Precision is the heartbeat of the manufacturing world. Whether you are formulating a new pharmaceutical syrup, ensuring the “mouthfeel” of a premium Greek yogurt, or testing hydraulic fluids for aerospace, viscosity is the critical parameter. However, a viscometer is only as reliable as its last calibration.

In the United States, where regulatory oversight from the FDA and ASTM is stringent, viscometer calibration is more than a maintenance task—it is a compliance necessity. This guide dives deep into the technical nuances of calibration, from ISO 17025 Viscosity standards to the practicalities of Brookfield calibration.

1. Verification vs. Calibration: Know the Difference

In many lab environments, the terms “verification” and “calibration” are used interchangeably, but in the world of metrology, they serve distinct purposes.

Internal Verification (The Daily Check)

Verification is a performance check conducted by lab technicians using Viscosity Standards (certified oils). It answers the question: “Is my instrument still reading within an acceptable range today?” This should be done frequently—daily or before every critical batch.

Professional Calibration (The Annual Audit)

Calibration is a formal, comprehensive process usually performed by an accredited third-party laboratory. This process involves comparing the instrument against a primary standard of higher accuracy. The result is a Calibration Certificate that provides a statement of uncertainty, essential for ISO 17025 Viscosity compliance.

2. The Gold Standards: ISO 17025 and NIST Traceability

For American labs, two acronyms reign supreme: ISO and NIST.

Why ISO 17025 is the Benchmark

ISO/IEC 17025 is the international standard for testing and calibration laboratories. An ISO 17025 Viscosity accreditation means the lab has demonstrated technical competence and the ability to produce valid results. If your facility undergoes audits (ISO 9001, FDA, or SQF), having your viscometer calibrated by an 17025-accredited provider is often non-negotiable.

NIST Traceability

The National Institute of Standards and Technology (NIST) provides the ultimate reference points for measurements in the U.S. When you purchase Viscosity Standards, ensure they are “NIST traceable.” This means the accuracy of that oil can be traced back through an unbroken chain of comparisons to NIST’s primary reference materials.

3. Technical Deep Dive: The Secret to Accurate Readings

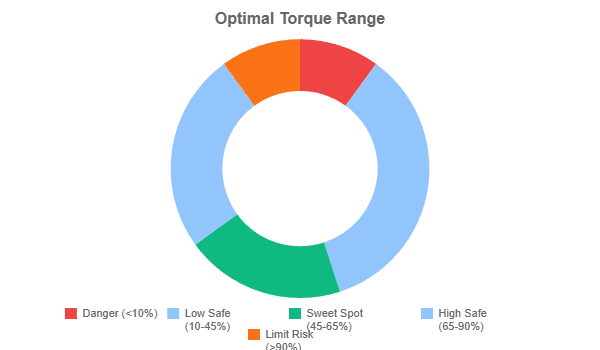

The 10% – 90% Torque Rule

For rotational viscometers, torque percentage is the single most important metric for accuracy.

Digital viscometers are typically accurate to ±1% of the full-scale range.

Operating outside the optimal window introduces significant error.

The Danger Zone (<10%)

High relative error due to spring sensitivity.

The Sweet Spot (45% – 65%)

Maximum repeatability and linearity.

The Limit (>90%)

Risks “bottoming out” or damaging the spring.

Viscometer Torque Range Utilization

Visualizing the operational range of a standard rotational viscometer.

Beyond having the right paperwork, successful calibration depends on mastering the physics of the measurement.

The 10% – 90% Torque Rule

If you are using a rotational viscometer, the Torque percentage is your most important metric. Most digital viscometers, especially during a Brookfield calibration process, are designed to be accurate within $\pm1\%$ of the full-scale range.

-

The Danger Zone: Any reading below 10% torque is prone to high relative error due to the mechanical sensitivity of the spring or transducer.

-

The Sweet Spot: For maximum repeatability, always aim for a torque value between 45% and 65%.

-

The Limit: Exceeding 90% torque risks “bottoming out” the spring, which can lead to permanent damage and inaccurate data.

Thermal Equilibrium: The “Patience” Factor

Viscosity is highly temperature-dependent. For many oils, a change of just $0.1^{\circ}C$ can shift the viscosity reading by $1\%$ to $3\%$.

