Introduction

In modern laboratories, measurement accuracy is essential. Whether you work in pharmaceutical research, environmental monitoring or industrial quality assurance, the ability to deliver precise volumes of liquid is important for good science. Pipettes – the slender glass or plastic tubes used to transfer measured volumes – play a crucial role in this process. However, even the highest‑quality pipette will drift over time, leading to inaccurate results, compliance problems and waste. Regular pipette calibration ensures that your laboratory instruments deliver the right volume every time, keeps you aligned with global standards and protects your data integrity. This guide offers a clear overview of pipettes, explains why calibration matters and shows how BlauBrand models can act as examples in the discussion. It concludes with a look at Techmaster’s accredited calibration services in the United States, giving you practical next steps for maintaining confidence in your laboratory equipment.

What Are Pipettes and Why Are They Essential in Laboratories?

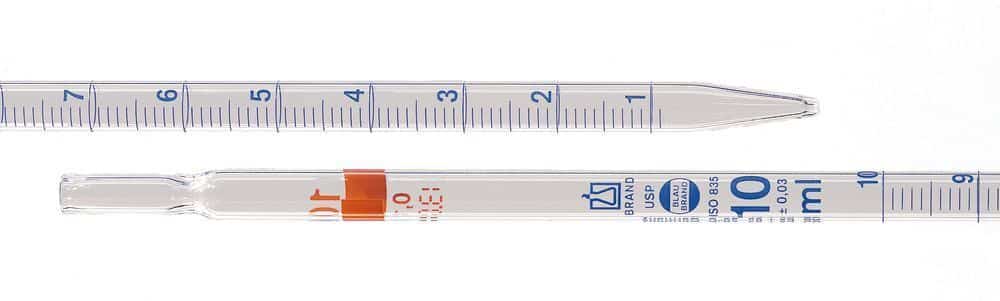

People use pipettes to transfer defined volumes of liquid from one container to another. They range from simple disposable plastic tips attached to mechanical pipettors to high‑quality glassware made to precise tolerances. Broadly, pipettes fall into two families:

-

Volumetric (transfer) pipettes: These deliver one fixed volume extremely accurately. Their narrow waist ensures minimal surface area, reducing the chance of liquid sticking to the glass.

-

Graduated pipettes: Marked with graduations along their length, allowing the user to deliver different volumes by reading the meniscus against a scale. They are versatile but generally slightly less accurate than volumetric pipettes.

Pipettes underpin experiments in chemistry, biology and medicine. In chromatography and titration, small volume errors quickly affect results. Similarly, dosage accuracy affects patient safety in pharmaceutical formulation. For those reasons, most rules and standards, including ISO/IEC 17025 and Good Laboratory Practice (GLP), insist that laboratories maintain calibrated volumetric equipment. Techmaster Electronics notes that it performs calibrations according to recognized global standards and emphasises its accreditation to ISO/IEC 17025 (2017). This ensures traceability to national measurement institutes such as NIST and builds confidence in measurement results.

How Pipette Calibration Works

Calibration involves comparing the volume delivered by a pipette against a known reference under controlled conditions. For glassware such as pipettes, the gravimetric method is commonly used: liquid delivered from the pipette is weighed on a calibrated balance, and the mass is converted to volume using the density of water at a defined temperature. Record environmental conditions (temperature, humidity, and pressure) because they affect density and evaporation. A typical calibration procedure consists of:

-

Pre‑cleaning: Remove contaminants and ensure the pipette is dry.

-

Stabilisation: Allow the pipette and water to reach room temperature to minimise thermal expansion errors.

-

Gravimetric measurement: Deliver multiple aliquots into a weighing vessel and record the mass with a calibrated balance.

-

Data analysis: Convert mass to volume, calculate deviations from nominal value and evaluate measurement uncertainty.

-

Certification: Issue a calibration certificate with results and acceptance criteria.

We visualise these steps in the second chart below. A formal calibration not only adjusts the instrument if necessary but also documents its performance – a crucial requirement for ISO audits and quality control.

Search Intent and User Groups

Different audiences search for “pipette calibration” with distinct goals. Engineers and technicians want high‑precision instruments that meet specific requirements; QA managers and procurement specialists need to maintain compliance and cost‑effectiveness; and students or newcomers seek clear explanations of what pipette calibration entails. This article addresses all three groups by explaining fundamentals and offering technical details without assuming prior expertise.

