Radiometers: The Decisive Tool for Non-Destructive Testing (NDT) Quality – The Vital Role of Calibration

In many high-stakes industries that demand stringent safety and quality standards, surface material inspection via Non-Destructive Testing (NDT) techniques is mandatory. One of the key tools supporting this process is the Radiometer, also known as a Light Intensity Meter. This device precisely measures the intensity of radiation (typically UV light and visible light) used to activate fluorescent inspection materials. Especially, in methods like Magnetic Particle Testing (MT) and Liquid Penetrant Testing (PT), UV intensity and ambient brightness dictate the ability to detect defects. Therefore, Radiometer Calibration is not just a technical procedure; it is a compulsory requirement to ensure safety, quality, and compliance with strict international standards.

1. What is a Radiometer? Understanding the Light Intensity Meter

A Radiometer is an optical instrument specifically designed to measure the radiant power (or radiant flux) of electromagnetic radiation. In practical terms, for industrial and NDT applications, it measures the intensity of light—specifically ultraviolet (UV) radiation and visible light (illumination)—at a given point.

1.1. Key Characteristics:

- Spectral Response: Unlike generic light meters, a radiometer is typically designed with a specific spectral response, meaning it measures light within a defined range of wavelengths. For NDT, this usually involves UV-A (315-400 nm, peaking at ~365 nm) and visible light (400-760 nm).

- Units of Measurement:

- UV Intensity: Measured in microwatts per square centimeter () or milliwatts per square centimeter (). This quantifies the amount of UV radiant power falling on a surface area.

- Visible Light (Illumination/Luminance): Measured in foot-candles () or lux (). This quantifies the perceived brightness of light.

- Components: A typical radiometer consists of a sensor head (containing a photodetector and optical filters to select specific wavelengths), a display unit, and often data logging capabilities.

1.2. Why is it Different from a Photometer or UV Meter?

While a Radiometer can perform similar functions, in the NDT context, it specifically refers to a dual-function meter capable of accurately measuring both the UV-A radiation (crucial for fluorescent indications) and visible light (for background light control) using specialized sensors and filters to meet stringent industry standards.

Radiometer vs. Photometer / UV Meter

While all measure light, the Radiometer is distinct due to its focus on Irradiance (power per area) within a

specific, narrow spectral band, crucial for precise dosage control.

Radiometer

Measures: Irradiance (W/cm²)

Spectral Response: Narrow Band (e.g., UV-A only, 365nm)

Primary Use: Dosage Control (Curing, Medical)

Photometer

Measures: Illuminance (Lux/Foot-candle)

Spectral Response: Visible Light (400–700nm)

Primary Use: Human Perception (Lighting)

UV Meter

Measures: General UV Power

Spectral Response: Broad Band (e.g., UV-A + UV-B)

Primary Use: General Monitoring (Safety, Environmental)

Applications

Solar Energy

Measures solar irradiance to evaluate and optimize the performance and output efficiency of photovoltaic systems.

Medical & Dermatology

Precisely controls the UV dosage during phototherapy for safe and effective treatment of skin conditions.

Manufacturing & UV Curing

Ensures UV intensity is sufficient for complete curing of inks, coatings, and adhesives — critical for product quality and durability.

UV-C Sterilization

Verifies the efficacy of UV-C lamps in killing microorganisms in hospitals, labs, and the food & beverage industry.

2. Core Applications of the Radiometer

The Radiometer is an indispensable instrument in environments that require controlled light intensity to guarantee process quality.

2.1. Non-Destructive Testing (NDT) – Fluorescent Methods

This represents the most critical industrial application for Radiometers, particularly those measuring both UV and visible light.

- Fluorescent Magnetic Particle Testing (Fluorescent MT):

- Function: It measures the intensity of ultraviolet (UVA, typically around 365 nm) radiation illuminating the material surface. The UV light activates fluorescent magnetic particles to glow, highlighting microscopic cracks and defects on ferromagnetic materials.

- Importance: Industry standards (such as ASTM E3022) mandate a minimum UV intensity threshold (e.g., ) to ensure even the smallest defects are visible. The Radiometer verifies this requirement.

- Fluorescent Liquid Penetrant Testing (Fluorescent PT):

- Function: Similarly, it measures the necessary UV intensity to activate the fluorescent penetrant, aiding in the detection of surface-breaking defects on non-ferromagnetic materials.

- Visible Light Illumination Measurement:

- Function: Measures the ambient light (background light) in the inspection area. Too much visible light can “wash out” the fluorescent indications, reducing the test’s sensitivity. The meter ensures ambient light remains below the maximum allowable threshold (e.g., below or ).

