Why Semiconductor Parameter Analyzer Calibration Matters

You may be characterising transistors, diodes or entire integrated circuits. To do this accurately, you rely on a semiconductor parameter analyzer. It delivers precise voltage–current curves, capacitance plots and switching characteristics. These instruments are also called semiconductor device analyzers or SMU analyzer systems. They combine multiple source‑measure units (SMUs) with switching matrices. This setup performs low‑current measurements across many orders of magnitude. Their capabilities come at a price. Drift or misalignment in a voltage reference or sense amplifier can cause significant errors in threshold voltage or leakage current readings. That is why semiconductor parameter analyzer calibration is not merely a checklist item. It is an essential maintenance practice. Proper calibration protects your research investment, production yield and customer confidence.

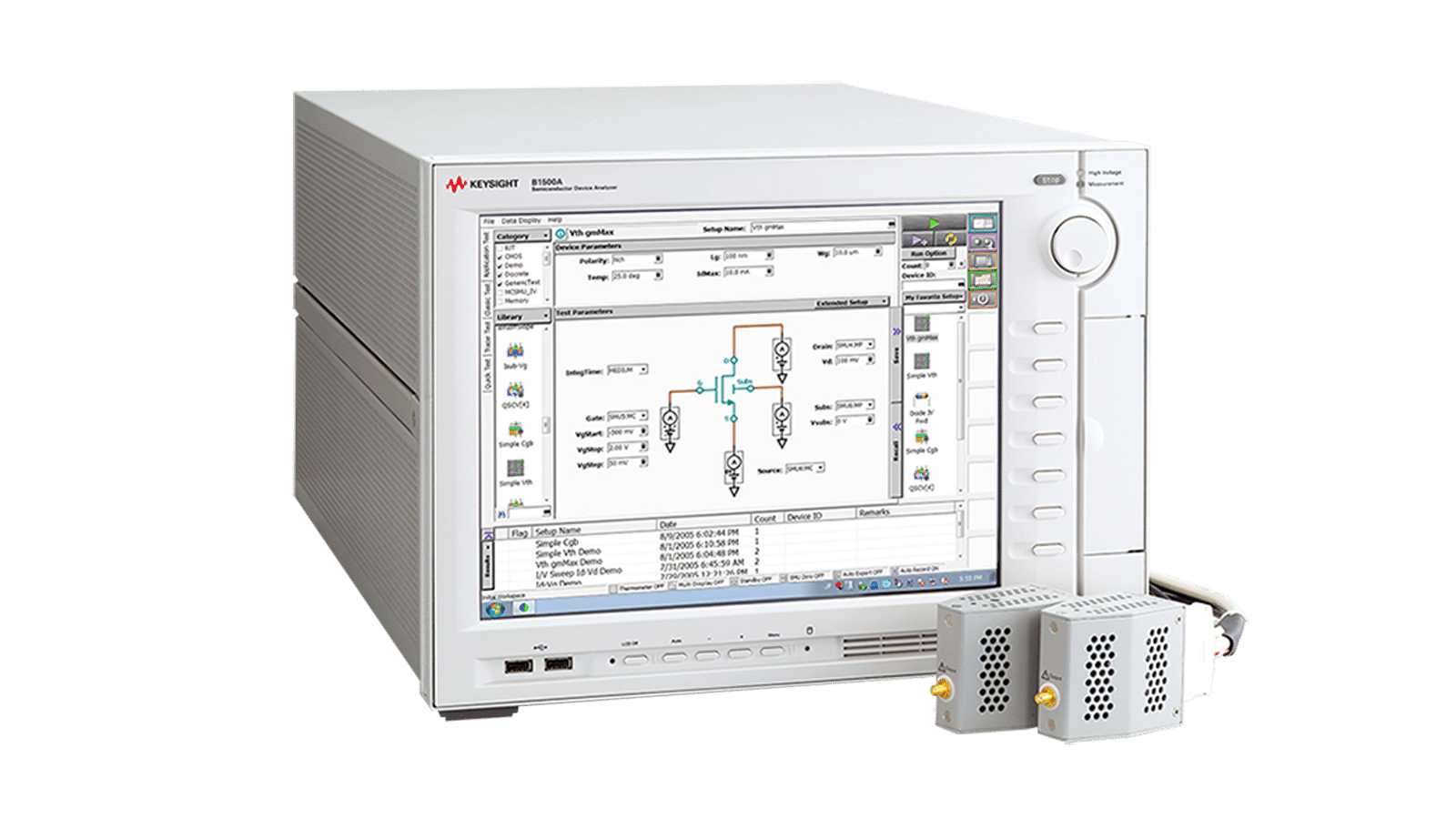

In precision measurement work, calibration compares an instrument against a reference standard with known accuracy. For parameter analyzers, this means verifying that each SMU can source and measure voltage and current within specified tolerances. Modern analyzers, such as Keysight’s B1500A or B1505A series, include an auto‑calibration routine that periodically compensates for temperature drift. However, self‑calibration does not replace a full laboratory calibration. It only aligns internal modules relative to their own reference standards. Regular external calibration by a competent laboratory keeps the analyzer’s readings traceable to national standards. It also helps meet regulatory requirements.

