecting Human Safety

Detects electrical leakage, short circuits, and insulation failure to prevent electric shock accidents and fires.

Ensuring Installation Quality

Verifies continuity, voltage, frequency, and the operation of protective devices (RCDs, fuses).

Diagnosis & Troubleshooting

Identifies voltage drops, analyzes power quality, and quickly finds the root cause of equipment failures.

1. Diverse Applications of Electrical Testers

The Electrical Tester is designed to perform basic yet critically important electrical measurements in a wide variety of scenarios.

1.1. Ensuring Electrical Safety

This is the primary and most crucial application of any Electrical Tester.

- Power Verification: Before initiating any repair or maintenance, technicians must check for voltage presence at outlets, switches, panels, or conductors. This prevents the risk of severe electric shock.

- Hazard Detection: The device quickly identifies and warns about the presence of AC or DC voltage in a circuit or piece of equipment, ensuring the work area is safe.

1.2. Rapid Electrical Troubleshooting and Diagnosis

The capacity for quick measurement saves time and cost in fault-finding.

- Voltage Checks: Determining input voltage, voltage across a load, or checking for voltage drop in a circuit. This helps diagnose issues like unstable power supply or device failure.

- Non-Contact Current Measurement: Many modern Electrical Testers allow for the measurement of AC current without needing to break the circuit or open the conductor (often using an open-jaw feature). This is extremely useful for:

- Load Testing: Determining the actual current draw of a motor or circuit to detect overloads or inefficient operation.

- Fault Detection: Rapidly checking current to pinpoint problems like a stuck motor or a faulty coil consuming excessive power.

- Continuity Testing: Quickly determining if a wire, fuse, switch, relay, or motor coil is open (broken). An audible beep indicator allows for fast checks without needing to look at the screen.

1.3. Installation and System Commissioning

During installation, the Electrical Tester ensures proper and safe connections.

- Connection Verification: Ensuring conductors are correctly terminated and that there are no faults in new wiring systems.

- Functionality Checks: Confirming that components like switches, receptacles, and lighting are operating as expected after installation.

2. The Vital Role of Electrical Tester Calibration

An Electrical Tester, no matter how good, will lose accuracy over time due to wear, environmental conditions, or continuous use. Therefore, periodic calibration is a mandatory requirement, not just for quality assurance but for safety.

THE CRITICAL ROLE OF CALIBRATION

Preventing Measurement Drift

All equipment loses accuracy over time. Regular calibration helps detect and adjust deviations, ensuring reliable measurement results.

Legal & Standards Compliance

Traceable calibration certificates are legal proof of compliance with safety standards such as ISO/IEC 17025.

Mitigating Accident Risks

An inaccurate measuring device is a potential hazard, capable of leading to incorrect safety assessments and serious accidents.

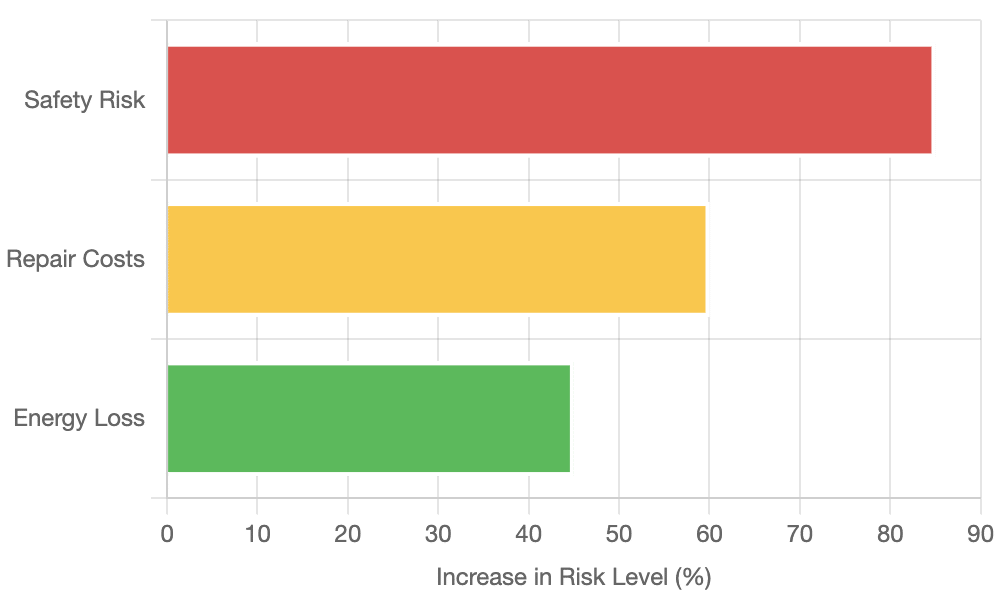

Impact of a 1% Measurement Error

2.1. Ensuring Measurement Accuracy and Reliability

- Compensating for Drift: The internal voltage, current, and resistance sensors can “drift” over time. Calibration adjusts these deviations, ensuring the device displays an accurate value compared to reference standards.

