Ice Point Reference: The Foundation of Temperature Accuracy and the Role in Ice Point Reference Calibration

In temperature measurement, the Freezing Point of Water (0∘C or 32∘F) serves as a fundamental reference point. To achieve the highest accuracy for this benchmark in labs and industry, professionals use an Ice Point Reference device. This instrument creates and maintains an extremely stable temperature environment at 0∘C, thus eliminating the need for traditional crushed ice. Furthermore, the Ice Point Reference device forms the foundation for broader Temperature Calibration. However, the reliability of the reference point itself is also critical. Therefore, Ice Point Reference Calibration plays a crucial role. It ensures this foundational device consistently provides the most accurate 0∘C point, allowing all temperature sensors (like thermocouples and RTDs) to be accurately checked.

1. What is an Ice Point Reference?

An Ice Point Reference device is a specialized instrument. Manufacturers design it to create and maintain a precisely stable temperature environment at 0∘C (32∘F). This device simulates the freezing point of pure distilled water, but it offers superior stability and accuracy compared to manual crushed ice.

1.1. Typical Operating Mechanism:

Most modern ice point reference devices operate using the Peltier effect or other semiconductor cooling systems.

- Creating and Maintaining the 0∘C Point: The device uses a chilled and continuously stirred water chamber. This action creates a dynamic equilibrium between the liquid (water) and solid (ice) phases.

- Electronic Control: An electronic temperature controller (often a PID controller) monitors the internal temperature. It then adjusts the cooling process to ensure the temperature stays at 0∘C with very small error (typically only a few thousandths of a degree Celsius).

- Thermowells: Inside the device are hollow wells. Users can immerse the temperature sensor probes (thermocouples, RTDs, thermistors) needing calibration into these wells. These wells are surrounded by the stable 0∘C environment, ensuring full sensor contact with the reference temperature.

1.2. Importance:

An Ice Point Reference device serves as a fixed reference point. It provides a reliable “zero point” for checking and adjusting temperature sensor accuracy. This is crucial in high-precision applications, where even small errors can greatly impact results.

2. Core Applications of an Ice Point Reference

The Ice Point Reference device is an essential tool in calibration laboratories, quality control departments, and scientific research.

Thermocouple Calibration

Provides a stable Cold Junction Reference (CJR) at 0°C, ensuring absolute measurement accuracy.

RTD Sensor Verification

Tests and verifies the accuracy of RTD sensors and thermometers at the 0°C standard.

Routine/Daily Checks

Performs quick daily checks in the lab to detect early drift in measuring devices.

2.1. Temperature Sensor Calibration

This is its primary and most important application:

- Fundamental Reference Point: It provides a precise 0∘C reference environment. This check is mandatory for most temperature sensors, especially those used in cold and moderate temperature ranges.

- Thermocouple Calibration: It offers an ideal and stable cold junction for thermocouple measurements. Thermocouples measure temperature differences. Specifically, they measure the difference between a hot and a cold junction. This device holds the cold junction precisely at 0∘C, eliminating reference errors. Consequently, it allows for accurate hot junction temperature calculations.

- RTD and Thermistor Testing: Technicians use it to verify the 0∘C point of RTDs and Thermistors. This ensures they respond correctly to their established characteristics.

2.2. Applications in Scientific Research and Testing

- Absolute Stability: In experiments demanding absolutely precise reference temperature maintenance for hours or days, this device replaces continuous manual ice replacement.

- Instrument Verification: Scientists use it as a standard source to quickly check the accuracy of other temperature measuring devices. These include digital thermometers or temperature data loggers.

3. Superiority Over Traditional Ice Baths

Traditional methods use crushed ice and distilled water. However, the Ice Point Reference device offers superior accuracy and convenience.

3.1. Higher Accuracy and Long-Term Stability

- Eliminates Manual Errors: Ordinary crushed ice can introduce errors if not stirred consistently. Errors also occur if the ice is not pure distilled water, or due to trapped air. The reference device creates a more uniform and pure environment.

- Automatic Maintenance: The device uses electronic controls (often Peltier-based). These automatically create and maintain equilibrium between water and ice. It holds the temperature at 0∘C ±0.005∘C (or better) for extended periods, often 24/7.