2.3. Ensuring Occupational Safety 🛡️

UV Exposure Monitoring: Beyond NDT applications, companies use Radiometers to measure workers’ exposure to ultraviolet radiation from UV light sources in labs, welding operations, or sterilization equipment. This ensures exposure levels remain within safe limits to protect eyes and skin.

2.4. Other Specialized Applications

- UV Lamp Performance Check: Assessing the efficiency and intensity decay of UV lamps used in medical, industrial, or research settings.

- Curing Process Control: Measuring UV intensity in UV Curing systems used to dry inks, coatings, or adhesives, ensuring the curing process is complete and uniform.

3. The Vital Role of Radiometer Calibration

In NDT, a Radiometer’s measurement result serves as the legal basis for accepting or rejecting a critical component (e.g., aerospace, oil & gas, nuclear parts). Therefore, calibration is absolutely mandatory.

3.1. Ensuring Accuracy and Standard Compliance

- Measurement Precision: The UV intensity of light sources naturally degrades with usage. If the Radiometer is uncalibrated, it can report incorrect values.

- Example: The meter reports an intensity of , but the actual intensity is only . Consequently, the inspection occurs under insufficient intensity, potentially missing dangerous defects.

- Standard Requirements: International NDT standards (ASTM, ISO, MIL-STD) and industry regulations (Aerospace, Automotive) require that Radiometers be calibrated periodically (typically 6 or 12 months) by an accredited laboratory, with traceability to NIST or other national standards.

3.2. Guaranteeing Test Sensitivity and Quality

- Defect Detection: The sensitivity of fluorescent materials directly depends on UV intensity. Calibration ensures the intensity stays within the optimal “window” (not too low to miss defects, not too high to cause harm).

- Eliminating Subjectivity: By providing a quantifiable measurement, calibration eliminates inspector subjectivity and ensures process consistency across shifts or different facilities.

3.3. Consequences of Skipping Calibration

- Safety Risk: If the device misjudges the UV intensity, critical defects can be overlooked, leading to catastrophic component failures and accidents (e.g., in aircraft, bridges, pressure vessels).

- Legal Issues: In the event of product failure, NDT records are scrutinized. If the Radiometer lacks valid calibration certification, the inspection results may be declared invalid, leading to legal liability and significant financial loss for the company.

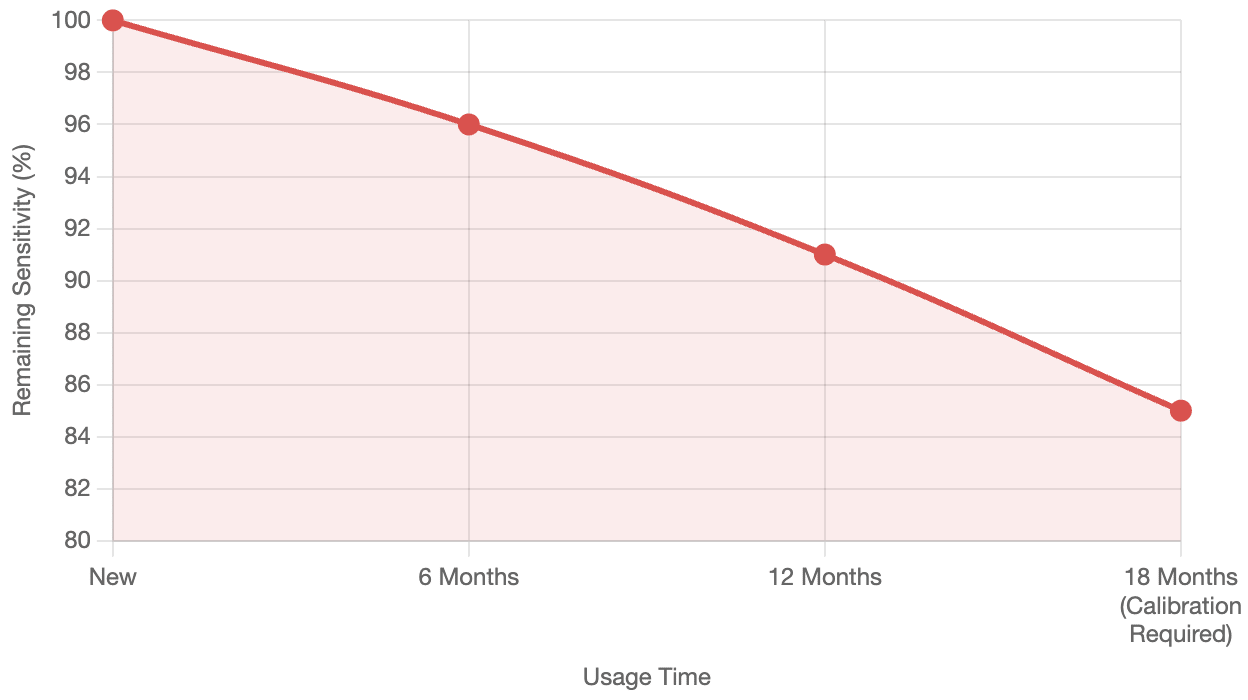

Sensor Degradation Over Time

The graph shows how the sensitivity of the photodetector decreases after every 6 months of use, leading to readings that are lower than the actual intensity.

