Introduction: Why Insulation Multimeter Calibration Matters

Insulation multimeters, also known as insulation testers or megohmmeters, play a critical role in electrical safety and preventive maintenance. These instruments are used to measure insulation resistance in motors, cables, transformers, and electrical installations, helping engineers detect insulation degradation before it leads to equipment failure or safety hazards.

However, the accuracy of insulation resistance measurements depends heavily on the condition and calibration status of the instrument itself. Without proper insulation multimeter calibration, test results may be misleading, leading to incorrect maintenance decisions, increased downtime, or non-compliance with regulatory requirements.

Calibration ensures that insulation testers provide reliable, traceable, and documented measurement results. It is essential for organizations involved in industrial maintenance, electrical contracting, testing and commissioning, and quality or compliance management.

Insulation Multimeter vs Megohmmeter: Are They the Same?

Definitions

A megohmmeter is a specialized instrument designed specifically to measure high insulation resistance values, typically in the megohm (MΩ) to gigohm (GΩ) range, using high DC test voltages such as 250 V, 500 V, or 1000 V.

An insulation multimeter is a more versatile device that combines standard multimeter functions (voltage, current, continuity) with insulation resistance testing capability.

Key Differences

While a megohmmeter focuses solely on insulation testing, an insulation multimeter offers additional measurement functions. In practice, both instruments perform insulation resistance measurements using similar principles and test voltages.

Terminology in Calibration Services

In calibration and metrology contexts, the terms insulation multimeter calibration and insulation tester calibration are often used interchangeably. Including both terms in technical documentation and service descriptions improves clarity for users and ensures alignment with common search intent.

What Is Insulation Multimeter Calibration?

Insulation multimeter calibration is the process of comparing the measurement results of an insulation tester against known reference standards with documented accuracy. The goal is to determine whether the instrument’s readings fall within specified tolerances.

It is important to distinguish between:

-

Calibration: Measurement comparison and documentation

-

Adjustment: Mechanical or electronic correction of the instrument

-

Verification: Confirmation that results meet predefined criteria

Calibration does not automatically involve adjustment or repair. Instead, it provides objective evidence of measurement performance at the time of testing.

The Cost of Inaccuracy

Insulation multimeters operate in high-energy environments. When they drift, they don’t just give wrong readings; they expose technicians to arc flash risks and facilities to fire hazards.

Standard Interval

The recommended calibration cycle for most insulation testers to ensure compliance with ISO 9001 and safety standards.

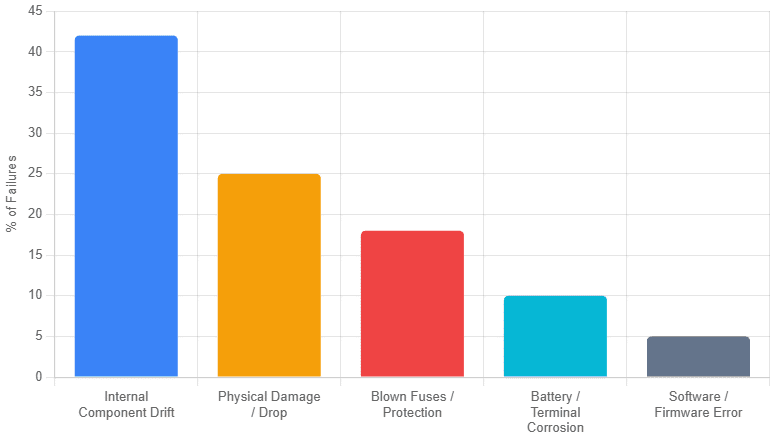

OOT Rate

Percentage of field instruments found “Out of Tolerance” (OOT) upon annual receipt, requiring significant adjustment.

High Resistance

Measuring gigohms requires precision voltage generation (e.g., 1000V). Small internal voltage drifts cause massive reading errors.

Calibration Standards and Traceability

Applicable Standards

Professional insulation tester calibration is typically performed in accordance with internationally recognized standards, including:

-

ISO/IEC 17025 for calibration laboratory competence

-

Relevant IEC standards related to insulation resistance measurement

Calibration conducted under these frameworks ensures technical validity and audit readiness.

Measurement Traceability

Traceability refers to an unbroken chain of comparisons linking measurement results to national or international standards. This ensures consistency and reliability across laboratories, instruments, and time.

For insulation multimeter calibration, traceability is established using certified reference standards such as high-value resistors and calibrated voltage sources.

Calibration Certificate Content

A proper calibration certificate should include:

-

Instrument identification details

-

Environmental conditions during calibration

-

Reference standards used

-

As-found and as-left measurement results

-

Measurement uncertainty

These elements are essential for quality systems, audits, and compliance documentation.

The Calibration Workflow

A professional calibration is more than just checking a number. It is a rigorous 5-step process ensuring the instrument performs safely across its entire range.

Cleaning & Inspection

Check for terminal corrosion, cracks, or battery leaks.

Battery & Fuse Check

Ensure power stability and safety fuse continuity.

Functional Test

Verify display segments, buttons, and buzzer logic.

