Combustible Gas Detector: The Vital Tool for Safety and The Absolute Necessity of Calibration

In industrial, construction, and maintenance environments, the presence of combustible gases (such as Methane, Propane, Hydrogen, etc.) poses an ever-present threat, potentially leading to explosions, property damage, and severe injuries. The Digital Combustible Gas Detector is the primary safety tool, designed to detect and immediately warn of hazardous gas leaks before they reach dangerous concentrations (LEL – Lower Explosive Limit). This device plays a vital role in ensuring operational safety, regulatory compliance, and protecting human lives. However, because gas sensors operate continuously in harsh environments, they are susceptible to drift or poisoning, which reduces sensitivity. Therefore, routine Combustible Gas Detector Calibration is an absolute requirement to ensure the device responds accurately and reliably.

1. What is a Combustible Gas Detector? Operating Principle

A Combustible Gas Detector is a measurement and safety instrument designed to detect the presence and concentration of gases capable of causing fire or explosion. The primary goal is to provide an early warning before the gas concentration reaches a hazardous level.

1.1. Classification of Hazardous Gases (LEL and UEL)

- LEL (Lower Explosive Limit): This is the lowest concentration of gas (by volume in air) that can cause a fire or explosion if an ignition source is present.

- UEL (Upper Explosive Limit): This is the highest concentration of gas (by volume in air) that can still cause a fire or explosion.

- Role: Gas detectors are designed to measure gas concentration as a percentage of the LEL (% LEL). Alarms are typically activated at 10% LEL or 20% LEL.

1.2. Common Operating Principle (Catalytic Sensor)

Catalytic Sensor Mechanism

Detection relies on oxidation of combustible gas on a catalytic bead: oxidation → local heat rise → resistance change measured by a Wheatstone bridge.

- Structure: The sensor typically consists of two metallic coils (often Platinum) housed within a flame-arresting mesh. One coil is the active element containing a catalyst, and the other is the reference element without a catalyst.

- Detection Mechanism:

- When combustible gas enters the sensor, it oxidizes (burns) on the surface of the catalyzed active coil.

- This combustion process causes the temperature of the active coil to increase.

- The change in temperature changes the electrical resistance of the coil.

- The device measures the difference in resistance between the active and reference coils (using a Wheatstone bridge) to accurately calculate the gas concentration.

- Note: This type of sensor requires oxygen to operate and must be calibrated frequently to counteract drift and poisoning.

2. Essential Applications of Combustible Gas Detectors

Oil & Gas

Leak detection on rigs, refineries, pipelines — essential for personnel and asset protection.

Confined Spaces & HVAC

Pre-entry testing, boiler rooms, tunnels — prevents catastrophic incidents in enclosed spaces.

Environmental & Construction

Monitoring methane at landfills and excavation near buried gas lines — safety & regulatory compliance.

The ability to detect combustible gas is the foundation of safety programs across many sectors.

2.1. Oil, Gas, and Energy Industries

- Exploration and Production: Monitoring the concentration of Methane (CH4) and other Hydrocarbons at drilling rigs, refineries, and pumping stations.

- Equipment Maintenance: Checking for gas leaks in pipelines, valves, and oil/gas storage areas.

2.2. HVAC and Utility Systems

- Leak Detection: Locating leaks of natural gas in piping systems, commercial kitchens, boilers, and gas-fired equipment.

- Confined Spaces: Testing hazardous confined spaces such as tunnels, sewers, or storage bunkers before personnel entry, ensuring there is no accumulation of asphyxiating or explosive gases.

2.3. Environmental Safety and Construction

- Landfills and Waste Treatment: Monitoring Methane gas generated from the decomposition of waste materials.

- Construction: Checking excavation sites near underground gas lines to prevent explosion hazards from unexpected gas leaks.

