Smart EVs: Overcoming ‘Range Anxiety’ and ‘Fire Risk’ with Sensor Calibration

The electric vehicle (EV) revolution is changing how we get around. These days, drivers have two big fears: “range anxiety” and “fire risk.” The industry needs smarter solutions to solve these problems. That solution is EV sensor calibration. This critical but often overlooked process is the very foundation for a vehicle’s safety, performance, and the trust drivers place in them.

EV Sensors Are More Than a Measurement Tool

A modern EV is more than a car. It’s a complex, interconnected data ecosystem. Manufacturers integrate hundreds of sensors throughout the vehicle. These sensors act as the car’s nervous system. They help the car understand and react to everything from road conditions to the state of its own parts. Most importantly, these sensors are the “eyes and ears” for the Battery Management System (BMS). The BMS is a sophisticated computer that controls and protects the car’s most important asset—the battery pack.

The BMS makes decisions. It needs data from sensors to do so. Wrong information from a sensor leads to flawed decisions. Calibration ensures that every piece of data is accurate and dependable. It allows the BMS to take complete and precise control of critical battery parameters. These include voltage, current, and temperature. They are essential for both safety and performance.

Solving Big Problems: Range Anxiety and Fire Risk

The two biggest fears for EV drivers come from one place: a lack of confidence in the data. Calibration is the key to solving both problems.

1. Overcoming ‘Range Anxiety’

Few things are worse for an EV driver than when the dashboard shows a comfortable 10% battery, but the car suddenly loses power. This problem often happens when uncalibrated voltage sensors cause the BMS to wrongly calculate the State of Charge (SoC). This is not just a simple mistake. It is a fundamental failure. A miscalibrated sensor can create a large difference between the displayed range and the actual remaining power. This can affect the car’s trip planning software and charging advice. It leaves the driver stranded. On the other hand, a precisely calibrated sensor gives the BMS a single source of truth for the battery’s real capacity. This gives the driver peace of mind. They can plan longer journeys with confidence.

2. Putting Out the ‘Fire Risk’

Battery fires, while rare, are a major public concern. They often result from a process called thermal runaway. A charging fault or a critical internal battery issue can cause it. For this reason, temperature and current sensor calibration is the first and most critical line of defense. If a temperature sensor is off by even a single degree, the BMS might not detect an overheating part. It will then fail to activate the cooling system in time. Similarly, a miscalibrated current sensor can allow for an unsafe charging rate. This leads to cell damage. In contrast, a calibrated system ensures the BMS gets perfect data. It can act instantly to prevent a catastrophic event.

Calibration: The Foundation for AI and Big Data

In the future of EVs, we will use data for more than just immediate decisions. We will also use it for long-term prediction and optimization. This is where calibration becomes a key factor for the hottest new technologies.

- Machine Learning & Predictive Battery Health: Manufacturers use huge datasets from their fleets to build complex machine learning models. These models predict a battery’s “health” (SoH). They help the company know when a battery needs service or replacement. The models’ success depends on the quality of their training data. As the saying goes, “garbage in, garbage out.” Calibrated sensor data gives these models a solid base. They can then accurately predict a battery’s end-of-life years in advance.

- Optimizing Fast Charging & Vehicle-to-Grid (V2G): The pursuit of faster charging is a top goal for the industry. A perfectly calibrated sensor system makes this possible. The system can dynamically adjust charging parameters—voltage, current, and temperature—in real time. This prevents damage to the cells. Furthermore, technologies like V2G allow EVs to send power back to the grid. They also depend on highly accurate sensor data to manage the complex, two-way energy flow.

Life Cycle Calibration: From Production to Reuse

EV Battery Lifecycle

From Manufacturing Calibration to Circular Economy

Phase 1: Manufacturing & Quality Calibration

Before hitting the road, every battery must undergo rigorous testing according to global standards to ensure maximum safety and performance. This process is the foundation for a durable lifecycle.

