When a surgeon places their hand on a scalpel, they are not just trusting their own experience and talent. They are placing absolute faith in an invisible world. A world of micrometers and nanometers, where perfection is the only currency. This trust extends from the surgeon’s hand to the team in the operating room, and ultimately, to the patient waiting for a better life. Hidden within every instrument, every implant, and every diagnostic machine is a story of meticulousness, where a small flaw can have a monumental outcome. The silent hero of that story, the force that guarantees this unseen perfection, is surface flatness calibration.

This is not a dry technical process. It is the art of creating perfection, a vow that every medical device has been crafted to its purest, most flawless form. It is the story of how a perfectly straight line, a perfectly flat surface, becomes the unshakable foundation for a human life.

Part 1: A Symphony of Steel and Silicon

Imagine a human brain being guided by a complex machine. In modern medicine, that brain is the surgeon’s hand. The machine is the set of tools they use. From an electronic scalpel to a finely crafted artificial hip, every surface and every curve has a mission. If the surface of a microsurgical tool is not perfectly flat, it will “betray” the surgeon’s intended cut. It creates a subtle, uncontrolled deviation that can cause unnecessary trauma to delicate tissue. This is a silent sabotage.

Similarly, when an artificial joint is implanted, it is more than just a mechanical part. It is a “perfect handshake” between inert material and living bone. If the surface of that implant is not flawless, the fit will be imperfect. This can lead to improper bone integration, causing silent inflammation, pain, and a heightened risk of infection. The implant fails to live up to its promise. Surface flatness calibration is the “translator” that ensures every component speaks the same language of absolute perfection.

Part 2: The Unsung Hero of Medical Revolutions

The growth of medical technology has created revolutions in patient care. And in each of these revolutions, surface flatness calibration has served as a silent, yet indispensable, hero.

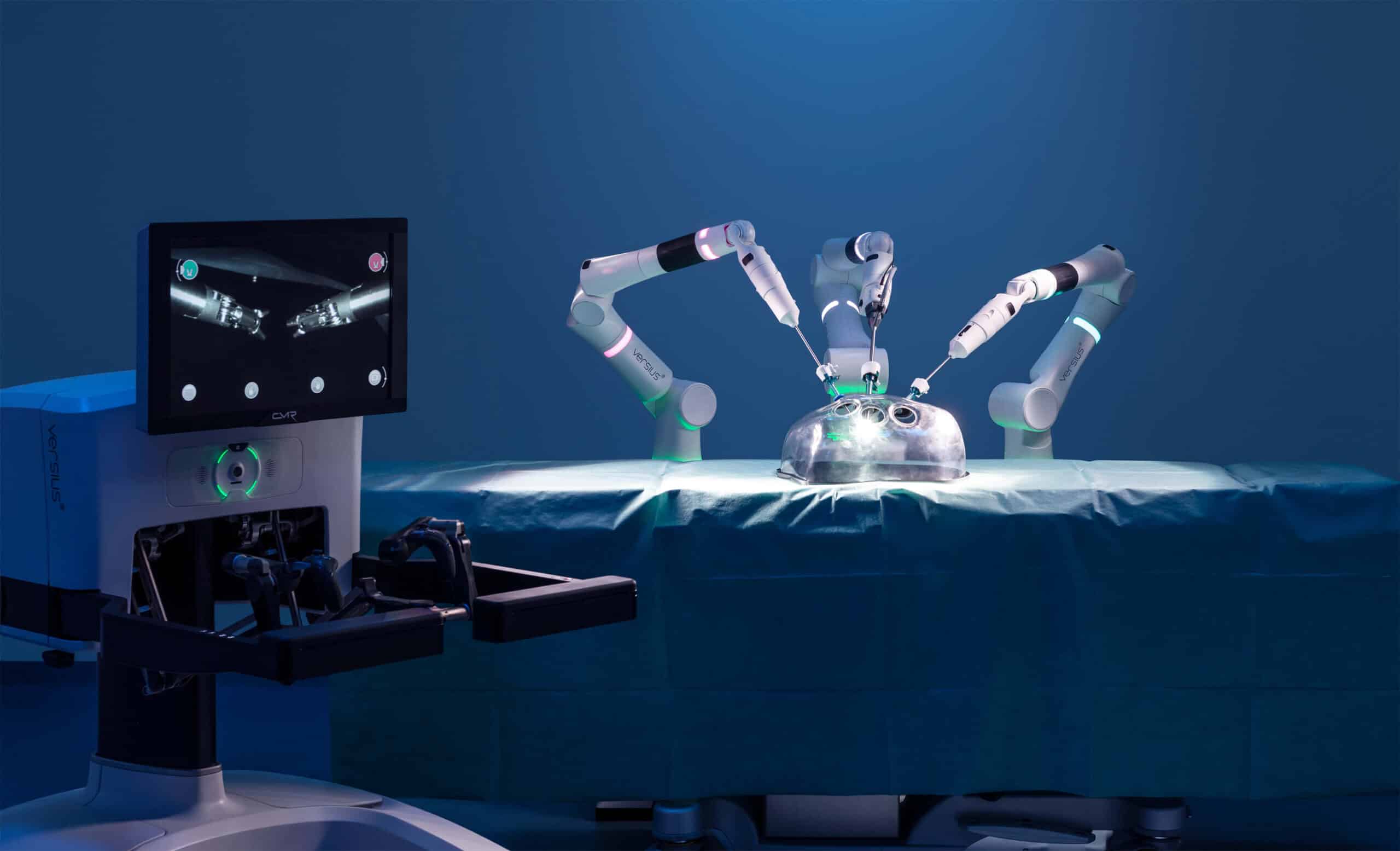

The Story of Surgical Robots: A Dance of Precision

When a surgical robot like the Da Vinci system performs a cut with micrometer-level accuracy, it’s more than a smart machine. It is a dancer. Its every movement depends on a stable, perfectly flat stage. Surface flatness calibration ensures that the surgical table and every joint on the robot’s arm are flawless. This provides the robot with a sense of “touch” and repeatability that far exceeds human capability. It turns numbers into a fluid, precise “dance,” with not a single misstep. This flawless movement gives the surgeon the confidence to perform intricate procedures with unparalleled control.

