Pocket Laser Tachometer: The Essential Tool for Machine Performance Analysis – The Role of Accurate Calibration

In industrial predictive maintenance and quality control, rotational speed is a fundamental yet crucial detail. The Pocket Laser Tachometer offers an ideal way to measure the rotational speed of motors, fans, pumps, or conveyors without touching them. This device uses laser reflection principles to precisely determine Revolutions Per Minute (RPM). Ultimately, accurate RPM data forms the basis for judging equipment performance, lifespan, and safety. Consequently, Laser Tachometer Calibration is a necessary process. It ensures that the RPM data obtained is reliable. This, in turn, helps technicians make better maintenance decisions, preventing costly and dangerous machine failures.

1. What is a Laser Tachometer?

A laser tachometer is a non-contact device that measures the rotational speed (RPM) of a spinning object by using a laser beam to count the number of rotations per minute. A small strip of reflective tape is typically placed on the rotating object, and the tachometer measures the pulses of light reflected back from the tape to determine the speed. This allows for accurate, contactless measurements in a wide variety of applications, including motors, fans, and machinery.

1.1. How it Works:

- Laser Emission: The device emits a visible laser beam.

- Reflective Tape: A technician attaches a small piece of reflective tape (often silver or white) to the rotating shaft, gear, or target object.

- Signal Reception: As the shaft spins, the laser beam hits the reflective spot and bounces back to the device’s optical sensor. When the spot moves away, the reflected signal is lost, creating a series of light pulses.

- RPM Calculation: An internal microprocessor counts how many times the sensor receives a reflected pulse within a specific timeframe (period). The device then calculates Revolutions Per Minute (RPM) using the formula: .

1.2. Key Advantages:

- Non-Contact: This allows for safe measurement from a distance, minimizing operator risk.

- High Accuracy: Using discrete light signals (laser pulses) helps the device achieve high accuracy across a wide speed range.

- Versatile: It is ideal for measuring rotating machine parts in hard-to-reach or hazardous areas.

2. Core Applications of the Laser Tachometer

The Laser Tachometer is a crucial tool in industrial maintenance, quality control, and research.

Predictive Maintenance

Early detection of speed deviations—signs of bearing wear or imbalance.

Quality Control

Ensuring machinery operates at the correct design speed (conveyors, centrifuges).

Vibration Analysis

Provides the foundational RPM to accurately determine fault vibration frequencies.

Frequency Tuning

Fine-tuning motor speed, optimizing energy efficiency, avoiding resonance.

2.1. Predictive Maintenance and Vibration Analysis 🛠️

This is its most important use in asset care:

- Nameplate RPM Verification: Technicians verify that the machine’s real speed matches its design speed. Indeed, wrong RPM can point to power issues, too much load, or machine wear.

- Vibration Analysis: RPM data is key input for vibration analysis gear. To explain, accurate RPM data lets technicians find the source of vibration (e.g., balance issues, misalignment). They do this by linking vibration frequency to the spin rate.

- Motor Fault Diagnosis: Tracking RPM changes over time helps find early problems like slipping belts or gearbox faults.

2.2. Manufacturing Quality Control (QC)

- Conveyor Speed Measurement: It measures the RPM of rollers to figure out the belt’s linear speed. This is vital for keeping production times correct and ensuring good product quality.

- Printer/Roller Speed Check: It verifies the speed of printing or laminating rollers. If the speed is off, it leads to poor print quality or wrong product thickness.

2.3. Specialized Applications

- Fan and Blower Speed Measurement: It checks the RPM of fans, ensuring airflow meets cooling needs.

- Standard Speed Signal Generation: Furthermore, some advanced tachometers can save or share speed data. They use the real RPM as a reference point for other monitoring devices.

3. Advantages of Non-Contact Laser Measurement

Using a laser offers big benefits over contact tachometers.

- Safety and Convenience: Technicians measure RPM from a safe spot. This keeps them away from spinning parts.