3.2. Convenience and Cost-Effectiveness

- Reduced Operating Costs: It eliminates the need for continuous purchasing, crushing, and preparing pure ice. Users simply connect it to power for operation.

- Increased Productivity: It saves manual preparation and monitoring time. This allows calibration technicians to focus on more complex measurement tasks.

4. The Critical Role of Ice Point Reference Calibration

The accuracy of the entire temperature measurement process depends on the 0∘C point used. Thus, the reliability of the Ice Point Reference device itself is paramount.

- Foundation of Traceability: Using a verified (or calibrated) Ice Point Reference is a prerequisite. This ensures your temperature measurements are traceable to national (e.g., NIST) or international (SI units) standards. The reference device itself must meet these standards.

- Ensuring Product Quality: In industries like pharmaceuticals, food, or chemicals, a small error at 0∘C can skew the entire measurement range. A properly calibrated reference device guarantees the measurement system remains unaffected by this fundamental error.

- Verifying Device Performance: Over time, even high-precision devices can drift. Periodic calibration of the Ice Point Reference confirms its continued ability to maintain 0∘C with the specified accuracy.

Why ‘Calibrate’ a Physical Constant?

The 0°C point is only theoretical. In practice, factors like water purity and preparation technique can cause severe errors. ‘Calibration’ here is the process of controlling these factors.

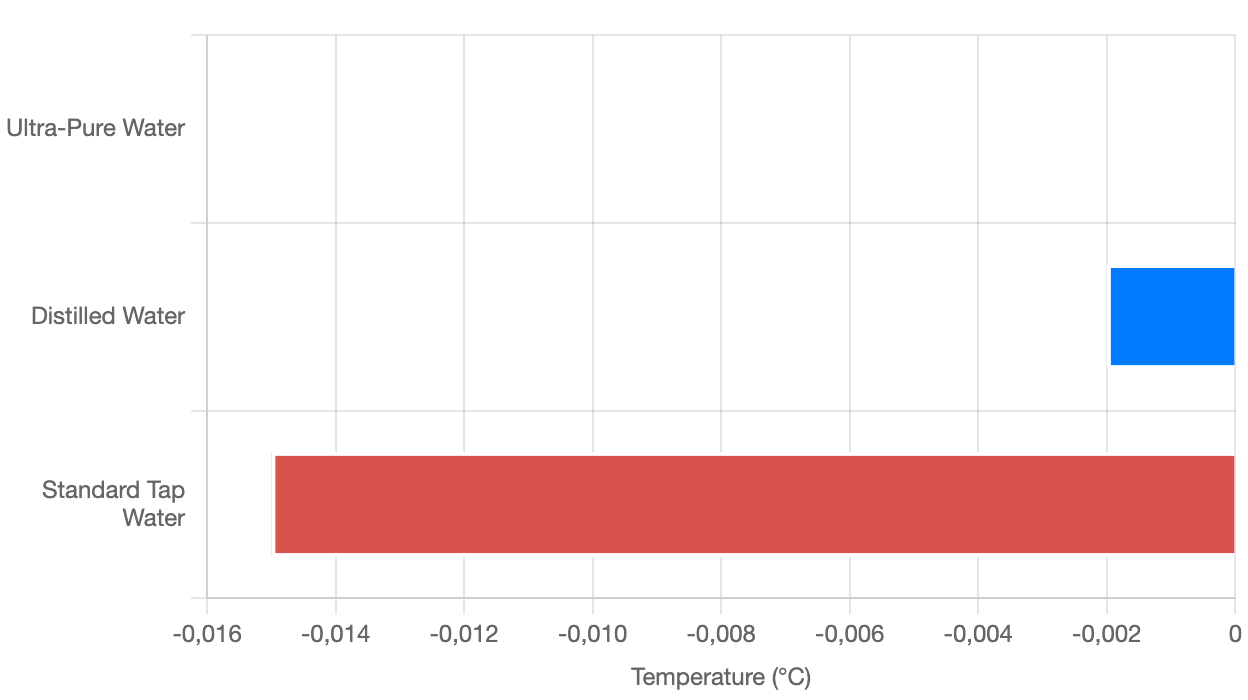

Impact of Water Purity

Comparison of actual freezing points for different water types.