- Checking Linearity and Repeatability: Calibration verifies that the device measures accurately across its entire range (linearity) and provides consistent results when measuring the same value multiple times (repeatability).

- Continuity Function Verification: Even the continuity function must be checked to ensure the resistance threshold for the audible beep is accurate, preventing the overlooking of potential faults.

2.2. Compliance with Safety Standards and Industry Regulations

In many industries, using calibrated measuring equipment is a legal and standard requirement.

- Occupational Safety: Organizations like OSHA (Occupational Safety and Health Administration) mandate that electrical tools be routinely maintained and checked. Calibration is a crucial part of this.

- Quality Standards: Companies adhering to ISO 9001 or specific industry standards must have documented evidence that all their testing and measuring equipment, including Electrical Testers, are periodically calibrated and traceable.

- Product Certification: Measurement results from uncalibrated devices may be rejected during product testing or certification processes.

2.3. Preventing Dangerous Incidents and Saving Costs

- Maximum Safety: An inaccurate Electrical Tester might indicate “no voltage” when voltage is actually present, leading to a potentially fatal electric shock risk. Calibration ensures the device is always reliable.

- Timely Fault Detection: Accurate data from a calibrated device helps technicians diagnose faults more effectively, reducing machine downtime and avoiding unnecessary repairs.

- Extending Equipment Life: Calibration is not just a check; it is part of the maintenance process, helping to detect potential issues with the measuring device itself early on.

MANDATORY CALIBRATION PARAMETERS

| Parameter | Unit | Importance |

|---|---|---|

| Voltage | V | Determines equipment stability, preventing damage from over/under-voltage. |

| Current | A | Error can lead to incorrect protective threshold settings, causing fires/explosions. |

| Resistance | Ω | Crucial for insulation and earth resistance testing, determining the safety level. |

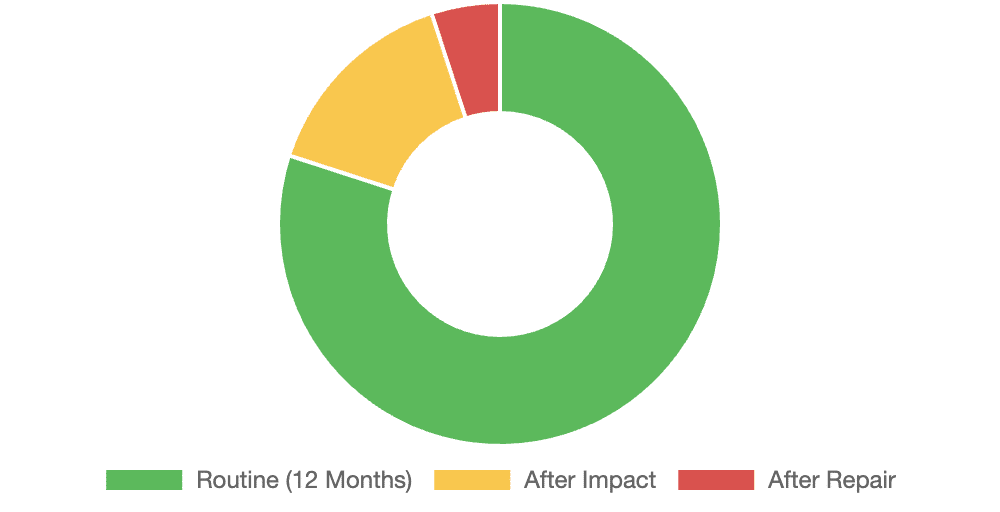

RECOMMENDED CALIBRATION CYCLE

Standard Frequency and Emergency Triggers

Most quality standards (ISO 9001) and manufacturers recommend a routine calibration cycle of 12 months (Annually). This is a mandatory preventative measure against natural equipment drift.

- Routine Calibration: Every 12 months.

- Abnormal Calibration: After device impact, overload, or inconsistent readings.

Incident Classification

Conclusion

The Electrical Tester is a versatile, essential tool, foundational to safety and efficiency in all electrical work. Its ability to quickly and reliably measure voltage, current, and continuity makes it the indispensable partner of every technician.

However, to ensure this tool remains reliable, Electrical Tester Calibration is of utmost importance. It is an investment in safety, quality, and efficiency. It ensures that every decision you make based on a measurement is accurate, helping to protect assets, prevent accidents, and maintain the smooth operation of electrical systems.

Have you checked the last calibration date of the Electrical Tester in your toolbox? Do not let an inaccurate measurement compromise your safety or the quality of your work!