- No Load Interference: Since this method doesn’t touch the machine, it adds no drag. Therefore, it doesn’t change the machine’s actual speed.

- Ease of Use: Users just stick on a small reflective tape, point the laser, and read the number right away.

4. The Vital Role of Laser Tachometer Calibration

RPM data drives maintenance and quality choices. If the tachometer is wrong, the whole process fails.

4.1. Ensuring Data Integrity for Analysis

- Vibration Accuracy: In vibration checks, small RPM errors cause big mistakes in finding vibration issues. This often leads technicians to guess the wrong fault.

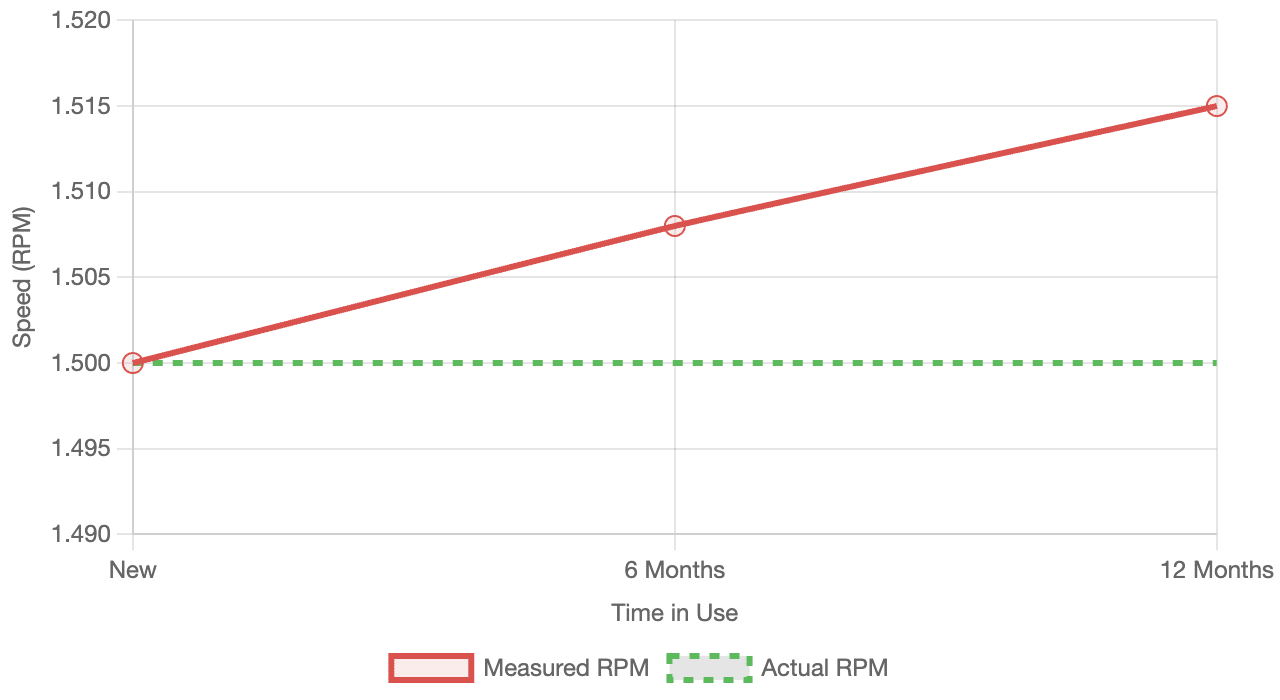

- Preventing Drift: Over time, the internal electronic parts of the tachometer can drift. Periodic calibration fixes this drift. It verifies the device’s accuracy against a known frequency standard.

4.2. Compliance with Standards and Legal Accountability

- Industry Regulation Compliance: Many industry rules demand accurate RPM records. Using a calibrated tachometer provides clear proof of quality and safety compliance.

- Preventing Equipment Damage: An uncalibrated tachometer might report a safe speed incorrectly. This could cause the machine to run too fast or too slow, which harms the equipment.

