3.1. Ensuring Measurement Integrity and Traceability

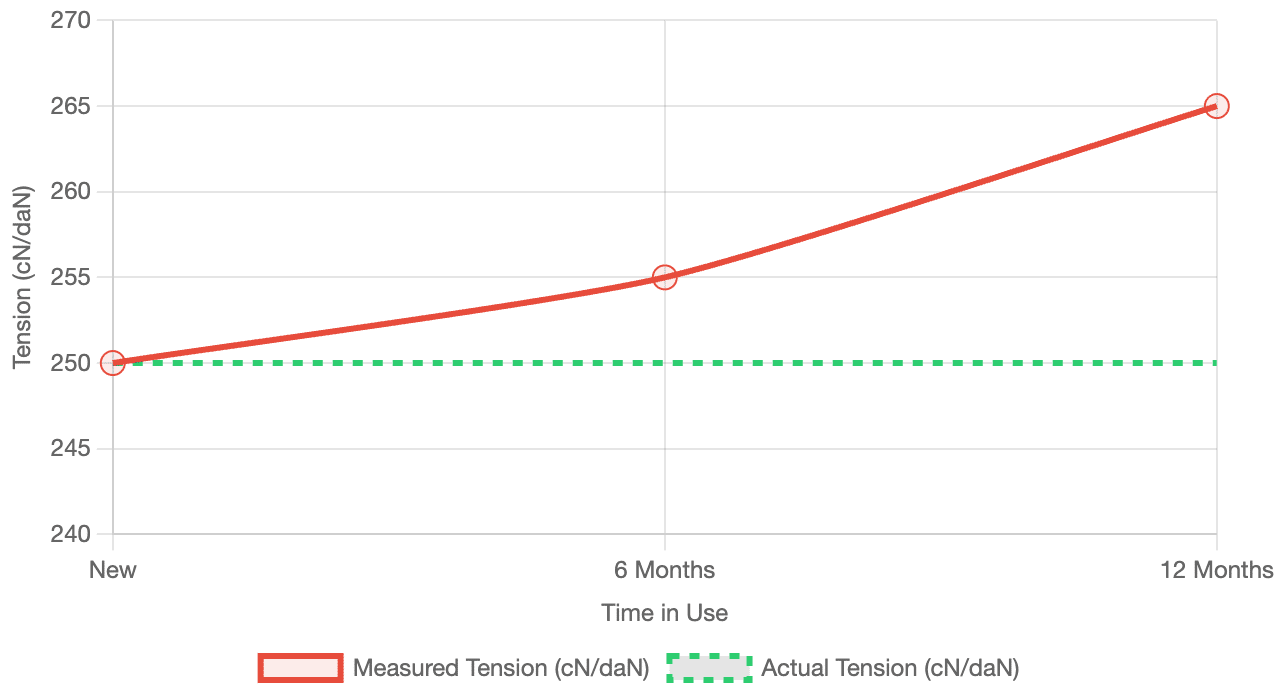

- Preventing Cumulative Error: The internal load cell of a tension meter tends to “drift” due to repeated loads and temperature changes. Therefore, regular calibration corrects this drift, ensuring that measured today still equals measured yesterday.

- Standard Traceability: Above all, calibration provides measurement traceability to international (SI units) or national standards (e.g., NIST, DKD). This is indispensable as evidence in ISO 9001 audits and other legal industry requirements.

3.2. Optimizing Processes and Extending Equipment Life

- Maximizing Operating Speed: When technicians trust the accuracy of a calibrated tension meter, they can increase production line speeds to their maximum safe limits. This leads to increased throughput without sacrificing quality.

- Asset Protection: Excessive tension not only damages the material. It also overstresses bearings, guide rollers, and the braking systems of winding machines, significantly reducing the lifespan of expensive equipment. Moreover, calibration helps accurately define these safe limits.