-

The “Soaking” Rule: Never rush a measurement. After immersing the spindle in the sample or standard, allow at least 15 to 30 minutes for the spindle, the fluid, and the container to reach thermal equilibrium. Using a circulating water bath is highly recommended over simple room-temperature stabilization.

Spindle Integrity & Maintenance

A microscopic scratch or a slight bend in a spindle can change its surface area and flow characteristics.

-

The Wobble Test: Spin the spindle at a low RPM in the air. If you notice any “wobble” or eccentricity, the spindle is likely bent and should be replaced.

-

Cleaning: Use appropriate solvents that leave no residue. Even a thin film of dried resin from a previous test can significantly alter the results of your next calibration check.

4. Step-by-Step: Standard Viscometer Calibration Procedure

Follow this streamlined workflow to ensure your equipment remains within tolerance:

-

Level the Instrument: Use the bubble level on the viscometer. An unlevel machine creates friction in the pivot point, leading to erratic torque.

-

Attach the Guard Leg: Often overlooked, the guard leg (for Brookfield-style meters) defines the boundary conditions of the fluid. Calibrating without it when it was designed to be used will result in an offset.

-

Select the Right Viscosity Standard: Choose a fluid that puts your expected reading in the middle of the torque range at your chosen speed.

-

Immerse to the Groove: Ensure the fluid level is exactly at the immersion groove on the spindle shaft. Under-filling or over-filling changes the “wetted surface area,” causing immediate error.

-

Record Multiple Points: Don’t just check one speed. Check a “Low, Medium, High” range to ensure the linearity of the instrument’s response.

5. Troubleshooting: Common Calibration Pitfalls

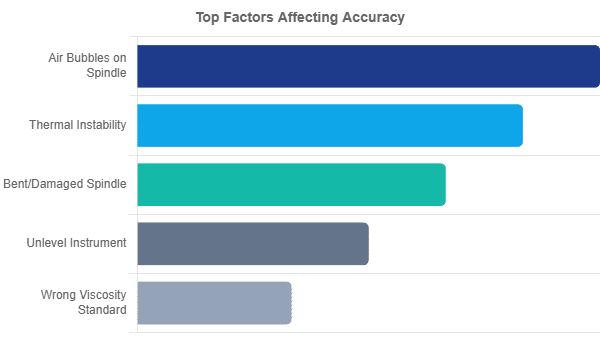

Common Calibration Pitfalls

Insight: Air bubbles are the most frequent “silent killer” of accurate readings,

often acting as insulators that displace fluid volume on the spindle.

Troubleshooting & Maintenance

If verification fails, check the “usual suspects” before sending for repair.

Mechanical integrity is just as crucial as the fluid standard.

💧

The “Wobble” Test

Spin the spindle in the air. Any eccentricity means it is bent and needs replacement.

🪄

Entry Angle

Enter fluid at an angle to roll air bubbles away from under the spindle disk.

🔬

Newtonian Only

Never calibrate with shampoo or paint. Use certified Newtonian oils.

If your verification fails, check these “usual suspects” before sending the unit for repair:

-

Air Bubbles: Bubbles trapped under the spindle or against the shaft act as insulators and change the fluid displacement. Always tilt the spindle when immersing it to “roll” air bubbles out.

-

Non-Newtonian Confusion: Remember that Viscosity Standards are Newtonian fluids (their viscosity doesn’t change with shear rate). If you try to calibrate using a non-Newtonian sample (like paint or shampoo), your results will never be consistent.

-

The Wrong Spindle Entry: Always enter the fluid at an angle. Dropping a spindle straight down often traps a large air pocket in the center of the disk.

6. When to Call the Experts?

While daily verification is your responsibility, professional intervention is required if:

-

The instrument fails to zero itself during the “Auto Zero” phase.

-

The pivot point or jewel bearing shows signs of wear (erratic “hunting” for a stable torque).

-

Your industry requires a formal ISO 17025 Viscosity certificate for legal or safety compliance.

Most experts recommend a professional Brookfield calibration and mechanical tune-up at least once every 12 months.

Conclusion

Mastering viscometer calibration is a blend of scientific discipline and technical patience. By adhering to the 10-90% torque rule, maintaining thermal equilibrium, and using NIST-traceable viscosity standards, you protect your lab’s reputation and your company’s bottom line.