Paperless Recorders: Digital Monitoring Systems and the Vital Role of Paperless Recorder Calibration

In the era of Industry 4.0, manual data logging with paper and pens has become obsolete. Paperless Recorders have transformed the way industrial data is captured, monitored, and stored, replacing traditional chart recorders with intuitive digital interfaces and secure electronic records. These systems enable real-time visibility, long-term data integrity, and seamless compliance with modern industrial standards. However, even the most advanced technology is only as valuable as the accuracy of the data it produces. Over time, sensors and measurement channels can drift, introducing hidden errors that compromise product quality, process stability, and regulatory compliance. This is where Paperless Recorder Calibration becomes essential. Proper calibration ensures that recorded data truly reflects real-world conditions, providing engineers and operators with confidence in every decision they make. By maintaining accuracy and traceability, calibration protects production processes, safeguards quality, and supports reliable, data-driven manufacturing.

1. What is a Paperless Recorder?

What is a Paperless Recorder?

A paperless recorder is an electronic device that replaces traditional chart recorders.

It measures, displays, and securely stores process signals such as temperature,

pressure, and flow in digital memory.

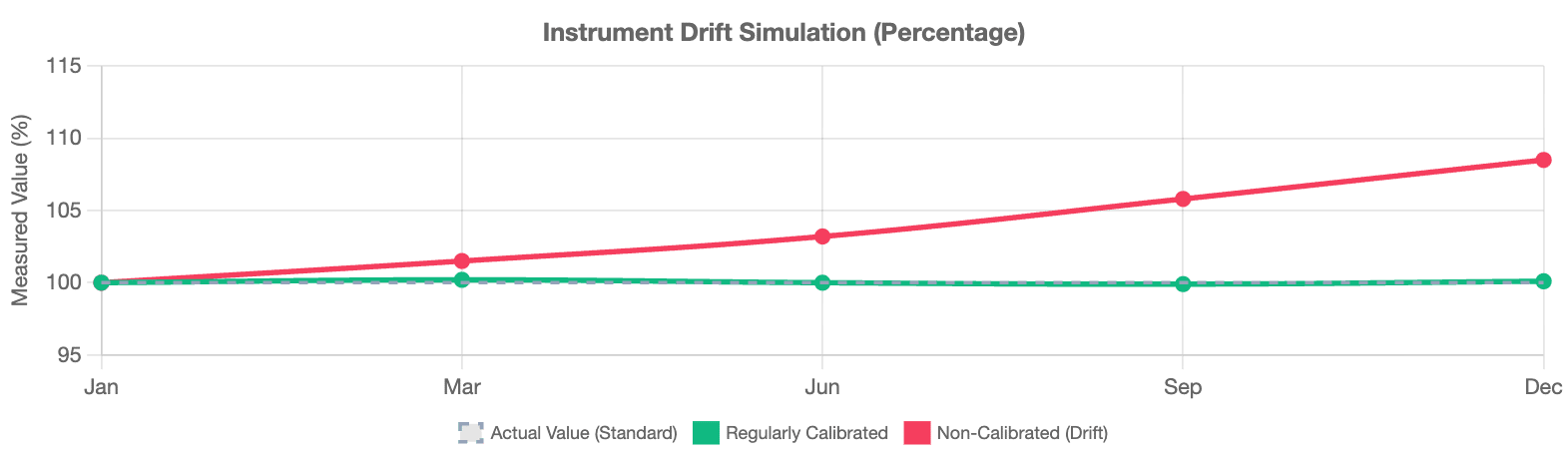

The strength of these devices lies in their network connectivity (Ethernet/RS485). This allows for remote monitoring via a web browser. However, the “heart” of the recorder is the Analog-to-Digital (A/D) converter. Over time, these electronic components can “drift” due to temperature fluctuations or aging. This leads to inaccurate readings. The process of Paperless Recorder Calibration helps verify and correct these errors.

2. Break-through Applications of Paperless Recorders

💊

Pharmaceutical

🌡︎

Heat Treatment

🏭︎

Food & Beverage (HACCP)

🔋

Energy & Utilities

The paperless recorder currently serves as the most important data “hub” in the modern factory.

