Ultrasonic Cleaner: The Optimal Solution for Healthcare, Science, and The Absolute Role of Calibration

In environments demanding absolute sterility and cleanliness—such as laboratories, medical facilities, or precision electronics manufacturing—thoroughly removing contaminants, microorganisms, or residue from instruments and equipment is a significant challenge.Consequently, the Ultrasonic Cleaner has become the gold-standard technology, utilizing sound-wave energy to create tiny vacuum bubbles (cavitation) that achieve deep cleaning even in the most inaccessible areas. As a result, this device protects the accuracy of measuring instruments, extends the lifespan of medical devices, and ensures strict hygiene standards. However, the efficiency of the ultrasonic cleaning process directly depends on the intensity and frequency of the waves generated. Therefore, routine Ultrasonic Cleaner Calibration is a mandatory requirement to verify that the device is operating at optimal power and frequency, ensuring reliable cleaning results every single time.

1. Definition and Principle of the Ultrasonic Cleaner

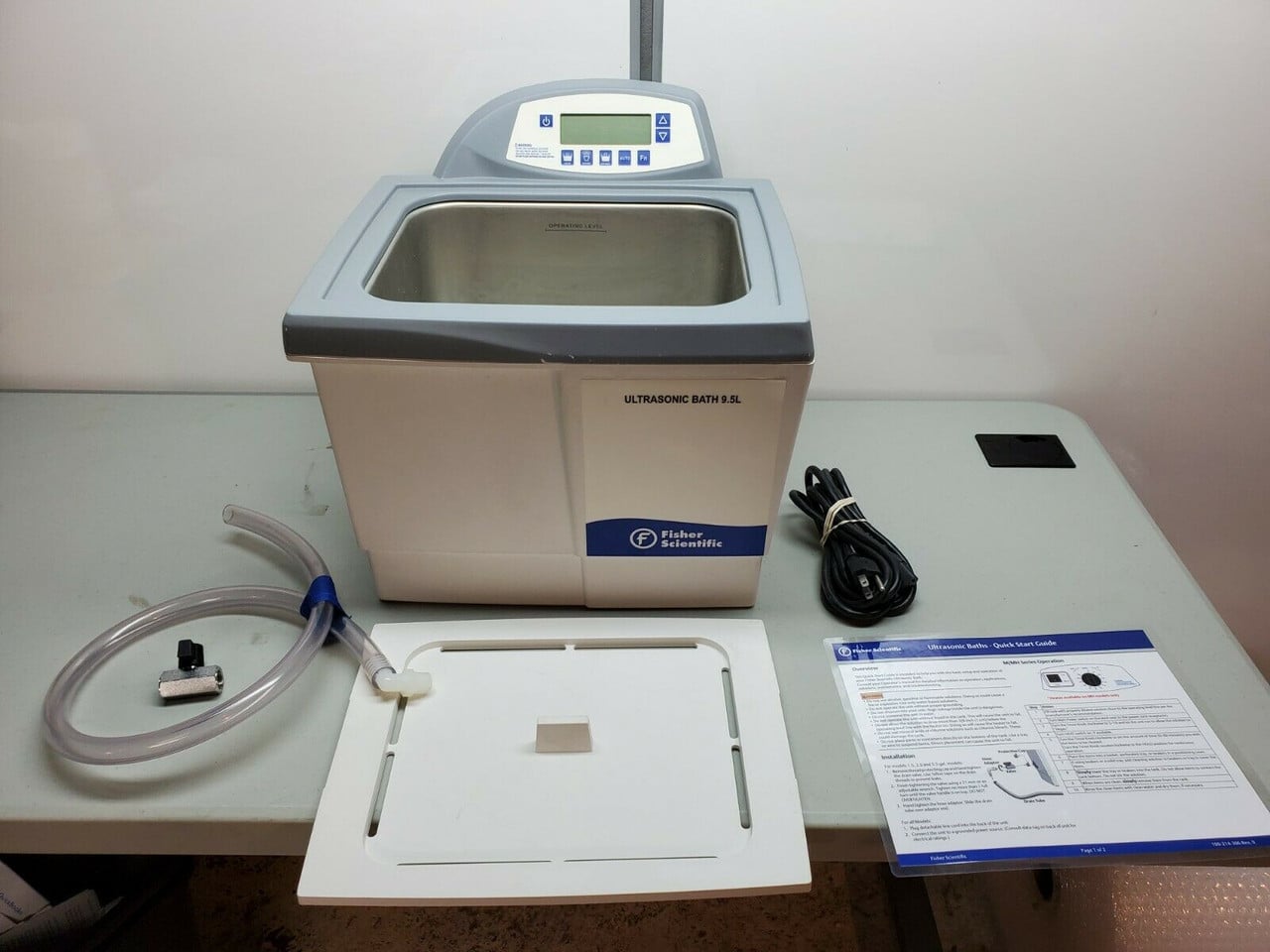

An ultrasonic cleaner is a device that uses high-frequency sound waves to clean objects by creating microscopic bubbles in a liquid. These bubbles, formed through a process called cavitation, implode and generate shockwaves that dislodge dirt, grease, and other contaminants from the surface and crevices of items. They are used to clean a wide range of items, including jewelry, medical instruments, electronics, and auto parts, often in industries, labs, and households.

1.1 Operating Principle

The operating principle of an ultrasonic cleaner is the creation of cavitation, which are microscopic bubbles that form and then rapidly collapse in a cleaning solution. This process is driven by high-frequency sound waves, which are converted from electrical energy by a transducer. The implosion of these bubbles creates tiny, high-energy shockwaves that scrub contaminants off an object’s surface.