3.3. Identifying and Compensating for Sensor Errors

- Multi-Point Calibration: During calibration, technicians test the device at various tension points across its full range. The purpose is to create a calibration curve. Thanks to this, any linearity or hysteresis errors of the sensor can be identified and compensated for.

Conclusion

The Tension Meter is an indispensable diagnostic tool — the “nervous system” of any web material production line. It functions as a precise force-sensing organ, continuously monitoring the delicate balance of tension applied to materials such as films, foils, wires, or textiles during manufacturing. By providing quantitative real-time feedback, it enables operators and automation systems to make immediate process adjustments, ensuring stability, uniformity, and efficiency across production stages.

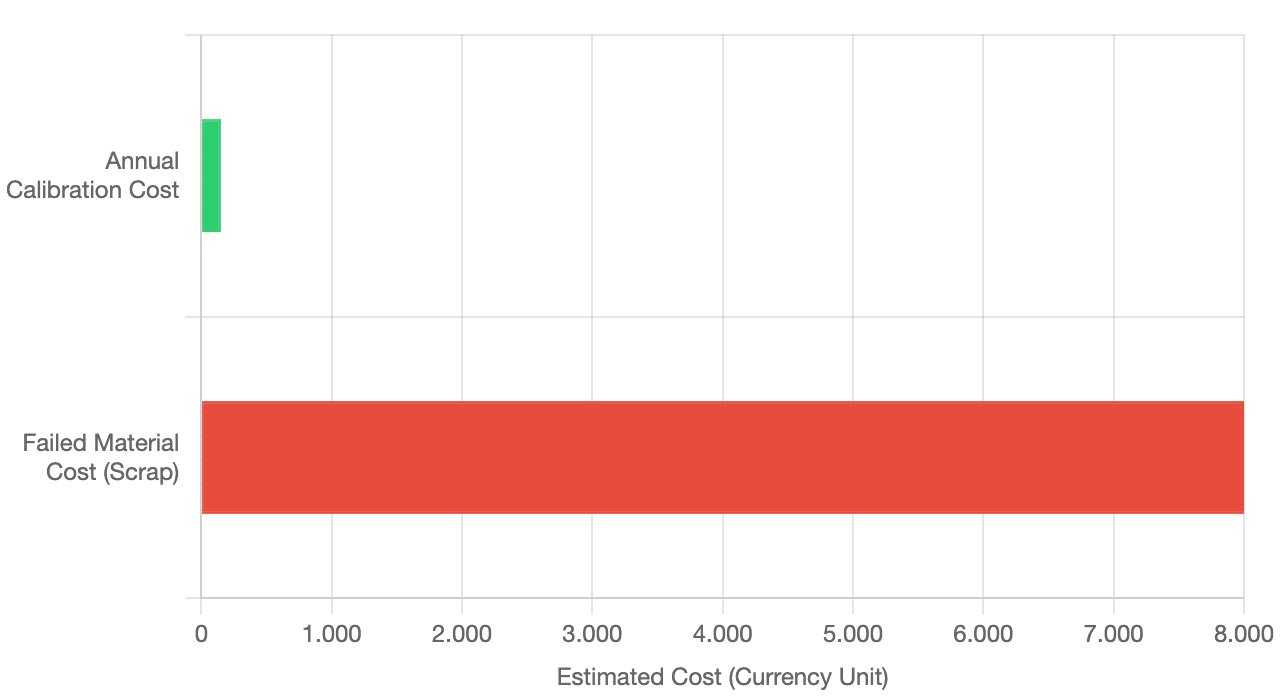

However, the accuracy of these readings depends entirely on periodic and precise calibration. Tension Meter Calibration serves as the foundation of quality assurance, ensuring that every reading reflects the true mechanical behavior of the material under stress. More than a technical requirement, it represents a strategic investment — one that minimizes material waste, prevents machine wear, enhances overall process reliability, and strengthens customer confidence in the consistency and excellence of the final product.