Impulse Testers: A Lifesaving Tool and the Role of Calibration in the Medical Industry

In the modern medical industry, electronic technology is at the core of everything. From complex diagnostic imaging equipment like MRI machines to life support devices and sophisticated implants, all rely on electricity to function. However, these devices must operate in an environment full of electrical risks, from nearby lightning strikes to power grid surges and static electricity from people. Even a small electrical malfunction can lead to catastrophic consequences, posing a direct threat to a patient’s life. To ensure these devices operate safely and reliably under all conditions, manufacturers use a specialized tool: the impulse tester. This device simulates unwanted high-voltage electrical events to test a product’s resilience. This article will delve into the indispensable applications of impulse testers in the medical field and clarify the vital importance of impulse tester calibration to protect human lives.

1. What is an Impulse Tester, and Why Are They Essential in Medicine?

An impulse tester is a specialized device. It generates high-voltage electrical pulses with a predetermined waveform and intensity. Its purpose is to simulate abnormal electrical events like lightning strikes, voltage surges, or electrostatic discharge (ESD). In the medical industry, using these devices provides a clear benefit. It allows manufacturers to replace unpredictable real-world electrical stress with controlled, repeatable lab tests.

Standard electrical safety tests only check basic function. In contrast, impulse testers check a device’s resilience. They ensure the device not only works but can also withstand unexpected electrical shocks. This is crucial because medical devices must operate 24/7 in a complex and risky electrical environment.

2. Groundbreaking Applications of Impulse Testers in the Medical Industry

The applications of impulse testers span across various medical fields, from the smallest devices to the most complex systems.

- Implantable and Life-Support Devices: This is one of the most critical applications. Devices like pacemakers, defibrillators, and insulin pumps are implanted in the human body. They must withstand high-voltage electrical events from external sources. The impulse tester simulates voltage spikes from nearby lightning strikes or power incidents. This ensures the device remains stable and does not harm the patient.

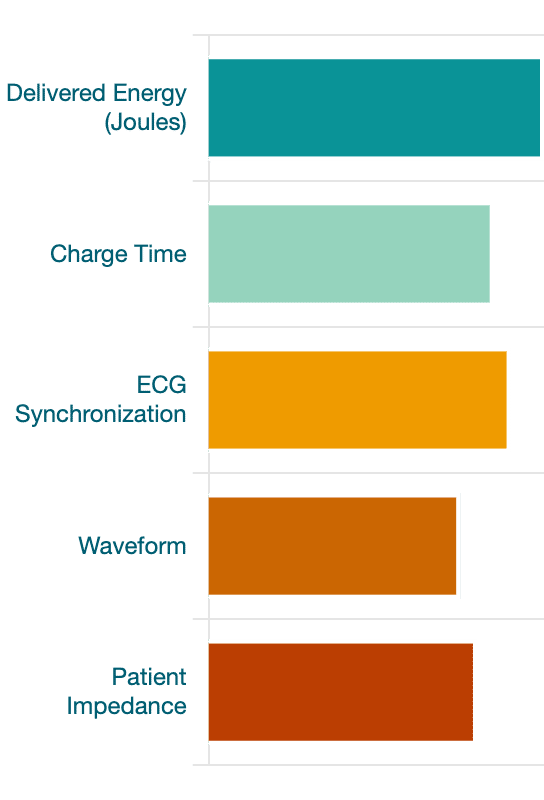

Application: Defibrillator Analysis

Analyzers test critical parameters to ensure a defibrillator delivers a precise and timely life-saving shock. The chart below shows the distribution of the most critical test items.

