I. Introduction

Temperature measurement is one of the most fundamental parameters across countless industries—from manufacturing and HVAC to pharmaceuticals, food processing, and R&D laboratories. Yet even the most advanced thermometers can drift over time due to component aging, environmental exposure, or handling stress.

That’s why Digital Thermometer Calibration is not merely a maintenance task—it’s a quality assurance process. It ensures every temperature reading you rely on is accurate, traceable, and compliant with international standards.

II. What Is Digital Thermometer Calibration?

Digital thermometer calibration is the process of comparing the temperature readings of a thermometer under test (UUT) to those of a reference thermometer with known accuracy and traceability to a national standard—typically the National Institute of Standards and Technology (NIST).

The goal is to determine and document any deviation, adjust the instrument if necessary, and provide certification that confirms the thermometer’s accuracy and traceability.

Common calibration setups include:

-

Dry-block calibrators or liquid baths for stable temperature environments.

-

Reference thermometers (such as high-precision RTDs or thermistor probes) with ISO/IEC 17025-accredited calibration certificates.

-

Multiple temperature points—commonly 0 °C, 25 °C, 50 °C, 100 °C—to verify performance across the full operating range.

A properly calibrated digital thermometer ensures that every temperature-dependent process—whether for compliance, product quality, or safety—rests on a solid, traceable foundation.

III. Why Calibration Matters for Digital Thermometers

Temperature affects almost everything—from product consistency to energy efficiency and regulatory compliance. Even small deviations can have large impacts:

-

In HVAC systems, a ±1 °C drift can mislead performance diagnostics and increase energy costs.

-

In pharmaceutical or medical environments, inaccurate readings may compromise safety or regulatory audits.

-

In food and beverage production, temperature errors can directly affect product quality and shelf life.

Regular calibration not only corrects measurement drift but also provides proof of compliance with quality frameworks such as ISO 9001, HACCP, and GMP. It protects your operation from costly downtime, recalls, or non-conformance findings during audits.

Contact Techmaster Electronics today to discuss your digital thermometer calibration needs, or to request a quote for ISO/IEC 17025-accredited temperature services.

Calibration Triggers

Calibration isn’t a one-time task. Use these triggers to keep your instrument trustworthy.

Home Use: Every 6–12 months

IV. The Digital Thermometer Calibration Procedure

The process for calibrating a digital thermometer involves a precise series of steps designed to ensure consistency and traceability.

At Techmaster Electronics, this procedure is performed under strict ISO/IEC 17025 guidelines using reference standards traceable to NIST.

-

Preparation

-

Verify instrument condition and battery health.

-

Identify measurement range and required temperature points.

-

Set up reference equipment and calibration environment (dry-block or liquid bath).

-

-

Stabilization

-

Allow both the thermometer under test (UUT) and the reference thermometer to stabilize at each test temperature.

-

Environmental factors like humidity, airflow, and ambient temperature are controlled according to ISO 17025 requirements.

-

-

Comparison

-

Record readings of the UUT and the reference thermometer simultaneously.

-

Calculate the deviation (UUT – Reference) at each temperature point.

-

-

Adjustment (if applicable)

-

Apply corrections or software adjustments when permissible to bring readings within tolerance.

-

-

Data Analysis and Reporting

-

Evaluate deviations, apply measurement uncertainties, and prepare a full calibration data report.

-

Under ISO/IEC 17025, each value includes an expanded uncertainty (typically k = 2).

-

-

Certification

-

Issue an official calibration certificate bearing the ANAB accreditation mark and Techmaster’s certificate number, signifying that the work was performed under accredited scope.

-

The report includes: traceability to NIST, calibration date, measurement uncertainty, and the applied decision rule (ILAC-G8:2019).

-

The How-To: Two Simple, Reliable Methods

Method 1: The Ice Point (0°C / 32°F)

A properly made ice bath holds a stable 0 °C reference.

- Fill a glass with crushed ice.

- Add just enough cold water to make a slurry.

- Submerge the probe ~30 s, stir gently.

- Reading should be exactly 0 °C (32 °F).

- If not, adjust or note the offset.

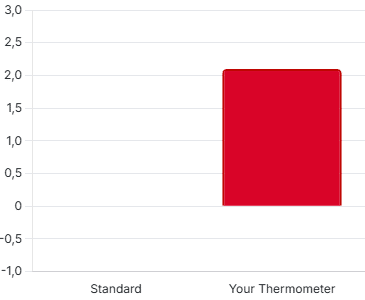

The chart below shows how a drifted thermometer’s reading compares to the known standard in an ice bath test.