Accuracy Verification

Compare against Standards at 25%, 50%, 75%, 100% range.

Certification

Issue traceable certificate with As-Found/As-Left data.

The Danger of “Good Enough”

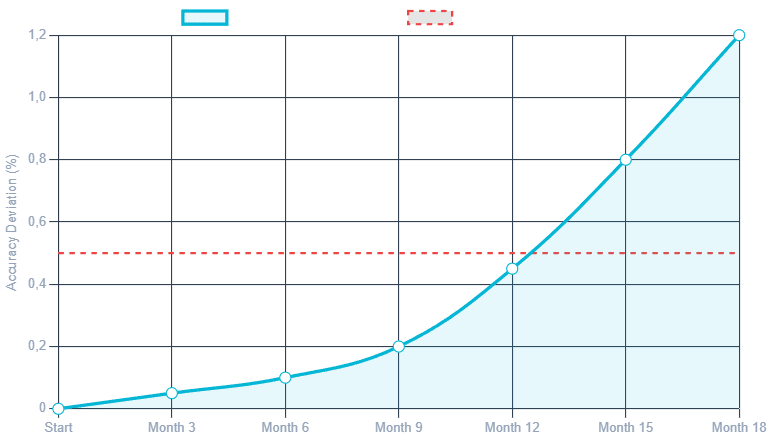

Electronic drift is rarely linear. As shown in the graph, a meter may remain stable for months (Phase A) before environmental factors cause a rapid acceleration in error (Phase B), crossing the tolerance threshold (Phase C).

Phase A: Stability

New components hold value well. Readings are reliable.

Phase B: Accelerated Drift

Temperature cycling and humidity begin to alter resistor tolerances.

Phase C: Out of Tolerance

The meter reads “Pass” on a dangerous circuit. Safety is compromised.

Calibration Interval: How Often Should You Calibrate?

A typical recommended calibration interval for insulation multimeters is 12 months, unless otherwise specified by the manufacturer or regulatory requirements.

Factors that may require shorter intervals include:

-

Frequent or intensive use

-

Harsh environmental conditions

-

Critical safety applications

-

Internal quality management policies

Regular calibration helps prevent measurement drift and reduces the risk of undetected insulation faults.

Safety Considerations During Insulation Testing and Calibration

Insulation testing involves high DC voltages, which can pose safety risks if not properly controlled. Key considerations include:

-

Ensuring circuits are de-energized before testing

-

Discharging capacitive components after testing

-

Using appropriate personal protective equipment

-

Performing calibration in controlled laboratory conditions

Safety-focused calibration practices protect both personnel and equipment.

Common Applications of Insulation Multimeter Calibration

Insulation tester calibration is widely used in:

-

Electric motor maintenance

-

Power cable and wiring system testing

-

Transformer insulation assessment

-

Switchgear and control panel inspection

-

Industrial equipment commissioning and maintenance

Accurate insulation resistance data supports informed maintenance decisions and long-term asset reliability.

Common Mistakes and Misconceptions

Common misunderstandings include:

-

Assuming calibration is unnecessary if the instrument “still works”

-

Confusing functional checks with formal calibration

-

Ignoring measurement uncertainty values

-

Using incorrect test voltages for specific applications

Addressing these misconceptions improves measurement integrity and safety outcomes.

The Chain of Trust: NIST Traceability

Your calibration certificate is only as valid as the standards used to test it. This hierarchy ensures your 1GΩ reading matches the national standard.

SI Units / NIST

National Institute of Standards & Technology

Primary Standards

High-precision commercial labs

Working Standards

The calibrator used on your meter (e.g., Fluke 5500A)

Process Instrument

Your Insulation Multimeter

FAQs – Insulation Multimeter Calibration

Is insulation tester calibration the same as megohmmeter calibration?

Yes. In practice, both terms refer to calibration of instruments used for insulation resistance measurement.

Can insulation multimeter calibration be performed onsite?

Some calibrations can be performed onsite, but laboratory calibration offers better environmental control and lower uncertainty.

What happens if an instrument fails calibration?

The results are documented, and adjustment or repair may be recommended before re-calibration.

Does calibration improve accuracy?

Calibration itself does not change accuracy but confirms and documents measurement performance.

Techmaster’s Insulation Multimeter Calibration Capability

Techmaster provides professional insulation multimeter calibration services for industrial and laboratory applications. Our capabilities include:

-

Calibration performed in accordance with ISO/IEC 17025 principles

-

Traceable reference standards

-

Detailed calibration certificates with uncertainty reporting

-

Support for insulation testers, megohmmeters, and multifunction electrical instruments

With experienced metrology engineers and controlled calibration environments, Techmaster helps customers maintain accurate measurements, regulatory compliance, and operational confidence.

Conclusion

Insulation multimeter calibration is a critical component of electrical safety, preventive maintenance, and quality assurance. By ensuring accurate, traceable, and documented measurements, organizations can reduce risk, improve reliability, and meet compliance requirements.

Regular insulation tester calibration should be an integral part of any electrical testing and maintenance program.