Process Calibrators are essential tools used to verify, simulate, and measure common industrial signals such as 4–20 mA, voltage, resistance (RTD), thermocouple signals, pressure, and frequency. They play a critical role in ensuring that transmitters, sensors, controllers, and PLC I/O systems operate within the accuracy and safety requirements of a process plant. Regular process calibrator calibration is important to maintain their accuracy and reliability.

In manufacturing, pharmaceuticals, food & beverage, oil & gas, and utilities, even a small measurement deviation can lead to downtime, energy waste, compliance violations, or product quality issues. That’s why process calibrator calibration is a foundational activity for any plant maintenance or instrumentation team.

To help readers understand the market and choose the right device, below are the three most common types of Process Calibrators.

Types of Process Calibrators

Standard Process Calibrators

These are the most frequently used devices for everyday field work.

Features:

-

Measure & source mA, V, RTD, TC

-

Loop power (24 V)

-

Adequate accuracy for most maintenance tasks

-

Manual documentation

Great for technicians who need a reliable, rugged tool for daily troubleshooting.

Precision Process Calibrators

Designed for applications where tight tolerances and high stability are required, often in calibration labs or metrology departments.

Features:

-

Higher accuracy & resolution

-

Stable reference performance

-

Ideal for calibrating other calibrators or critical instruments

Documenting Process Calibrators

These advanced models automate the logging and storing of calibration results, helping technicians manage compliance-heavy tasks more efficiently.

Features:

-

Automated As-Found / As-Left data capture

-

Pass/Fail assessment

-

Integration with calibration software

-

Reduced human error and faster reporting

What Is Calibration & Why It Matters

Calibration is the process of comparing an instrument’s measured values with a known reference standard to determine whether it is within acceptable tolerance. If deviations are found, adjustment or correction may be required.

Why calibration is essential:

-

Ensures measurement reliability

-

Maintains product quality

-

Prevents process drift and equipment damage

-

Supports ISO/IEC 17025, ISO 9001, GMP, and regulatory audits

-

Minimizes downtime due to faulty readings

In industrial environments, consistent calibration directly affects safety, efficiency, and operational stability.

When & Why You Should Calibrate a Process Calibrator

A Process Calibrator itself is a measurement instrument—and like any instrument, it can drift over time due to normal wear, aging components, or harsh operating conditions.

You should perform process calibrator calibration when:

-

The device is new

-

After repair or heavy physical impact

-

At regular intervals (typically 12 months, depending on usage)

-

Before critical measurement work

-

When drift is suspected

-

During audits or quality assessments

Skipping calibration can lead to cascading measurement errors across an entire process system.

ISO 17025

ANSI/NCSL Z540

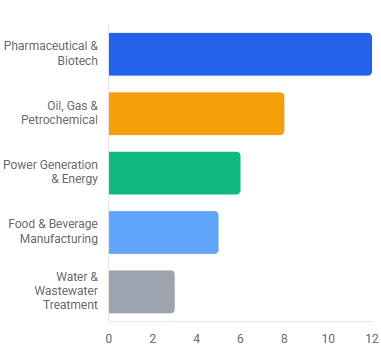

Critical Demand by Sector

In the United States, regulatory compliance (FDA, EPA, OSHA) drives the need for rigorous process calibration.

While manufacturing forms the backbone, the Pharmaceutical and

Oil & Gas sectors demand the highest frequency of calibration due to the direct impact on safety and product efficacy.

Projected US Market Growth (2025)

+5.4%

Source: Aggregated Industrial Maintenance Reports 2024

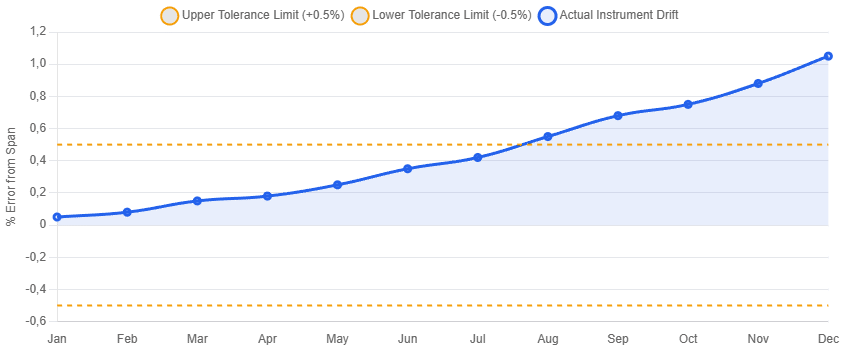

The Silent Killer: Instrument Drift

Every process calibrator loses accuracy over time. This phenomenon, known as drift, is inevitable.

Factors such as thermal stress, mechanical shock, and component aging cause the output to shift away from the “True Value.”

Restoring the Standard

The histogram to the left illustrates the critical impact of professional calibration.

The Red distribution represents an instrument “As Found” (Out of Tolerance),

showing a wide variance and offset mean.

The Green distribution shows the “As Left” state after adjustment.

The data returns to a tight normal distribution centered on the reference standard, ensuring process safety.

The Calibration Workflow

A Standardized 5-Step Loop for US Quality Compliance

Remove device from active process loop to prevent false alarms.