Graduated Pipettes Explained

Graduated pipettes are slender glass tubes marked with graduations. Unlike volumetric pipettes, which dispense a single fixed volume, graduated pipettes allow users to deliver multiple volumes by reading the liquid’s meniscus against the scale. Two key concepts define their performance:

Class and Tolerance

International standards such as ISO 835 assign tolerance classes (A, AS and B) to pipettes. Class A and Class AS pipettes offer the highest accuracy; Class AS (short for Accuracy Special) is designed for rapid drainage with a waiting time (usually 5 s) to achieve the specified accuracy. Class B pipettes have twice the allowable tolerance and are intended for general laboratory tasks where high precision is not critical. The table below summarises typical differences.

| Parameter | Class AS | Class B |

|---|---|---|

| Tolerance (Accuracy) | ±0.1% (high accuracy) | ±0.2% (lower accuracy) |

| Draining Time | 5 seconds (short) | 10–15 seconds (longer) |

| Typical Uses | Critical research & quantitative analysis | General laboratory tasks & teaching |

| Calibration Frequency | Regular calibration every 12 months | More frequent calibration every 6 months |

In general, laboratories use Class AS pipettes for quantitative analyses such as preparing calibration standards, while Class B suffices for qualitative work or teaching. Regular graduated pipette calibration ensures that real‑world performance matches these nominal classes and compensates for wear or manufacturing imperfections.

TD vs EX (To Deliver vs To Contain)

Manufacturers mark graduated pipettes either TD (to deliver) or EX (ex duis). They calibrate a TD pipette so that when the indicated volume is delivered and the pipette drains, any residual liquid left in the tip is accounted for; the user should not “blow out” remaining drops. For an EX pipette, calibration ensures that the stated volume is contained: you must fully empty it, often using a bulb or blowing mechanism, to transfer the correct volume. Understanding TD/EX distinctions is vital when interpreting pipette markings and ensuring accurate laboratory protocols.

Type 2 and Waiting Time

Type numbers reflect the design of the tip and required waiting time for complete drainage. Commonly found in Class AS versions, Type 2 pipettes require a 5 s waiting period after the meniscus reaches the final graduation mark. This pause allows the liquid column to stabilise, ensuring that the volume delivered corresponds to the calibration.

Materials and Standards in Pipettes

The material of a pipette affects its chemical resistance, thermal stability and durability. AR‑GLAS, a borosilicate glass, offers low thermal expansion and strong resistance to chemicals. Pipettes made from AR‑GLAS maintain their calibration even when exposed to temperature fluctuations and aggressive solvents. Other materials include soda‑lime glass (less chemical resistant) and plastics such as polystyrene or polypropylene used for disposable pipette tips.

Manufacturers design and calibrate pipettes according to national standards. ISO 835 specifies dimensions, tolerances and markings for glass pipettes, while DIN 12690 and related European standards provide additional specifications. German metrological authorities verify pipettes bearing the DE‑M mark, and these pipettes comply with the European Measuring Instruments Directive. When combined with third‑party accreditation such as ISO 17025, these markings give users confidence that the instrument conforms to strict measurement requirements.

Example: BlauBrand’s Graduated Pipettes (Class AS, Type 2, Total Delivery)

To make our discussion concrete, consider BlauBrand’s Graduated pipettes from DWK Life Sciences. DWK Life Sciences manufactures these pipettes from AR‑GLAS, stamps them with the DE‑M seal, and ensures they conform to Class AS, Type 2 specifications. Their design includes high‑contrast graduations, colour‑coded rings for quick volume identification and a constricted tip that drains completely. After the meniscus reaches the final line, wait 5 s for complete drainage. Key characteristics include:

| Feature | Description |

|---|---|

| Material | AR‑GLAS borosilicate for chemical and thermal resistance |

| Class | AS (highest accuracy with waiting time) |

| Type | 2 (with 5 s drain time) |

| Calibration | TD/EX; to deliver specified volume without blowing out |

| Volume range | Typically 1 mL to 50 mL in 0.1 mL increments |

| Certification | Complies with ISO 835, DIN 12690; DE‑M marked |

Common Challenges with Pipettes (and How Calibration Solves Them)

Even high‑quality pipettes exhibit drift over time. Common issues include:

-

Wear of graduation marks: Repeated cleaning or exposure to abrasive media can lighten or blur graduations, making reading difficult and introducing systematic errors.