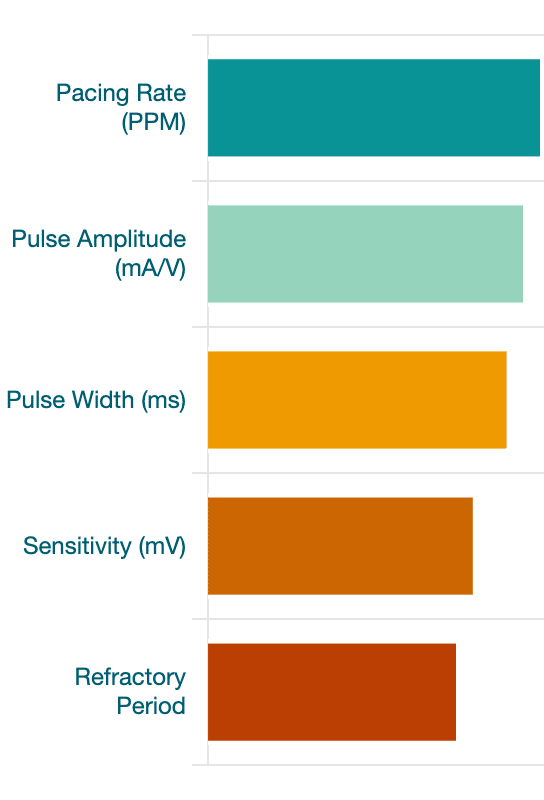

Application: Pacemaker Analysis

For external pacemakers, testing ensures that electrical pulses are delivered consistently and accurately to maintain a patient’s heart rhythm. The key parameters tested include:

- Surgical Robotics and High-Precision Instruments: The introduction of surgical robots (like the da Vinci system) has revolutionized the operating room. These machines use extremely sophisticated electronic systems and servo motors. They require absolute precision. Impulse testers ensure these robots are immune to electromagnetic interference from other operating room equipment. Examples include electrosurgical knives or anesthesia machines.

- Wearable Medical Devices and Medical IoT: This is the hottest trend today. Devices like smartwatches with ECG functions and continuous glucose monitors must operate safely in an everyday environment. They can be exposed to electrical shocks from static electricity or small voltage spikes from other household appliances. Impulse testers help manufacturers confirm their products can resist these events. This ensures user safety and data integrity.

- Diagnostic Imaging and Lab Equipment: Large-scale systems like MRI, CT, X-ray machines, and automated lab analyzers also need testing. Hospital environments often have sudden voltage changes. This can affect diagnostic results. Impulse testers simulate these conditions. They ensure these devices still provide clear images and accurate results.

3. Impulse Tester Calibration: The Gold Standard for Absolute Reliability

Why is Impulse Testers Calibration Matters?

of medical device failures can be prevented with proper routine maintenance and calibration.

Calibration ensures that life-saving devices operate within safe and effective limits, directly impacting patient outcomes.

The role of an impulse tester is only meaningful if it operates with absolute accuracy. An uncalibrated impulse tester can generate incorrect electrical pulses. This could lead to undiscovered weaknesses in medical devices. The consequence is an unsafe product that could be released to the market, endangering patients.

Impulse tester calibration is a mandatory process. It ensures the tester’s output parameters are always accurate against international standards. Specifically, calibration ensures:

- Accuracy of Impulse Voltage: It ensures the generated high voltage matches the required value. A pulse that is too weak may not find a device’s weak point.

- Waveform and Rise/Fall Time: It ensures the shape of the electrical pulse and the speed of the voltage increase/decrease conform to standards. These standards accurately simulate real-world events.

- Compliance with Standards: International medical safety standards, like IEC 60601, have strict requirements for impulse testing. Calibration helps manufacturers prove they have strictly followed these requirements. This is crucial for gaining approval to market products globally.

Standards and Regulations

Calibration must adhere to international standards and national regulations to ensure consistency and accreditation.

-

✓IEC 60601International standard for basic safety and essential performance of medical electrical equipment.

-

✓AAMI DF80Association for the Advancement of Medical Instrumentation standard for defibrillators.

-

✓National Health Authority RegulationsSpecific guidelines and requirements from the local medical regulatory bodies.

4. The Future of Impulse Testing in Medicine

The medical industry is entering a new era of connectivity and data. Medical devices are increasingly integrated. They connect via wireless networks like 5G and Wi-Fi. This creates a new testing challenge.

- Testing for Connected Devices: Impulse testers will need to simulate voltage spikes that affect devices. At the same time, they must ensure their wireless connections are not interrupted.

- Automation and AI: The testing process will become increasingly automated. AI can be used to analyze data and predict potential weaknesses of devices. This saves time and increases the accuracy of the testing process.

Conclusion

An impulse tester is an indispensable tool. It ensures electronic medical devices operate safely and reliably. From life-saving implants to surgical robots, all must pass these rigorous tests. However, an impulse tester’s value depends entirely on its accuracy. Therefore, periodic impulse tester calibration is a mandatory investment. It is the core factor that helps manufacturers build trust, comply with the highest safety standards, and ultimately protect the lives of patients worldwide.