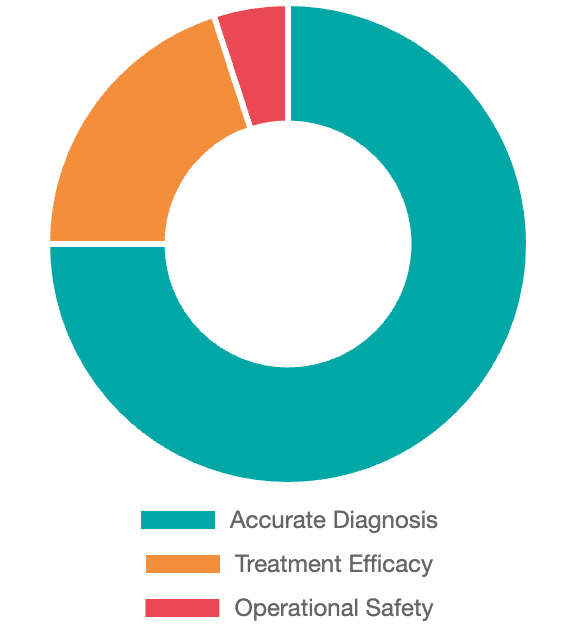

Why Flatness Matters?

In the medical environment, the flatness of equipment surfaces is not just a technical requirement but a foundational factor for diagnostic accuracy, treatment efficacy, and patient safety. An uncalibrated surface can lead to measurement errors, surgical risks, and reduced effectiveness of advanced therapies.

Regular calibration ensures that all critical surfaces meet stringent standards, contributing to a reliable healthcare system.

Direct Impact of Calibration

Critical Applications

CT/MRI Beds

Ensures patients are precisely positioned for clear, undistorted diagnostic images.

Radiotherapy Tables

Vital for ensuring the radiation beam accurately converges on the tumor, protecting healthy tissues.

Surgical Tables

Maintains stability for the patient and precision for surgical instruments, especially robots.

Microscope Stages

Absolute flatness helps maintain stable focus for accurate sample analysis.

The Promise of Personalized Medicine: A Golden Vow

Medicine is no longer “one size fits all.” Now, devices like artificial hips or knee joints can be custom 3D-printed for each patient. This is a profound promise—the promise of a perfect fit, reduced pain, and a faster recovery. This promise can only be kept if the implant is calibrated to perfection. Engineers create a “digital twin” of a patient’s bone structure. The physical implant must then match that digital model with absolute fidelity. The calibration of the 3D-printing bed and the final implant surface ensures it can “shake hands” perfectly with the patient’s bone, fulfilling that golden vow.

Advanced Imaging & Diagnosis: The Eyes of the Medical World

Before a single cut is made, a doctor must have a perfect picture of what’s happening inside the body. Medical imaging devices like MRI and CT scanners are the “eyes” of the medical world.

- The Role of Calibration: Inside these complex machines, the platforms holding the lenses, detectors, and other optical components must be perfectly flat. Any microscopic wobble or deviation in these internal surfaces can introduce distortions into the final image. Surface flatness calibration ensures that these platforms provide a stable, flawless foundation, allowing the imaging device to produce crystal-clear, accurate pictures for a precise and correct diagnosis.

Risks of Neglecting Calibration

Incorrect Diagnosis

Distorted or misaligned medical images can lead to wrong conclusions about a patient’s condition.

Treatment Failure

Off-target radiotherapy or imprecise surgery reduces effectiveness and can harm the patient.

Infection Risk

Uneven surfaces create hard-to-clean gaps where bacteria can thrive and spread.

Equipment Failure

Moving parts on a non-flat surface wear out faster, leading to costly repairs.

Part 3: The Language of Finesse

To ensure this level of perfection, the calibration process itself must be without error. Professional laboratories serve as sanctuaries of precision, using an array of sophisticated tools. This includes massive granite tables that provide a perfectly stable reference plane, as well as laser interferometers and coordinate measuring machines (CMMs). These instruments do more than just measure. They “listen” to and “translate” the language of a surface, revealing any imperfections that are invisible to the naked eye. They are the guardians of a universal language of truth, certifying that the device speaks with perfect clarity.

The process must also adhere to strict standards. Following international guidelines like ISO 13485 is not just a requirement; it is a vow. It is a promise that every product created is the result of not just advanced science, but of unwavering dedication to quality. This dedication creates a documented “chain of traceability,” proving that the device has been certified by experts and is worthy of the trust placed in it.

Conclusion: From Perfection to a Life

From a sharp scalpel to an invisible implant, to every pixel on a diagnostic screen, each medical component carries a heavy responsibility. It carries the responsibility of a human life.

Surface flatness calibration is the silent artisan. It meticulously crafts every detail, ensuring every surface is perfect. It transforms raw numbers and dry theories into a beautiful, tangible reality. That reality is a patient who recovers faster, a diagnosis that is more accurate, and a future free from pain. It is a reality of safety, reliability, and trust. In the end, it is the story of how technology, built on a foundation of precision, can truly touch the human heart. It is not just about accuracy. It is about care.