-

Thermal expansion: Glass expands or contracts with temperature. Unless allowed to stabilise at calibration temperature (usually 20 °C), the volume delivered can differ from nominal values.

-

Residual droplets: Incomplete drainage due to surface tension or contamination leaves micro‑droplets inside the pipette. TD pipettes account for this, but any change in inner surface (e.g., due to scratches) alters the residual volume.

-

User technique: Holding the pipette at an angle, reading the meniscus incorrectly or failing to observe the waiting time can all introduce errors.

Calibration mitigates these problems by revealing drift and enabling corrective action. During calibration, a lab may rinse the pipette with distilled water to ensure consistent wetting; measure multiple deliveries to calculate an average delivered volume; and compare results against tolerance limits. If the pipette fails, technicians can repair it (e.g., by replacing the tip) or replace it. Techmaster Electronics emphasises that its service portfolio includes calibration and repair, giving customers a seamless solution when instruments fail. Because Techmaster holds accreditation to ISO/IEC 17025 and ANSI/NCSL Z540.1, customers receive certificates that organisations around the world recognise. Moreover, Techmaster traces its calibrations to NIST, ensuring that the measurement hierarchy is unbroken.

Calibration Process Visualised

The following chart outlines the key steps in a typical pipette calibration routine. The chart shows why you need a controlled environment and careful documentation.

- Remove contaminants

- Dry pipette thoroughly

- Condition pipette & water

- Reach room temperature

- Deliver multiple aliquots

- Weigh on calibrated balance

- Convert mass to volume

- Calculate average & deviation

- Assess uncertainty

- Verify against tolerance

- Issue certificate & records

By following these steps and working with an accredited laboratory, you reduce sources of error and maintain confidence in your results.

Techmaster’s Calibration Services for Pipettes in the United States

You may now wonder how to implement these best practices in your own laboratory. Techmaster Electronics has more than three decades of experience in calibration and measurement work and offers a complete solution. The company’s range of services—covering calibration, repair and sales/rental—makes it a one‑stop shop for managing test and measurement equipment. According to its materials, Techmaster performs calibrations in line with global standards and maintains traceability to national institutes. It holds accreditation to ISO/IEC 17025 (2017) and meets ANSI/NCSL Z540.1 requirements. The accredited scope spans numerous disciplines – from RF/microwave and electrical to chemical, dimensional and medical equipment such as pipettes. By offering such a diverse range of services, Techmaster simplifies purchasing and scheduling for customers who would otherwise need multiple vendors.

For laboratories in the United States seeking laboratory pipette service, Techmaster can provide on‑site or off‑site calibration with quick turnaround times. Techmaster issues certificates detailing measurement results, uncertainties and conditions. If your pipette fails, Techmaster’s repair service eliminates the need to engage a separate vendor, reducing downtime and administrative overhead. Customers also benefit from sales and rentals of test equipment, ensuring that operations continue while instruments are serviced.

Why Choose an Accredited Laboratory?

An accredited laboratory demonstrates technical competence and management system compliance by undergoing regular audits. Accreditation to ISO/IEC 17025 means the lab’s quality system, measurement procedures and personnel training meet internationally agreed criteria. ANSI/NCSL Z540.1 adds requirements specific to calibration laboratories serving defence and aerospace sectors. Traceability to NIST ensures that your pipette’s calibration can be linked back to a national measurement standard. Maintaining this chain of traceability is essential when results must stand up to regulatory scrutiny.

Conclusion

Pipettes may appear simple, but their impact on experimental accuracy cannot be overstated. Understanding the difference between volumetric and graduated pipettes, recognising how classes and tolerance affect performance and appreciating the importance of TD/EX markings help you select the right tool for your work. Regular pipette calibration reduces drift, ensures compliance with international standards and safeguards the integrity of your results. BlauBrand’s Class AS, Type 2 pipettes illustrate how carefully engineered glassware paired with proper calibration delivers reliable performance. Partnering with an authorised provider such as Techmaster Electronics – whose services are traceable to NIST and accredited to ISO/IEC 17025 and ANSI/NCSL Z540.1 – ensures your instruments remain precise and ready for critical tasks. By investing in regular calibration and choosing high‑quality pipettes, you uphold the standards of excellence that modern science demands.

Ready to schedule your pipette calibration? Contact Techmaster Electronics today.