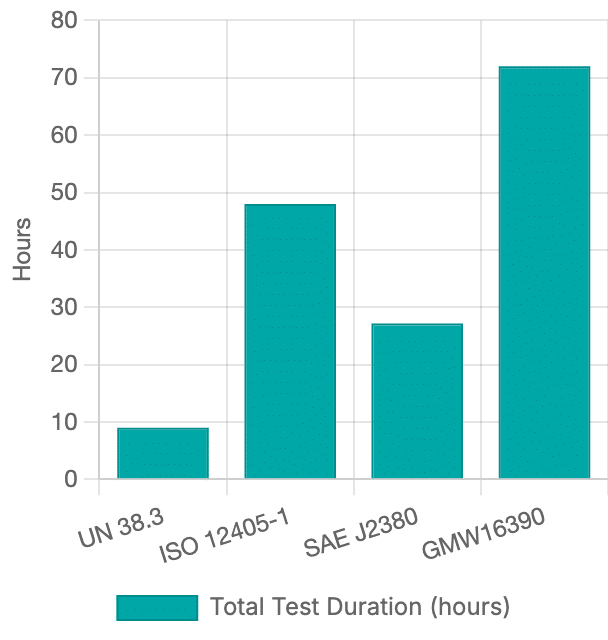

Vibration Test Duration (Hours)

Different standards require varying durability test durations. For instance, the GMW16390 standard requires a total vibration test time of up to 72 hours, significantly higher than UN 38.3, indicating its strictness in ensuring the battery’s stable operation on any road.

Key Testing Categories

Simulates real-world operating conditions: vibration, shock, temperature, and humidity to ensure stable battery structure.

🔥 Safety & Abuse

Tests dangerous scenarios: short circuits, overcharging/discharging, impacts, and fire resistance to protect users.

Precisely measures dimensions and shape to ensure a perfect physical protective layer against external factors.

Phase 2: Operation & Lifecycle Optimization

Battery life depends not only on manufacturing quality but also on how we use them. Good habits and software technology significantly help extend the battery’s lifecycle.

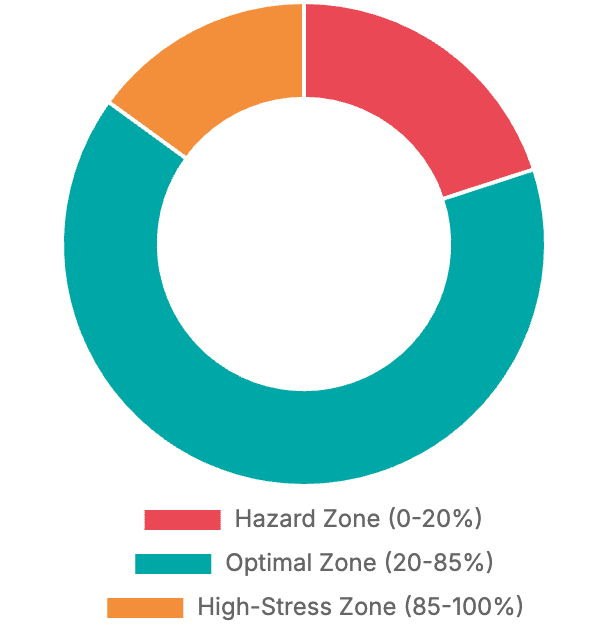

Optimal Charging Zone

Experts recommend maintaining the battery charge level between 20% and 85% to optimize its lifespan. Regularly charging to 100% or letting it drain to 0% puts stress on the battery cells, leading to faster degradation.

Key Influencing Factors

- 🌡️ Temperature

- Both excessively high and low temperatures reduce battery life. Avoid parking under direct sunlight.

- ⚡ Charging

- Limit frequent use of fast chargers. Slow charging overnight at home is the best option for the battery.

- 🚗 Driving Style

- Sudden acceleration and hard braking put great stress on the battery, reducing its performance and lifespan.

- 🔄 Software Updates

- Manufacturers can “recalibrate” the battery remotely, improving performance and fixing bugs through over-the-air updates.