Understanding Semiconductor Device Analyzer Calibration Needs

A semiconductor parameter analyzer has several SMUs that can source and measure voltage and current. It may also include optional capacitance measurement units (CMUs) and switching modules. Engineers use these instruments to perform IV and CV characterisation of devices. They work from a few millivolts up to hundreds or even thousands of volts. Because the analyzer covers a wide dynamic range, the calibration process must verify many ranges and functions. For example, the B1500A offers current ranges down to femtoampere levels. It also provides voltage ranges up to 200 V or more. Each range requires its own calibration constants. Drift in the low‑current preamplifier can have a large impact on leakage measurements.

Manufacturers incorporate internal calibration capabilities to improve stability between lab calibrations. For example, the B1500A allows users to enable auto‑calibration. When the system is idle, it recalibrates its SMU modules every 30 minutes. This routine improves repeatability by compensating for thermal changes. However, it relies on the instrument’s internal reference standards. Internal standards can drift over time. Therefore, industry best practices recommend annual or semi‑annual external calibration by an accredited laboratory. Accredited labs use reference standards traceable to national metrology institutes such as the NIST in the United States. They also report measurement uncertainty. This gives you quantitative confidence in your analyzer’s performance.

How Parameter Analyzer Calibration Protects Your Measurements

Drift occurs because electronic components age and environmental conditions vary. A small change in the reference voltage used by an SMU can bias an entire sweep of data. This misrepresents the threshold voltage or subthreshold slope of your device. Similarly, contamination on probe tips or connectors can increase contact resistance and lead to current measurement offsets. Regular calibration and maintenance detect these issues before they affect critical measurements.

A thorough calibration includes:

-

Visual inspection and cleaning – The technician ensures that connectors are free from debris and that cables and probes are intact. Even tiny amounts of contamination at the low‑current levels measured by a parameter analyzer can introduce significant offsets.

-

Functional verification – Each SMU and measurement channel is exercised across its full range. Source and measurement accuracy, linearity and noise performance are evaluated using precision reference sources and load resistors.

-

Adjustment – If a range fails to meet specifications, the lab can adjust calibration constants if allowed by the manufacturer. If that is not possible, the lab will flag the instrument for repair.

-

Documentation – A calibration certificate details the results, including measurement uncertainties and traceability information. For accredited calibrations, the certificate will reference ISO/IEC 17025 requirements and list all reference standards used.

By following this process, your analyzer returns to specification. It also provides an auditable record that your measurements are trustworthy. The result gives engineers confidence in device characterisation. Quality managers will find it satisfies ISO 9001, IATF 16949 or aerospace requirements. Procurement and regulatory teams gain documentation that demonstrates due diligence.

Choosing the Right Calibration Provider

Selecting a calibration provider for a high‑end parameter analyzer is more than a transactional decision. You need a partner that understands the intricacies of semiconductor test equipment. When evaluating providers, consider the following:

-

Accreditation and traceability – Make sure the lab has ISO/IEC 17025 accreditation. Also check that it offers ANSI/NCSL Z540.1 calibrations if your industry requires them. Accredited labs maintain an unbroken chain of traceability to national standards. Without proper accreditation, you may receive a certificate that auditors or customers will not accept.

-

Measurement uncertainty and scope – Ask for the lab’s scope of accreditation. Verify that it covers the voltage, current and frequency ranges of your analyzer. High‑precision SMU ranges may require uncertainties in the microvolt per volt or picoampere per ampere region. Not all labs can achieve this. Compare the lab’s test uncertainty ratio (TUR) to your instrument’s specifications. A typical rule of thumb is a minimum 4:1 ratio. This means the lab’s standard is at least four times more accurate than the device being calibrated.

-

Service options – Look for providers that can calibrate on‑site to minimise downtime or offer expedited turnaround. Some labs also provide pick‑up and delivery services or ship replacement units while yours is in the lab.

-

Repair and rental capability – If your analyzer is found out of tolerance, the ability to repair it quickly prevents extended downtime. Rental or loaner equipment keeps your workflow running while your unit is being serviced.

-

Documentation and support – Modern labs offer digital portals to retrieve certificates, recall notices and service history. These portals simplify audits and help quality managers maintain calibration schedules.

Spotlight on Techmaster Electronics: Semiconductor Device Analyzer Calibration Services

Techmaster Electronics meets these criteria. The company has more than 30 years of experience in test equipment services. It combines calibration, repair and rental under one roof. This provides a holistic lifecycle solution for your instrument fleet. Techmaster emphasises ISO/IEC 17025 accreditation and NIST traceability in all service levels. This ranges from basic commercial certificates to Z540.1 and fully accredited calibrations that include expanded uncertainty statements. We highlight a minimum 4:1 test uncertainty ratio for calibrations. This ensures that their reference standards exceed the accuracy of the devices we service.

