Leak Testers: Ensuring Product Quality and Safety – The Critical Role of Calibration

In modern industries, from medical to automotive, electronics to aerospace, the leak integrity of products and systems is a critical factor. Even a tiny leak can lead to severe consequences: loss of expensive products, environmental contamination, safety risks for users, or equipment failure. Leak Testers address these challenges, offering the ability to detect and quantify microscopic leaks invisible to the naked eye. However, the value of any leak measurement depends entirely on the accuracy of the testing equipment. Therefore, Leak Tester Calibration is an obligatory, periodic step. It ensures that the measured data is reliable, legally valid, and compliant with industry standards.

1. Diverse Applications of Leak Testers

Leak Testers find widespread application across numerous sectors, from manufacturing quality control to system maintenance.

🚗 Automotive Industry

💉 Pharmaceutical & Medical

💡 Electronics & Semiconductor

🚀 Aerospace Industry

🍔 Food & Beverage

1.1. Automotive Industry

In the automotive industry, leak integrity directly impacts performance, safety, and fuel efficiency.

- Fuel and Brake Systems: Testing the leak-tightness of fuel tanks, fuel lines, brake lines, vacuum brake systems, and emission-related components is crucial. This prevents leaks of flammable liquids or toxic gases.

- Air Conditioning Systems: Ensuring that AC systems do not leak refrigerants is vital. Leaks affect cooling efficiency and have environmental impacts.

- Engines and Transmissions: Checking the integrity of gaskets, seals, engine assemblies, and transmissions prevents oil or coolant leaks, extending engine life.

1.2. Pharmaceutical and Medical Industry

In healthcare, leak integrity is vital for ensuring sterility and product efficacy.

- Pharmaceutical Packaging: Testing the leak-tightness of blister packs, sterile syringes, vials, and IV bags prevents microbial contamination or loss of drug potency.

- Medical Devices: Ensuring implants, ventilator components, and catheters are leak-free is critical, especially for devices that must maintain sterility.

- Containment Equipment: Checking the integrity of enclosures and packages that maintain sterile or inert gas environments.

1.3. Electronics and Semiconductor Industry

Sensitive electronic components require high leak integrity for stable and long-term operation.

- Component Housings: Testing the leak-tightness of electronic component housings (e.g., MEMS, sensors) protects them from moisture, dust, and contaminants.

- LCD/OLED Displays: Ensuring the integrity of display layers prevents moisture ingress, which can cause damage or degrade display quality.

1.4. Aerospace Industry

In extreme pressure environments, leaks can be catastrophic.

- Hydraulic and Pneumatic Systems: Testing the leak integrity of these critical systems on aircraft ensures flight safety.

- Equipment Enclosures: Ensuring the integrity of pressurized cabins, environmental control systems, and critical equipment enclosures on aircraft and spacecraft.

1.5. Food and Beverage Industry

Packaging integrity directly impacts shelf life and food safety.

- Food Packaging: Testing the leak-tightness of food pouches, milk cartons, and beverage bottles prevents air or bacterial ingress, or product leakage.

- Gaseous Products: Ensuring carbonated beverages or other gas-filled products do not lose their gas content.

2. The Critical Role of Leak Tester Calibration

Like all measuring instruments, Leak Testers are only reliable when periodically calibrated.

🎯 Optimal Accuracy

Calibration prevents sensor drift, maintaining precision and sensitivity.

📜 Compliance

Ensures ISO 17025 / FDA traceability with legal calibration certificates.

📉 Minimize Risk

Avoid costly recalls and faulty product acceptance with regular calibration.

📋 Support QA

Reliable data enables Quality Assurance teams to analyze and optimize processes.

🔧 Extend Lifespan

Detect and correct sensor drift early, optimizing uptime and device life.

2.1. Ensuring Accuracy and Sensitivity

Leak Testers operate on various principles (differential pressure, vacuum decay, mass spectrometry). Each principle involves sensors and transducers that require adjustment.

- Sensitivity Check: Calibration determines the smallest leak detection threshold the instrument can measure. If the device drifts, it might miss dangerous leaks.

- Quantitative Accuracy: Calibration helps the Leak Tester accurately measure the leak rate, typically expressed in units like or . This is crucial for determining if a leak level is acceptable.

2.2. Compliance with Standards and Regulations

In many industries, leak testing is not just a best practice but a legal requirement.

- ISO, ASTM, FDA Requirements: Standards like ISO 9001, ASTM (American Society for Testing and Materials), and FDA (Food and Drug Administration) regulations mandate that testing equipment be calibrated periodically and show traceable evidence.

- Product Certifications: To achieve product certifications (e.g., CE Marking), manufacturers must demonstrate that their products have undergone leak tests using calibrated equipment.

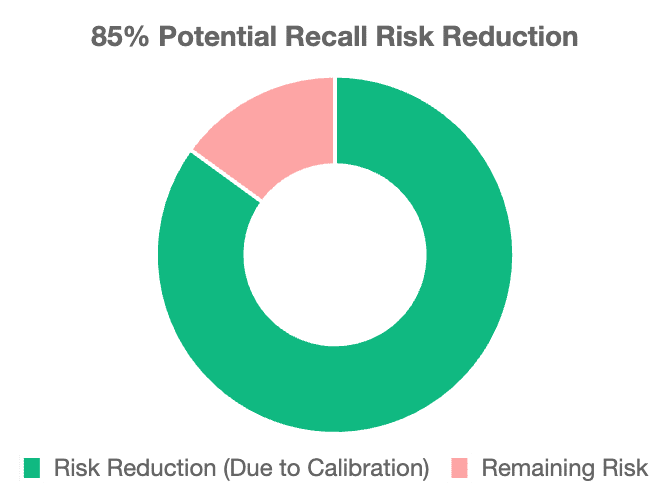

2.3. Mitigating Risks and Operating Costs

Using calibrated Leak Testers offers significant economic benefits.