1.2. The Cavitation Mechanism

The core principle is converting electrical energy into microscopic vacuum bubbles that implode and remove contaminants effectively.

- Formation and Implosion: As ultrasonic waves travel through the solution, they create cycles of high and low pressure. During the low-pressure cycle, tiny vacuum bubbles are formed (the cavitation process).

- Cleaning Action: When these bubbles collide with the item’s surface and rapidly implode (implosion), they generate enough energy to dislodge and remove stubborn contaminants (such as dried blood, residue, oil, or grease) from surfaces and micro-crevices, all without mechanical scrubbing.

2. Essential Applications of Ultrasonic Cleaning

Ultrasonic cleaning technology is an indispensable standard in industries demanding the highest level of cleanliness.

Medical & Sterilization

Pre-sterilization cleaning of instruments, removing organic soil.

Science & Research

Cleaning glassware and sensitive laboratory equipment.

Electronics Manufacturing

Removing flux and residues from PCBs and micro-components.

2.1. Applications in the Medical and Pharmaceutical Industries

- Sterilization Pre-Treatment: It is the deep cleaning step for surgical, dental, and endoscopic instruments prior to sterilization. Ultrasonic waves are particularly effective at removing organic material, minimizing the risk of cross-contamination.

- Pharmaceutical Manufacturing: Cleaning machine parts, molds, or small containers in a GMP (Good Manufacturing Practice) environment, ensuring no residual contaminants affect product quality.

2.2. Science and Precision Industries

- Laboratory Use: Cleaning complex glassware, pipettes, or sensitive analytical equipment where mechanical scrubbing could cause damage or alter volumetric accuracy.

- Electronics Manufacturing: Removing solder flux residue, dust, or chemical substances from printed circuit boards (PCBs), semiconductor components, and micro-mechanical parts, ensuring optimal performance.

2.3. Key Technical Parameters Requiring Control

The cleaning efficacy of the equipment depends on the strict control of the following parameters:

- Ultrasonic Frequency: Affects the size and energy of the bubbles (e.g., lower frequency for stronger cleaning; higher frequency for gentle, detailed cleaning).

- Power/Intensity: Determines the density and strength of the implosions in the tank.

- Solution Temperature: Influences the action of detergents and the efficiency of cavitation.

3. The Absolute Role of Ultrasonic Cleaner Calibration

Parameter Balance (Static Radar Illustration)

Optimal cleaning efficiency is achieved when there is a balance between Frequency, Power, and Temperature. Deviation reduces cavitation energy or may damage items.

Parameter Balance Model

Energy Uniformity Testing

Calibration verifies the actual cavitation energy density in the tank. Uneven distribution creates ‘Dead Zones’ where instruments are not fully cleaned.

Ultrasonic Energy Distribution in the Tank (W/cm²)

Ultrasonic Cleaner Calibration is the most crucial process to ensure the equipment performs according to its specified technical parameters.

3.1. Performance Verification

- Frequency and Intensity Check: Calibration verifies the actual ultrasonic wave frequency (kHz) and the energy density of the cavitation within the tank. A deviation in frequency or intensity will compromise cleaning effectiveness or potentially damage the items.

- Uniformity Measurement: Specialized instruments (such as a Hydrophone) are used to ensure that the wave energy is uniformly distributed across the entire tank, eliminating “dead zones” where cleaning is ineffective.

3.2. Ensuring Regulatory Compliance

- Sterilization and QC Protocols: In healthcare, proper pre-cleaning is a vital step in the sterilization chain. Calibration provides traceable evidence that the cleaning unit is operating according to required standards, helping to comply with medical safety regulations and quality standards (ISO 9001).

3.3. Calibration of Other Critical Parameters

A comprehensive calibration procedure also includes:

- Temperature Calibration: Ensuring the temperature control system accurately displays and maintains the cleaning solution temperature.

- Timer Calibration: Checking that the device’s timer functions accurately to ensure standardized cleaning cycles.

Conclusion

The Ultrasonic Cleaner is an indispensable tool for achieving the highest levels of cleanliness in critical industries, where even microscopic residues can compromise performance, safety, or sterility. Its true value lies not merely in its ability to clean, but in its capacity to generate powerful, stable, and evenly distributed cavitation—millions of microscopic bubbles that implode with enough force to remove contaminants from even the most intricate surfaces.

However, this sophisticated cleaning mechanism is only as reliable as the calibration behind it. Over time, factors such as transducer wear, temperature drift, inconsistent power delivery, and solution aging can significantly impact cavitation efficiency. When this happens, “dead zones” may appear in the tank, cleaning uniformity decreases, and instruments or components may not achieve the required level of cleanliness.

Therefore, performing routine Ultrasonic Cleaner Calibration is far more than a technical procedure—it is a commitment to process integrity, regulatory compliance, and risk prevention. In medical environments, it protects patient safety by ensuring that surgical and dental instruments are properly prepared for sterilization. In manufacturing and research, it safeguards product quality, measurement accuracy, and equipment longevity.

By validating and adjusting parameters such as frequency, power output, temperature accuracy, and energy uniformity, calibration ensures that every cleaning cycle delivers optimal, repeatable results. It transforms the Ultrasonic Cleaner from a simple device into a verified, dependable part of a controlled and traceable workflow—one that supports the highest standards of hygiene, safety, and precision.