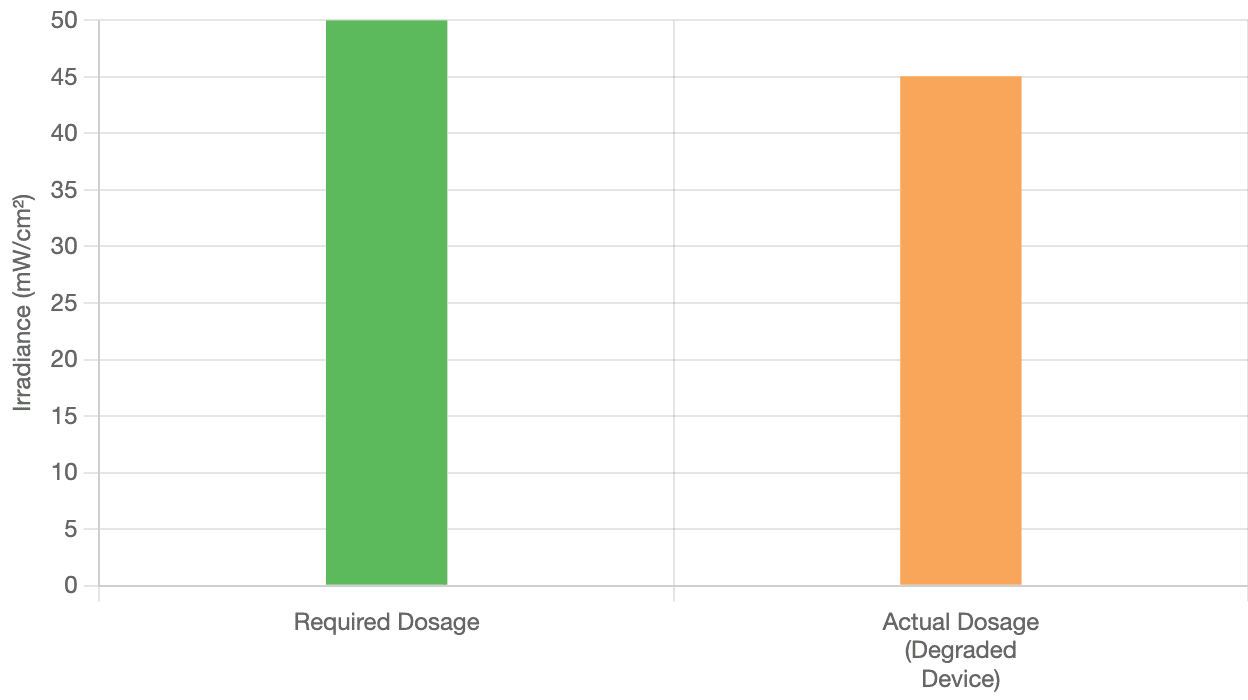

Impact of a 10% Error in Medical Therapy

A small measurement deviation can cause ineffective treatment or risk patient safety.

Why Regular Calibration is Imperative

Ensure Safety

Prevents excessive radiation exposure in medical treatments and guarantees that industrial products meet safety standards.

Compliance & Traceability

Provides auditable evidence traceable to international standards (e.g., NIST, ISO), mandatory in regulated industries.

Optimize Costs

Avoids waste from failed products, optimizes energy usage, and extends the operational life of equipment.

THE CALIBRATION TRILOGY

Accurate measurement is the foundation of high standards. Regular calibration is the only way to guarantee these three critical outcomes.

SAFETY First

QUALITY Guaranteed

SMART Investment

Calibration Cycle:

Typically 6–12 Months

Conclusion

The Radiometer is a precise measuring device that forms the foundation of fluorescent Non-Destructive Testing procedures. Its ability to accurately measure UV and visible light intensity is a prerequisite for ensuring the test’s sensitivity and the product’s safety.

Periodic Radiometer Calibration is more than just procedural compliance; it is quality assurance insurance for every critical product. It ensures that the smallest cracks are not missed, helping to maintain the highest safety standards in the most demanding industries.