Connect to a NIST-traceable standard 4x more accurate than the DUT.

Record readings at 0%, 50%, and 100% of span before adjustment.

Zero and Span adjustments to bring error within tolerance limits.

Final “As Left” test and generation of Calibration Certificate.

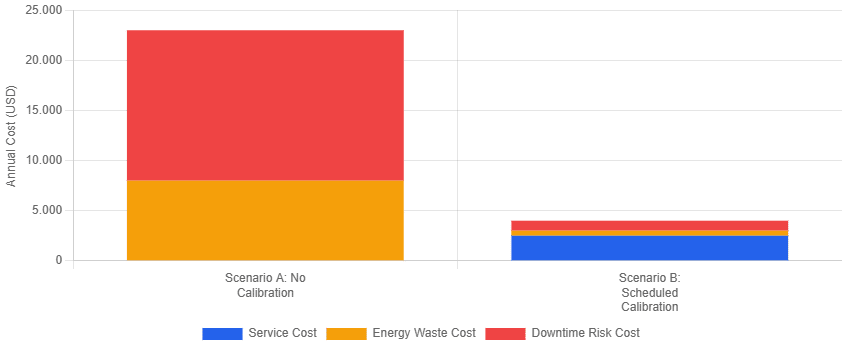

The ROI Equation

Many facility managers hesitate at the upfront cost of calibration services. However, data shows that a single event of

Batch Failure or Unplanned Downtime

can cost 10x to 50x the price of an annual calibration contract.

“Calibration is not a cost; it is an insurance policy against catastrophic process inefficiency.”

Reference Standards & Traceability Requirements

To ensure a trustworthy process calibrator calibration procedure, the reference standard used must have higher accuracy and be traceable to national or international standards (such as VN, NIST, DAkkS, JCSS).

Requirements include:

-

Valid calibration certificate for the reference standard

-

Control of environmental conditions

-

Reliable accessories (leads, probes, connectors)

Environmental conditions that must be controlled:

-

Temperature (commonly 20–26°C)

-

Humidity

-

Vibration and airflow

-

Warm-up time of equipment

Good calibration requires a stable and controlled environment.

Quality Control, Measurement Uncertainty & Accreditation

A high-quality calibration process incorporates:

Measurement Uncertainty

Indicates the confidence level of the measurement.

Critical for regulated industries like pharmaceuticals or energy.

Test Uncertainty Ratio (TUR)

Defines accuracy relationship between reference and instrument under test (IUT).

Common requirement: TUR ≥ 4:1.

ISO/IEC 17025 Accreditation

Ensures that calibration laboratories meet international quality and technical competence standards.

Techmaster’s service ecosystem supports customers with traceable, compliant calibration aligned to modern industrial requirements.

Best Practices & Common Mistakes to Avoid

To maintain measurement integrity:

Best Practices

-

Stabilize environment before calibration

-

Use dedicated, clean connectors and leads

-

Warm up the device properly

-

Follow SOPs for each type of signal

-

Cross-check results when readings look suspicious

Common Mistakes

-

Not recording As-Found data

-

Using non-traceable reference standards

-

Calibrating in unstable temperature conditions

-

Forgetting turbidity induced by poor wiring

-

Ignoring next-due calibration scheduling

Choosing the Right Calibrator: Standard vs Precision vs Documenting

Use this section to support SEO for the related keywords but still keep main article focused:

Standard Process Calibrator

Good for general maintenance and troubleshooting.

Precision Process Calibrator

Ideal for strict accuracy requirements, calibration labs, and QA.

Documenting Calibrator

Best for compliance-heavy environments needing automated reporting.

By understanding the differences, maintenance managers can avoid overspending and select the right device for their workflow.

Frequently Asked Questions (FAQ)

How often should a Process Calibrator be calibrated?

Typically every 12 months, unless used in harsh conditions or critical applications.

What happens if a calibrator is out of tolerance?

Adjustment or repair may be required. As-Found data should still be documented.

Can Process Calibrators be calibrated on-site?

Yes. Many calibrations, especially mA/V/TC/RTD, can be done using portable reference standards.

What is the difference between calibration and verification?

Verification checks performance without adjustment, while calibration compares and adjusts if necessary.

Techmaster’s Capabilities in Process Calibrator Calibration

Techmaster is a trusted calibration and metrology partner for industrial manufacturers across Vietnam. With a robust calibration ecosystem and ISO/IEC 17025-compliant processes, Techmaster provides:

-

Calibration for all major Process Calibrator brands (Fluke, Beamex, Additel…)

-

Traceable reference standards ensuring accuracy and reliability

-

On-site and in-lab calibration services

-

Accurate measurement uncertainty evaluation

-

Fast lead time & transparent documentation

-

Support for As-Found / As-Left procedures and audit requirements

Our mission is to help factories maintain accurate, safe, and compliant measurement systems—reducing downtime and improving long-term reliability.

Conclusion

Process Calibrator calibration is essential for ensuring the accuracy and reliability of your industrial measurement systems. By following a structured calibration workflow, controlling environmental conditions, and using proper reference standards, technicians can maintain high measurement integrity across the entire plant.

For companies seeking accurate, reliable, and traceable calibration, Techmaster provides industry-leading services with a strong focus on compliance, data integrity, and fast turnaround.