Method 2: The Boiling Point

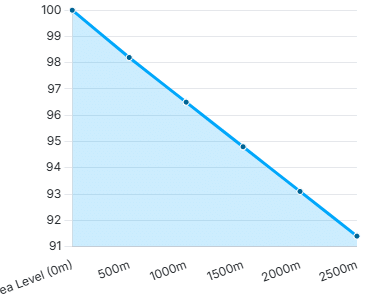

Boiling point drops with altitude—100 °C applies at sea level only.

- Look up boiling point for your altitude.

- Bring purified water to a rolling boil.

- Submerge the probe, avoid pot sides.

- Reading should match your altitude’s boiling point.

- Adjust or note the offset if needed.

This chart illustrates the direct relationship between increasing altitude and the decreasing boiling point of water.

V. Case Study: Cooper-Atkins SH66A

To illustrate the process, let’s consider the Cooper-Atkins SH66A, a three-channel thermistor-based digital thermometer widely used in HVAC and refrigeration diagnostics.

During calibration:

-

Each channel was tested at multiple points (0 °C / 25 °C / 50 °C / 100 °C) using a multi-well dry-block calibrator and a reference thermometer with ±0.05 °C accuracy.

-

Deviations were within ±0.2 °C across all channels—fully compliant with ISO/IEC 17025 requirements.

-

The final calibration certificate documented the results, uncertainty, and NIST traceability chain.

This demonstrates how regular calibration ensures that even multi-channel instruments maintain reliable, synchronized temperature readings—vital for accurate HVAC system balancing and energy efficiency diagnostics.

Professional vs. DIY Calibration

DIY checks are helpful, but regulated industries need certified accuracy. A NIST-traceable calibration provides defensible proof against national standards.

| Feature | DIY (Ice/Boil) | Professional (NIST-Traceable) |

|---|---|---|

| Best For | Home cooks, routine checks, non-critical tasks. | Regulated industries, labs, quality control. |

| Accuracy | Good for major drift (≈ ±1 °C). | Highest, with quantified uncertainty. |

| Cost | Free. | Service fee per instrument. |

| Documentation | None. | Official Certificate of Calibration. |

VI. Techmaster’s Calibration Capabilities and Standards

Techmaster Electronics operates one of the most comprehensive calibration networks in the United States—with laboratories in Vista (CA), Fremont (CA), Orlando (FL), and San Antonio (TX), along with accredited international facilities in Mexico, Thailand, and Vietnam.

Broad Multidisciplinary Expertise

Techmaster’s accredited scope covers more than ten measurement disciplines, including:

-

Thermodynamic (Temperature & Humidity) – for thermometers, chambers, and ovens.

-

Electrical & RF/Microwave – for multimeters, power sources, and analyzers.

-

Dimensional / Mass / Pressure / Torque – for calipers, scales, and gauges.

Commitment to Standards

Every calibration performed by Techmaster is:

-

ISO/IEC 17025:2017 accredited by ANAB, an ILAC MRA signatory, ensuring global recognition.

-

ANSI/NCSL Z540.1 compliant, addressing U.S. aerospace and defense requirements.

-

Fully traceable to NIST or other recognized National Metrology Institutes.

Techmaster’s service structure offers three calibration levels—Commercial, Z540.1, and ISO/IEC 17025—so clients can choose the documentation depth appropriate for their quality system.

In short, Techmaster delivers metrological precision, speed, and confidence—supported by more than 30 years of calibration expertise.

VII. Recommended Calibration Frequency

The ideal calibration interval depends on the thermometer’s use, environment, and internal quality requirements.

-

Standard laboratory or indoor applications: every 12 months.

-

Field / HVAC / industrial environments: every 6 months due to temperature cycling and vibration exposure.

-

Critical or regulated processes (pharma, medical, aerospace): follow ISO 17025 risk-based intervals or customer SOPs.

Regular recalibration prevents drift accumulation, ensures data integrity, and maintains traceability throughout your measurement chain.

VIII. Choosing a Calibration Provider

Selecting the right calibration partner is as important as the calibration itself. Consider these factors:

-

Accreditation & Recognition

-

Verify that the lab is accredited to ISO/IEC 17025 by an ILAC MRA-recognized body (e.g., ANAB).

-

Ensure the provider’s scope includes temperature and thermistor thermometers.

-

-

Traceability & Transparency

-

Certificates should reference NIST or equivalent national standards.

-

Reports must include calibration data and measurement uncertainties.

-

-

Convenience & Support

-

Ask about on-site calibration, pickup/delivery options, and digital access to certificates.

-

Techmaster Electronics excels in all three areas—offering nationwide lab coverage, accredited on-site services, and a secure Techmaster Portal for 24/7 certificate access, equipment tracking, and automatic recall notification.