Techmaster calibrates both the parameter analyzers themselves and the calibrators used to check them. For example, we service multi‑function calibrators like the Fluke 5500/5520/5730 series and voltage/current calibrators. We also handle AC voltage calibrators such as the Fluke 9500X. By maintaining these standards, we can provide accurate SMU analyzer calibration. This supports instruments like the Keysight B1500A.

Our network of accredited labs spans North America and Asia. Facilities are located in California, Florida, Mexico, Thailand and Vietnam. We also offer on‑site calibration services with quick turnaround times. Clients can access certificates and schedule recalls through an online portal. This reinforces transparency and compliance.

Calibration Intervals and Auto‑Calibration Features

Several factors determine how often to calibrate a semiconductor parameter analyzer. These include how critical the measurements are, how often the instrument is used and the environment in which it operates. The common practice is to calibrate annually. High‑precision or high‑use laboratories may choose a six‑month interval. Some quality systems require more frequent calibration when measurement data directly affect product acceptance criteria.

The auto‑calibration feature in analyzers like the Keysight B1500A runs automatically at set intervals. For example, every 30 minutes it compensates for temperature‑related drift. Engineers should enable this feature during long measurements or when working at the limits of the instrument’s range. However, auto‑calibration does not replace external calibration for two reasons:

-

Internal reference drift – Auto‑calibration uses internal reference sources that slowly drift over months or years. Without external comparison, these internal references may accumulate error.

-

Compliance and traceability – External calibration provides documentation that an independent lab verified the instrument against traceable standards. Auto‑calibration alone cannot satisfy ISO 9001 or regulatory requirements.

Therefore, treat auto‑calibration as a short‑term stability aid. Maintain a regular schedule with an accredited laboratory for full calibration.

Establishing a clear semiconductor parameter analyzer calibration interval helps maintain data integrity and compliance.

Preparing Your Parameter Analyzer for Calibration and Maximising Uptime

As an engineer or technician, you can help the calibration process run smoothly and protect your analyzer by following these best practices:

-

Warm‑up – Turn on the analyzer at least one hour before performing critical measurements or sending it for calibration. Many semiconductor parameter analyzers require a warm‑up period to stabilise internal references.

-

Perform self‑tests – Most analyzers include built‑in self‑test routines. Running these tests prior to sending the unit for calibration can help identify obvious faults and reduce the chance of an unexpected failure during calibration.

-

Document symptoms – If you have noticed measurement anomalies, note them for the calibration laboratory. Providing this information helps technicians focus on problematic ranges and reduces diagnostic time.

-

Back up software and test setups – Calibration may reset internal settings. Back up any custom scripts, test sequences or limit files to ensure you can restore them after service.

-

Check accessories – Send along fixtures, cables or probes that are integral to your measurement setup. These accessories can be a source of error and may need cleaning or verification.

By proactively preparing, you minimise downtime and ensure that the calibration lab can return your analyzer promptly.

Building Confidence Through Service Quality

Regardless of your role, the underlying goal of calibration is confidence. A calibrated semiconductor parameter analyzer gives you confidence in your data. It underpins your research, product decisions and compliance reports. Partnering with a reputable service provider amplifies that confidence. Techmaster Electronics emphasises accredited calibration, repair capabilities and customer service. This positions it as a trusted partner for industries ranging from consumer electronics to aerospace. Their multi‑level calibration options include Commercial, Z540.1 and ISO 17025. These options allow companies to choose the appropriate level of documentation and uncertainty. Consistent NIST traceability ensures a solid metrological foundation.

Calibration also brings peace of mind. That step reduces the risk of product failures that stem from erroneous measurements. Proper calibration protects your investment in expensive wafers and devices. Additionally, it supports claims of quality in customer audits. Semiconductor technology operates at nanometre scales and microampere currents. In this context, you cannot treat measurement uncertainty as an afterthought. A robust calibration program maintains the integrity of your data and the reputation of your organisation.

Conclusion

Semiconductor parameter analyzer calibration is not a one‑time event but an ongoing discipline. Whether you are an engineer debugging a new semiconductor process, a quality manager ensuring compliance or a student learning about instrumentation, you need to understand calibration. Scheduling semiconductor parameter analyzer calibrationsafeguards your measurements and operations. Pay attention to the difference between auto‑calibration and accredited calibration. Recognise the signs of drift in your instruments. Partner with a service provider that offers accreditation, traceability and responsive support.

Providers like Techmaster Electronics show that a calibration service can be more than certificate issuance. It can become a strategic ally. We combine calibration with repair and rental services. This mix minimises downtime. It ensures your critical parameter analyzers, calibrators and other test instruments remain accurate and reliable. In the ever‑evolving world of semiconductor devices, such assurance is invaluable. Ensuring that semiconductor parameter analyzer calibration is performed regularly will keep your measurement systems reliable, compliant and ready to meet the challenges of modern semiconductor testing.