Phase 3: End-of-Life & Circular Economy

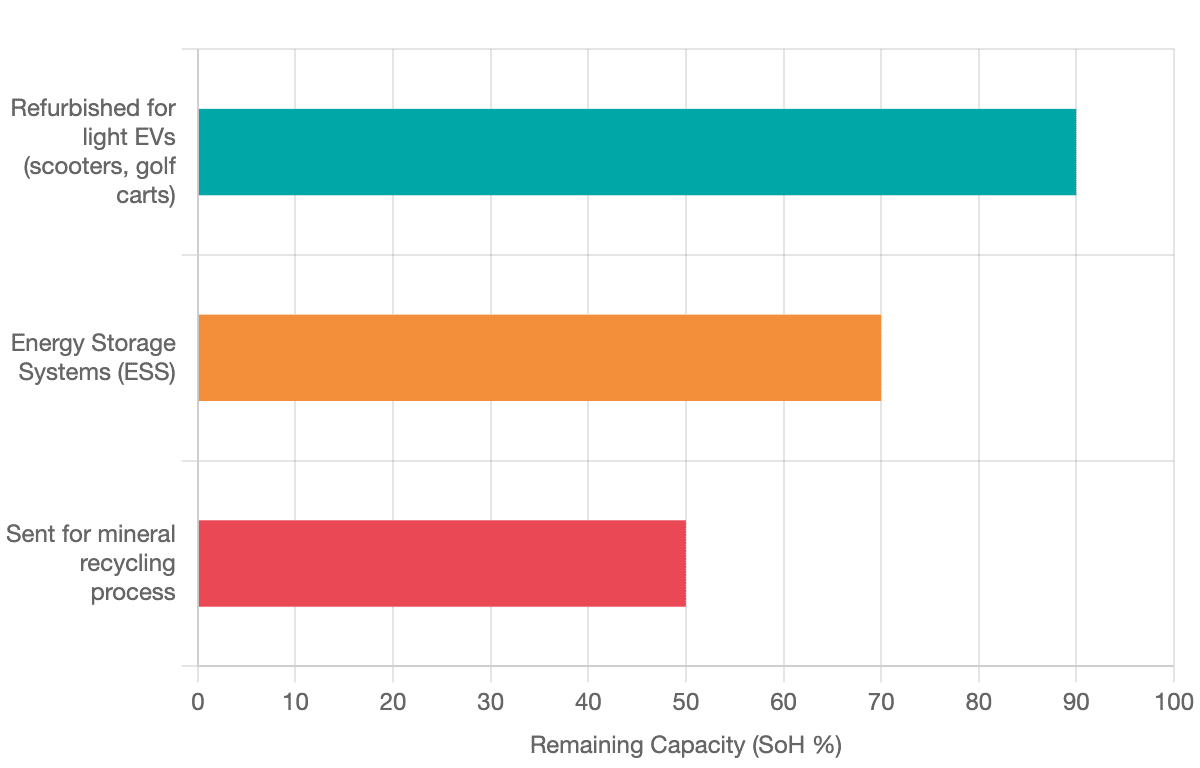

When a battery is no longer suitable for EVs (typically below 80% of its original capacity), it begins a “second life” or is recycled, closing the circular economy loop.

Battery Reuse Classification

Accurately assessing the State of Health (SoH) of a battery is key to determining its value and finding a suitable application in its “second life,” maximizing asset value and minimizing waste.

Battery Recycling Technologies

✅ Simple, easy to implement❌ Energy-intensive; Produces toxic emissions; Loses important minerals

✅ High recovery efficiency; Less emissions

❌ Complex process; Requires chemical and wastewater treatment

✅ Energy-efficient; Preserves material structure

❌ Requires advanced technology; Not yet widely adopted

Calibration is not a one-time process. It is a critical part of a vehicle’s entire life cycle.

- During Production: Manufacturers calibrate each sensor initially with precision equipment. This first step ensures that every car leaving the factory is safe and reliable. The process includes a series of careful checks. They guarantee the data stream’s integrity.

- Periodic Maintenance: A sensor’s accuracy can change over time. Minor accidents, part aging, or exposure to extreme temperatures can cause this. Periodic calibration during scheduled service checks is essential. It helps maintain the car’s safety and performance over its lifespan.

- Battery Reuse: When an EV battery reaches the end of its first life, it can still have up to 80% of its power left. Calibrated sensor data is vital for a correct evaluation of a used battery’s condition. This information helps us create a “digital twin” of its health. This digital twin is essential for repurposing the battery for a second life. A good example is using it in a grid-level energy storage system. This helps create a circular economy.

Conclusion

In the end, sensor calibration is not a boring technical procedure. It is a core part of what makes an EV truly safe, smart, and efficient. It turns raw data into driver confidence. By prioritizing calibration, manufacturers not only meet strict rules but also build trust with their customers. From making every trip accurate to protecting against major risks, calibration is the key. It unlocks the true potential of electric vehicles. It helps drive the industry forward.