2.1. Pharmaceutical Industry and FDA 21 CFR Part 11

In drug manufacturing, all temperature and humidity data must be recorded in an unalterable format. Paperless recorders help businesses comply with strict FDA regulations. Regular Paperless Recorder Calibration ensures that the recorded data serves as valid proof of the quality of every medicinal batch.

2.2. Heat Treatment and Metallurgy

Industrial furnaces require extremely precise temperature control. The data recorder monitors heat cycles in real-time. A tiny measurement error can change the physical structure of the metal. Calibrating the device ensures the furnace always operates according to the desired thermal profile.

2.3. Food and Beverage Industry (HACCP)

In pasteurization, time and temperature are the two factors that determine food safety. Paperless recorders track these critical control points. Calibration prevents the risk of mass product spoilage caused by a recorder measuring the temperature incorrectly.

2.4. Energy Management and Power Stations

These devices monitor power consumption, current, and voltage in large electrical systems. Data from the recorder helps engineers optimize operating costs. It also allows for the early detection of anomalies within the power grid.

3. Why is Paperless Recorder Calibration Critical?

Drift Prevention

Electronic components naturally drift over time, affecting measurement accuracy.

FDA / ISO Compliance

Mandatory for pharmaceutical, food, and regulated industries (GMP, HACCP).

Data Integrity

Ensures reliable and traceable records for every production batch.

Many believe that digital devices never fail or drift. In reality, Paperless Recorder Calibration is a mandatory requirement for several reasons:

-

Ensuring Data Integrity: Inaccurate data leads to wrong production decisions. Calibration ensures that the numbers on the screen reflect reality.

-

Multi-channel Accuracy: Recorders often have 6 to 48 input channels. Each channel can drift differently. Calibration synchronizes all measurement channels.

-

Compliance with Quality Audits: Standards like ISO 9001 or IATF 16949 require data recording devices to have valid calibration certificates.

-

Compensating for System Errors: Calibration does not just check the recorder. it identifies errors when combined with sensors (like Thermocouples or RTDs). This optimizes the entire measurement chain.

4. The Professional Calibration Procedure

Modern Calibration Workflow

A standard Paperless Recorder Calibration procedure involves several rigorous steps:

-

Visual and Configuration Check: Technicians confirm all channels are functioning. They also ensure the touchscreen has no “dead” pixels.

-

Input Signal Simulation: A technician uses a multi-function calibrator to send precise voltage, current, or resistance (RTD) signals into each channel.

-

Multi-point Testing: The lab tests the device at at least 3 to 5 points (e.g., 0%, 50%, and 100% of the range). This verifies the linearity of the signal converter.

-

Real-time Clock (RTC) Verification: Technicians ensure the recorder’s clock matches international standard time. This is vital for accurate data time-stamping.

-

Issuing the Calibration Report: All errors found before and after adjustment are documented. This includes the measurement uncertainty for each reading.

5. Maintenance Tips to Preserve Accuracy After Calibration

After completing your Paperless Recorder Calibration, follow these best practices:

-

Regular Data Backups: Even with large internal memory, you should set up automatic data transfers to a server or cloud storage.

-

Inspect Connections: Loose or oxidized signal wires can create electrical noise. This causes inaccurate logs even if the device itself is well-calibrated.

-

Update Firmware: Manufacturers often release updates to fix software bugs. These updates can improve signal processing algorithms.

-

Optimize Installation Environment: Avoid installing recorders near strong electromagnetic interference sources, such as large motors or inverters.

Conclusion

The paperless recorder is the digital diary of every modern factory, capturing critical process data that defines product quality, operational efficiency, and compliance. However, a diary only has value when it records the truth. Even minor measurement drift, if left unchecked, can gradually undermine process control, lead to costly production losses, or expose your operation to regulatory and reputational risks. Investing in periodic Paperless Recorder Calibration is not merely a technical requirement—it is a strategic safeguard for your production line and your brand’s credibility. Accurate, traceable data empowers engineers to make confident decisions and ensures that every recorded value can be trusted. Do not allow small recording errors to escalate into large-scale disruptions. Calibration is the final assurance that your data, your processes, and your reputation remain fully protected.