3. Critical Technical Parameters Requiring Control

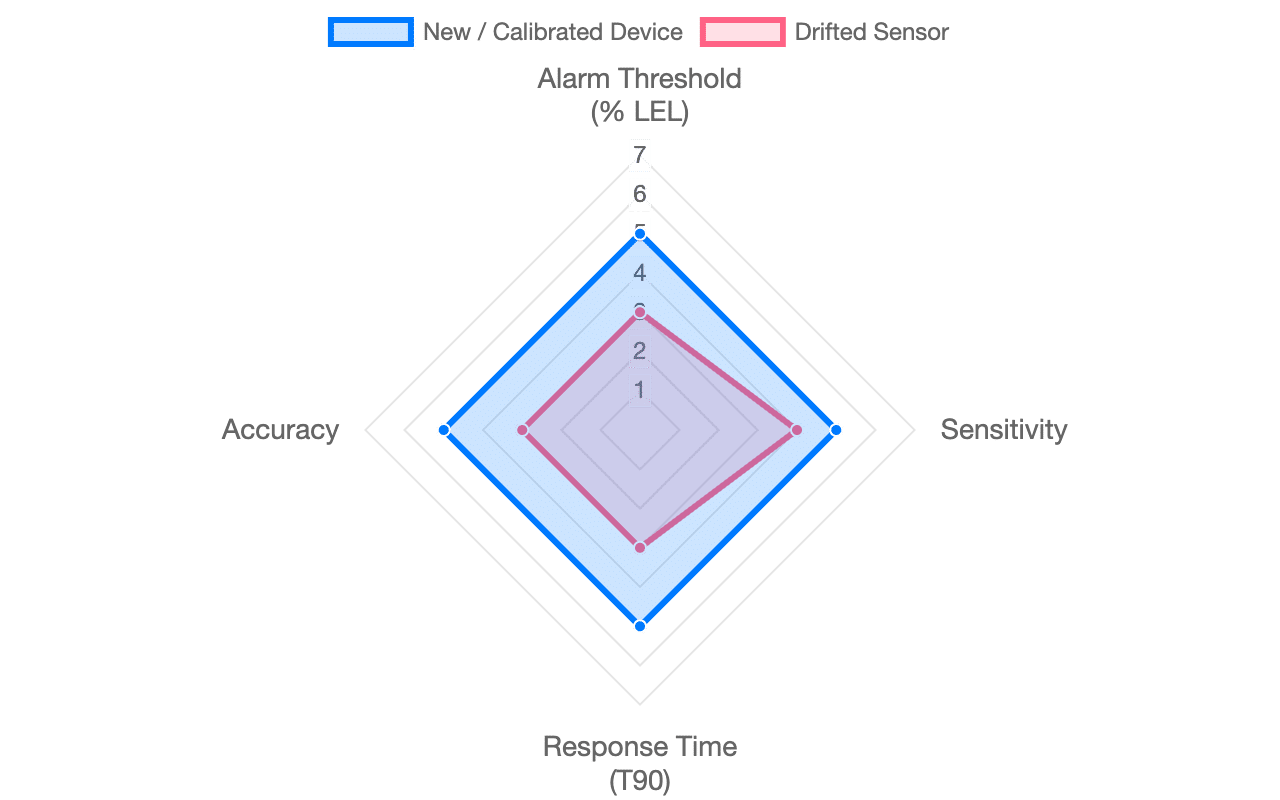

Detector performance depends on alarm thresholds, sensitivity, response time (T90) and accuracy. Below is a compact visual comparison (static) between an ideal/calibrated detector and one exhibiting drift.

Sensor Performance Evaluation (Radar Chart)

The performance of a Combustible Gas Detector relies on its sensing and data processing capabilities.

3.1. Alarm Thresholds

- LEL (Lower Explosive Limit): The device must detect gas at a concentration significantly lower than the LEL. Typically, the low-level alarm threshold is set at 10% or 20% LEL.

3.2. Sensitivity and Response Time

- Detection Capability: The device must have high sensitivity to accurately detect gas even at the lowest concentrations.

- Speed: The response time (T90) must be fast to provide an immediate warning upon gas detection.

4. Combustible Gas Detector Calibration: A Survival Requirement

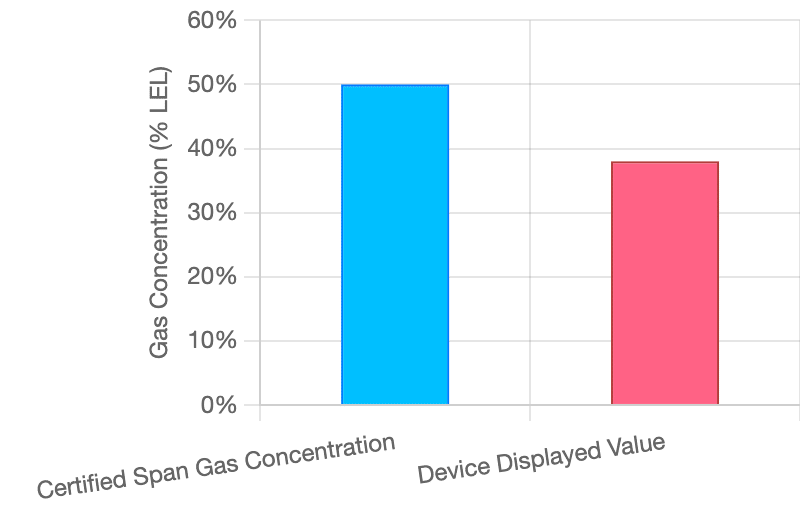

Actual vs. Displayed Value (Using Span Gas @ 50% LEL)

A detector reading 38% LEL when exposed to 50% LEL Span Gas is dangerously inaccurate and requires immediate Full Calibration.

Combustible Gas Detector Calibration is the single most important process to ensure the device actually works when needed.

4.1. Risk of Sensor Drift and Poisoning

- Sensor Drift: Over time, the performance of the gas sensor naturally degrades due to component wear, leading to inaccurate or slow readings.

- Poisoning: Continuous exposure to chemical compounds like Silicones, Sulfur, or Halogens can permanently damage the sensor surface, rendering the device incapable of detecting gas.

4.2. The Calibration Procedure (Bump Test vs. Full Calibration)

- Function Check (Bump Test): A quick daily or weekly check by briefly exposing the device to a known concentration of test gas. This check only confirms whether the device reacts.

- Full Calibration:

- Purpose: To reset the device to accurately read a known test gas concentration.

- Procedure: Using Span Gas of a traceable and certified concentration to adjust the sensor’s reading points (usually the zero point and the span point), restoring the device to its initial accuracy.

4.3. Regulatory and Legal Compliance

- Mandatory Requirement: International and local organizations (OSHA, IATA, fire safety regulations) mandate that gas detectors must be calibrated periodically (typically every 6 or 12 months) to prove the device is operating according to specifications.

- Legal Evidence: The calibration certificate is the only legal proof that a company has taken the necessary measures to protect personnel and assets.

Conclusion

The Digital Combustible Gas Detector is the first and most critical shield against industrial disaster. However, this shield is only effective when properly maintained. Combustible Gas Detector Calibration is not an optional cost; it is a mandatory investment in survival and safety. Only through routine calibration can we ensure that these devices will operate accurately and timely when human lives depend on them.