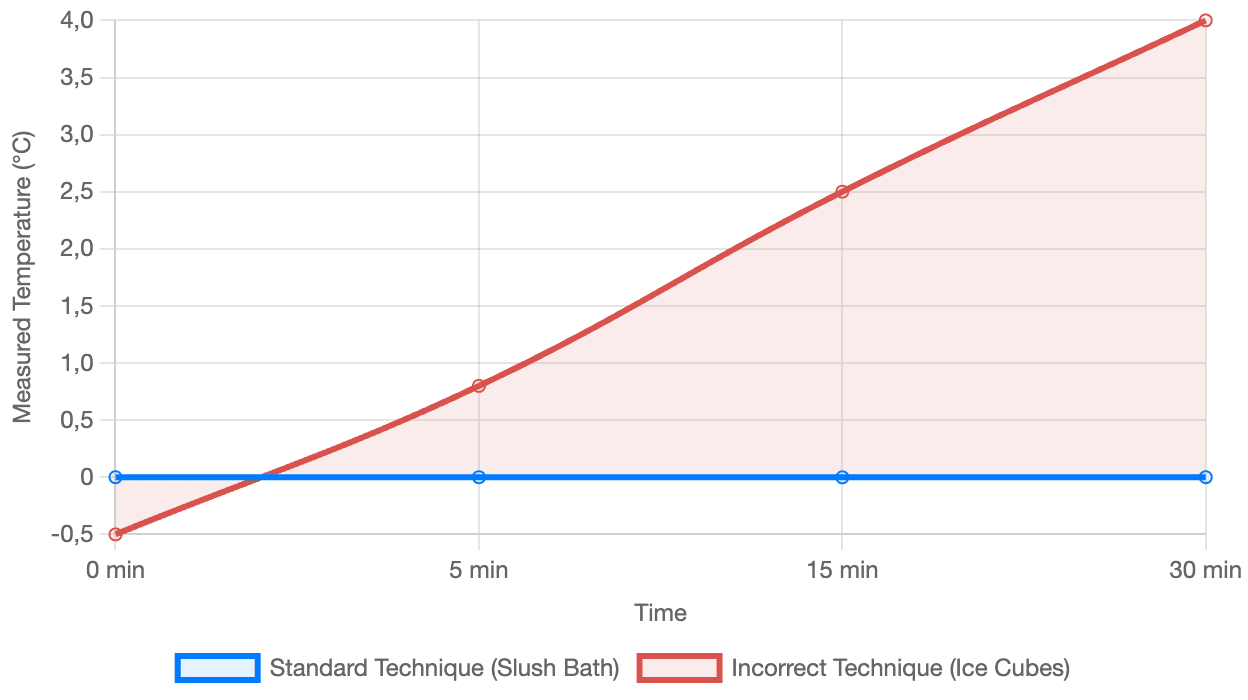

Temperature Stability by Technique

Correct “slush bath” technique maintains stable temperature, unlike common ice cubes.

Precise 0°C Reference Preparation Procedure

Sensor Calibration Frequency

The official calibration cycle (Calibration Interval) differs from the quick 0°C check (Ice Point Check).

MONTHS (STANDARD)

For stable operation and normal environment. Default interval.

MONTHS (STRICT)

Applied to harsh environments, large temperature swings, high-risk processes.

ICE POINT CHECK

Mandatory before every critical measurement session to quickly detect sensor drift.

Conclusion

The Ice Point Reference device is an indispensable tool in any professional temperature calibration laboratory. It provides quantitative certainty at the most fundamental reference point, 0∘C. Moreover, the calibration of the Ice Point Reference itself is crucial. It ensures this foundational device consistently performs to its highest standards. By eliminating the uncertainties and inconveniences of manual ice baths, this device (when calibrated) ensures the highest accuracy, efficiency, and standard compliance for all temperature measurements. Therefore, investing in a reliable and calibrated reference device means investing in the quality and integrity of temperature data.