The Critical Role of Calibration

An uncalibrated measuring device is a massive risk factor. Small RPM errors can lead to erroneous maintenance decisions and huge costs.

RPM Reading Drift

Accumulated error after 12 months without calibration.

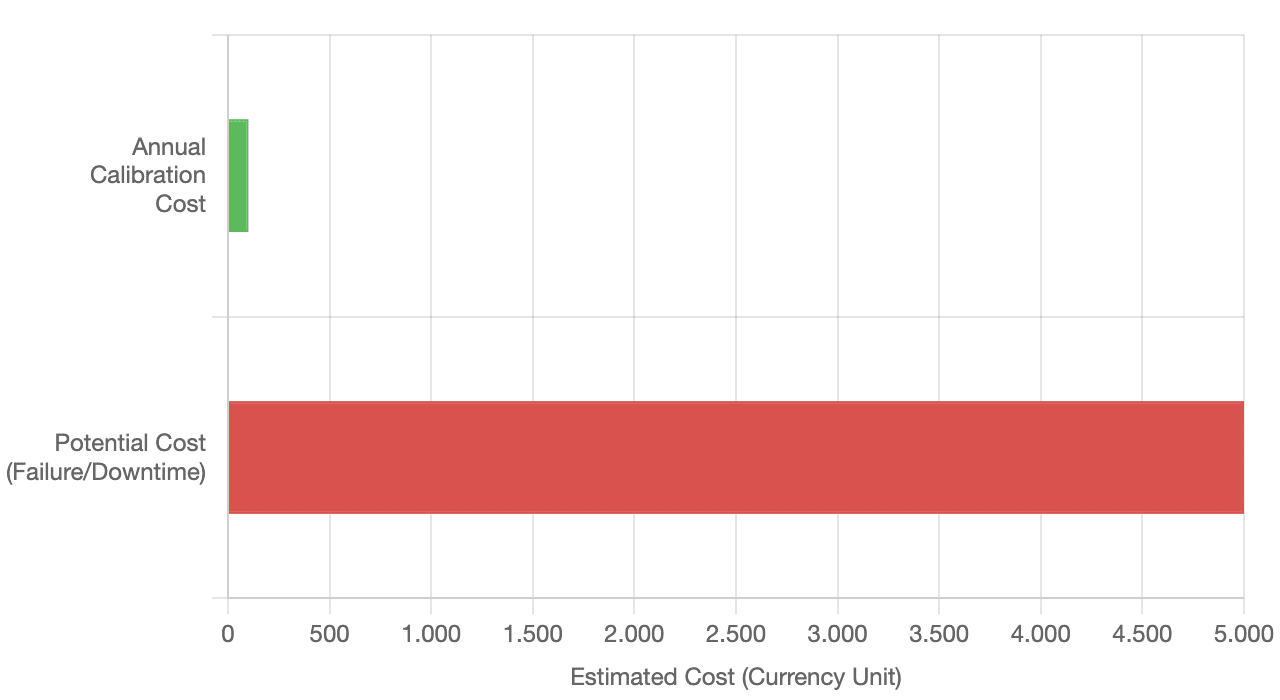

The Cost of Inaccuracy

Comparing the cost of routine calibration vs. fault misdiagnosis.

Why Calibrate & The Process

Combatting Drift

Compensating for the aging of the laser and electronic circuits over time.

Ensuring Traceability

Compliance with ISO 9001, linking measurements to national standards.

Ensuring Safety

Accurate detection of dangerous overspeed conditions.

5-Step Calibration Process

CALIBRATION: INVESTMENT FOR THE FUTURE

Conclusion

The Pocket Laser Tachometer is a key diagnostic tool. It provides accurate, safe, and fast RPM data. Ultimately, the ability to determine exact spin speed is the foundation of good predictive maintenance. Pocket Laser Tachometer Calibration is an investment in data truth. It represents a commitment to safety and protecting all your industrial machinery.