- Preventing Product Failures: Early leak detection prevents defective products from reaching the market. This avoids costly recalls, warranty claims, and litigation.

- Optimizing Manufacturing Processes: Accurate data from calibrated equipment helps manufacturers adjust processes, reduce defect rates, and improve efficiency.

- Workplace Safety: In industries handling chemicals, toxic gases, or flammable substances, calibrated Leak Testers ensure timely detection of hazardous leaks, protecting worker safety.

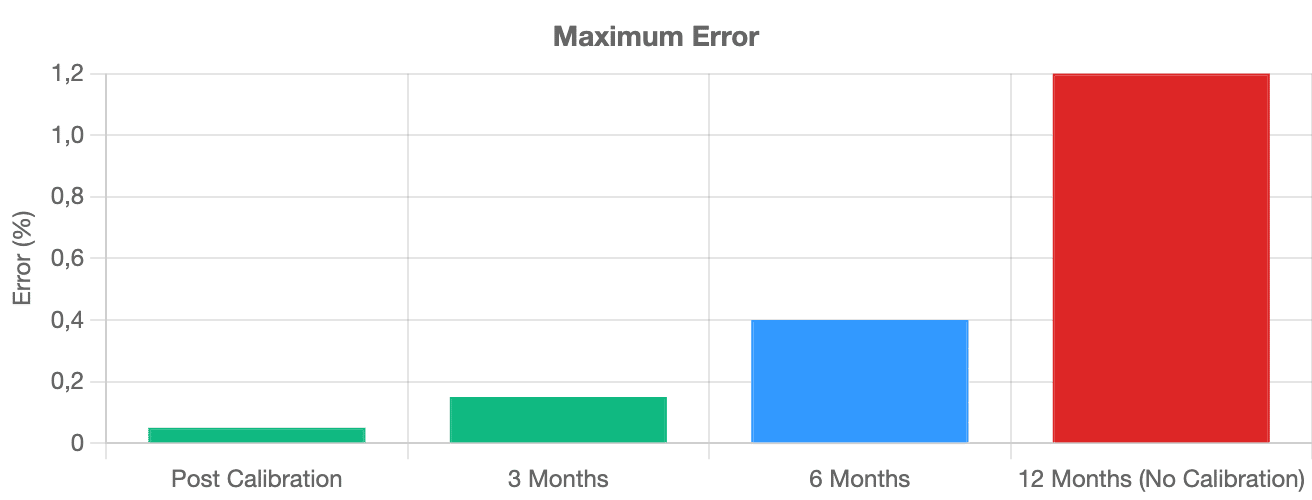

CALIBRATION DATA & RISK

Measurement Drift Over Time

Impact on Recall Risk

3. Types of Leak Testers and Their Calibration Considerations

The type of leak tester impacts its calibration approach.

- Pressure Decay/Vacuum Decay Testers: These common testers measure pressure drop over time. Calibration involves verifying the accuracy of the pressure transducer and the timer, using a known volume and a precision leak standard (calibrated orifice).

- Mass Spectrometer Leak Detectors (MSLD): Highly sensitive, these detect tracer gases (like Helium). Calibration involves introducing a known amount of tracer gas using a calibrated leak standard to verify the detector’s response and sensitivity.

- Bubble Test Equipment: While simpler, even visual methods rely on standardized procedures. Calibration ensures consistent pressure application and verifiable bubble sizes for comparative analysis.

- Flow Testers: These measure the flow of gas or liquid through a component. Calibration verifies the flow meter’s accuracy across its range.

4. Calibration Frequency and Traceability

Calibration frequency depends on several factors: the tester’s usage intensity, environmental conditions, and regulatory requirements. Typically, annual calibration is standard, but some critical applications may require more frequent checks.

Traceability is paramount. Calibration must be performed by an ISO/IEC 17025 accredited laboratory. This ensures that the calibration standards used are themselves traceable to national or international measurement standards, providing an unbroken chain of comparison to the SI units.

PROCESS AND STANDARD FACTORS

🔬 Testing Method

The device must be calibrated according to the intended testing method:

- Differential Pressure testing.

- Tracer Gas method (Helium).

- Vacuum Leak Test.

🔗 Traceability

Calibration must be linked to National Standards through an unbroken chain, ensuring global validity of measurement results.

→ Mandatory requirement of ISO 17025.

📅 Calibration Cycle

The cycle (usually 6 – 12 months) must be based on the device’s risk (Risk-Based Approach) and actual usage, not just the manufacturer’s recommendation.

Conclusion

Leak Testers are indispensable tools in modern manufacturing, ensuring the quality, safety, and reliability of countless products. From the smallest packaging to complex aerospace systems, their ability to detect leaks protects brands, ensures regulatory compliance, and safeguards consumers.

However, the value of every measurement truly gains significance only when Leak Tester Calibration is rigorously performed. This ensures that the results you obtain are accurate, traceable, and legally recognized.

Have you checked the calibration status of the Leak Testers in your facility recently? Do not let a small leak undermine your entire quality system!