Introduction to Universal Power Analyzer Calibration

Universal Power Analyzers (UPAs) are essential instruments for measuring voltage, current, power, efficiency, and harmonics in industries such as power electronics, renewable energy, motor manufacturing, and appliance testing.

Because these measurements directly affect product design, compliance reports, and energy-efficiency certifications, regular universal power analyzer calibration is critical to maintain reliable and traceable results.

What Is a Universal Power Analyzer?

A Universal Power Analyzer is a precision instrument designed to:

-

Measure AC/DC voltage and current across multiple channels.

-

Calculate active (W), apparent (VA), reactive power (VAR) and power factor.

-

Evaluate conversion efficiency of inverters, motors, and power supplies.

-

Analyze harmonics and capture instantaneous waveforms.

These capabilities make UPAs indispensable in R&D labs and compliance testing facilities.

Why Calibration Matters

Over time, internal shunts, current sensors, sampling circuits, and reference standards can drift, resulting in measurement errors.

Consequences include:

-

Misinterpreting product efficiency, leading to poor design decisions.

-

Failing to meet international standards (e.g., IEC 62301, Energy Star).

-

Increased costs due to retesting or rejected products.

Routine calibration helps to:

-

Restore measurement accuracy to the instrument’s published specifications.

-

Ensure compliance with ISO/IEC 17025 or ANSI/NCSL Z540.1 as required.

-

Minimize risk and save time by avoiding costly rework caused by inaccurate readings.

The Power of Precision

Why Calibrating Your Universal Power Analyzer is Non-Negotiable

Without regular calibration, an instrument can drift from its original specifications, quietly risking quality, safety, and efficiency.

Potential Annual Accuracy Drift

Small deviations can cascade into failed products, flawed R&D, and costly energy mismanagement.

The Four Pillars of Calibration

Accredited calibration underpins decisions across R&D and production—turning compliance into a strategic advantage.

Calibration Standards and Compliance

At Techmaster Electronics, calibration is offered at three levels

-

Commercial Calibration: NIST-traceable certificate; ideal for in-house quality checks.

-

ANSI/NCSL Z540.1 Calibration: Adds test data and Test Accuracy Ratios (TARs); often required by aerospace and defense industries.

-

ISO/IEC 17025 Accredited Calibration: Performed under ANAB accreditation and globally recognized by ILAC-MRA; includes detailed measurement data and uncertainties, suitable for regulated industries and R&D.

Step-by-Step Universal Power Analyzer Calibration Process

A meticulous, multi-step path ensures accurate, traceable, and fully documented results.

-

Visual Check & Preparation: Inspect connectors, accessories, and warm up the instrument.

-

Environmental Stabilization: Maintain temperature and humidity within recommended limits.

-

Reference Setup: Connect to precision AC/DC sources, reference loads, and high-accuracy standards.

-

Parameter Verification: Test and compare:

-

Voltage and current accuracy across ranges

-

Power measurement linearity at various load levels

-

Harmonic and power-factor measurement accuracy

-

-

Adjustments (If Required): Perform internal calibration following the manufacturer’s procedures.

-

Final Test & Documentation: Issue a calibration certificate with all results according to the selected service level

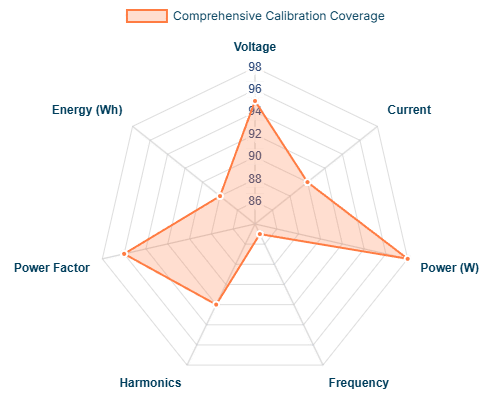

What Gets Calibrated? A Comprehensive Check

A thorough calibration is a highly technical procedure that verifies dozens of functions and ranges across multiple parameters. This ensures that every aspect of the power analyzer is performing to its specified accuracy, providing a complete and trustworthy picture of your electrical system’s health.

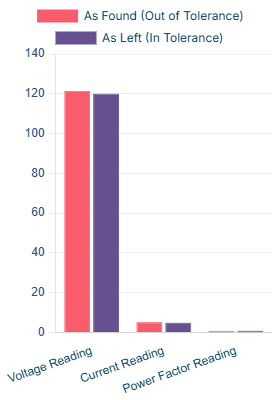

Before vs. After: The Impact of Adjustment

The most critical data from a calibration report are the “As Found” and “As Left” values. “As Found” shows how much the device had drifted out of tolerance. “As Left” data provides proof that after adjustment, the instrument is performing perfectly within its specifications.

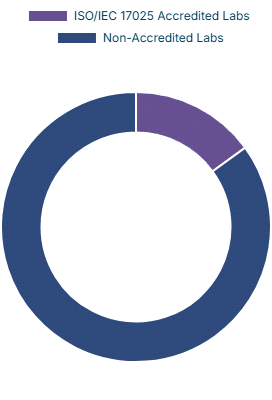

The Gold Standard: ISO/IEC 17025

Choosing an ISO/IEC 17025 accredited laboratory is the only way to guarantee technical competency and traceability. This accreditation is a rigorous, third-party verification that the lab has the systems and expertise to perform accurate calibrations.

Common Issues Revealed During Calibration

-

Voltage or Current Gain Drift: Caused by aging components.

-

Phase-Shift Errors: Affect power factor and efficiency calculations.

-

Non-linearity at Low Currents: Impacts testing of energy-saving devices.

-

Harmonic Measurement Deviations: Can lead to incorrect evaluation of harmonic pollution.

Choosing a Reliable Calibration Partner

Techmaster Electronics provides:

-

30+ years of experience in power and RF calibration services.

-

A global network of labs (USA, Vietnam, Thailand, Mexico) and on-site calibration to reduce downtime.

-

Fast turnaround with convenient pickup & delivery.

-

A secure customer portal to access certificates, recall notices, and manage equipment easily.

-

Integrated repair and rental services to keep operations running even if instruments need extended servicing.

Case Study: Renewable Energy Lab with PM 6000

A renewable-energy testing lab relied on a PM 6000 Universal Power Analyzer to measure inverter efficiency and harmonics.

After more than 18 months without calibration, the lab noticed inconsistencies between the analyzer’s readings and its in-house reference.

The lab sent the PM 6000 to Techmaster Electronics for ISO/IEC 17025 accredited calibration.

Results after calibration:

-

Low-current measurement error corrected to within ±0.1% of spec.

-

Phase-shift between voltage and current channels improved from 0.18° to 0.03°.

-

Data-validation time during testing decreased by 30%.

-

The detailed uncertainty report enabled the lab to pass an IEC 62301 certification audit smoothly.

Maintenance Tips to Extend Calibration Intervals

-

Keep the instrument in a stable environment with controlled temperature and humidity.

-

Avoid overloading voltage or current inputs.

-

Run built-in self-checks regularly to detect early deviations.

-

Use proper leads and accessories to minimize connection errors.