In electrical and electronic manufacturing, safety is not optional—it’s a core requirement. One inaccurate reading can result in failed audits, rejected shipments, or, worse, unsafe products reaching end-users. That’s why Electrical Safety Analyzer calibration is essential: it ensures test equipment delivers accurate, traceable results, giving engineers, managers, and auditors confidence in product compliance and safety.

What is an Electrical Safety Analyzer?

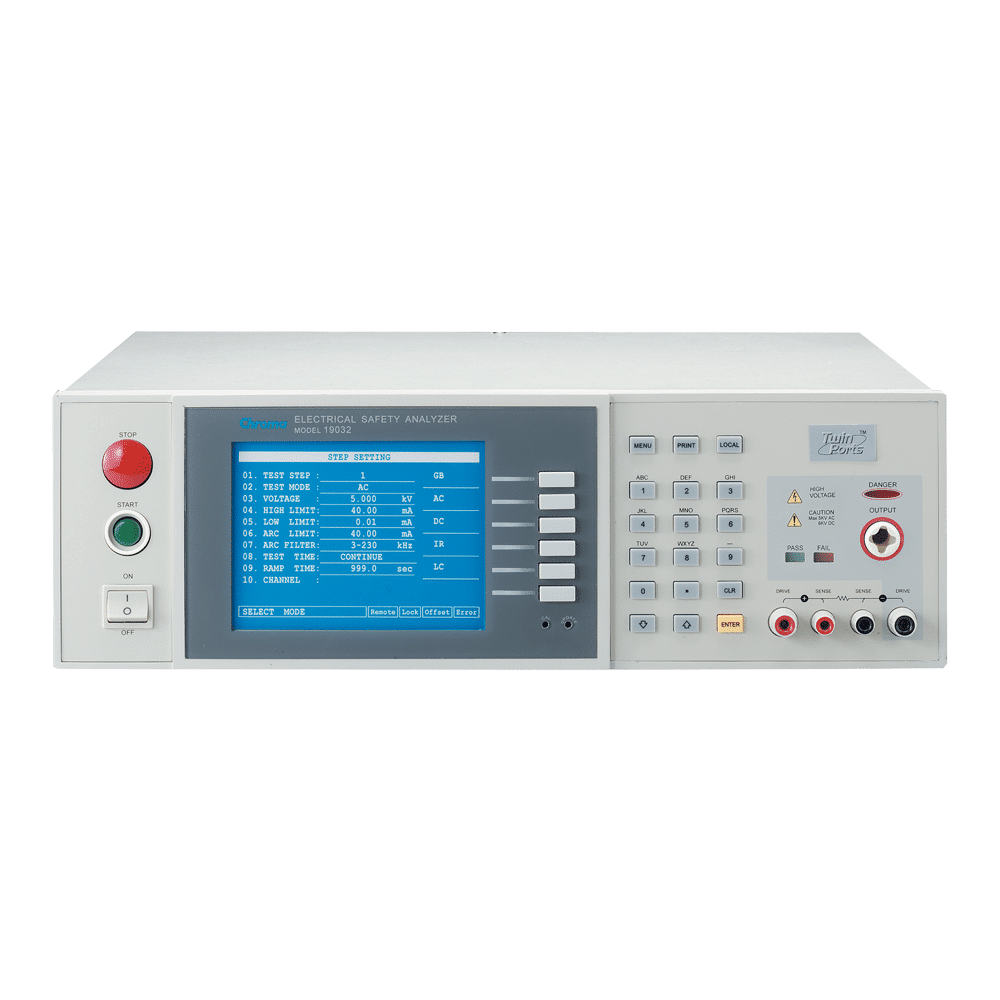

An Electrical Safety Analyzer is a specialized instrument designed to verify the safety of electrical devices. It typically integrates multiple tests, such as:

-

AC/DC Hipot test – verifying insulation withstands high voltage

-

Insulation Resistance (IR) – measuring leakage through insulation

-

Ground Bond (GB) – ensuring protective earth continuity

-

Leakage Current (LC) – checking current leakage to ground

-

Function Test – validating device operation under load

A well-known example is the Chroma 19032, widely used in factories and labs. It combines all five tests in one unit, streamlining safety validation. After calibration, certificates like TDS-7406290 confirm the analyzer’s results are traceable and compliant with ISO/IEC 17025 standards.

The Unseen Guardian of Operator Safety

Why Calibrating Your Electrical Safety Analyzer is Non-Negotiable

An Analyzer is Only as Reliable as its Last Calibration

An uncalibrated Electrical Safety Analyzer (ESA) can provide a false sense of security, passing unsafe medical devices for clinical use. This puts both patients and clinicians at risk from invisible electrical hazards.

The Three Pillars of ESA Calibration

Anatomy of an ESA Test

ESAs perform a suite of tests to measure microscopic currents and verify safety mechanisms. The chart shows typical safety limits for leakage currents (µA). Lower limits indicate more stringent safety—especially for patient-applied parts.

- Protective Earth Resistance: Checks ground integrity.

- Insulation Resistance: Confirms isolation of live parts.

- Leakage Currents: Measures stray currents on chassis or patient leads.

The Meticulous Calibration Lifecycle

Calibration is a precise, multi-stage process performed by trained metrologists to restore an ESA to its exact specifications.

Determining Calibration Frequency

Choosing the Right Calibration Service

When selecting a service provider, consider:

-

ISO/IEC 17025 Accreditation: Techmaster is accredited by ANAB, an ILAC MRA signatory, meaning certificates are globally recognized.

-

Standards Compliance: Techmaster also meets ANSI/NCSL Z540.1 requirements for aerospace and defense clients and ensures NIST traceability for all calibrations.

-

Service Levels: Clients can choose from three tiers—Commercial, ANSI Z540.1, or full ISO/IEC 17025 calibration with uncertainty data.

-

Comprehensive Capabilities: Beyond electrical equipment, Techmaster calibrates RF/microwave, EMC/EMI, dimensional, thermodynamic, mass-mechanical, and even cleanroom and medical instruments.

-

Convenience: With labs in the US, Mexico, Thailand, and Vietnam, plus on-site calibration, quick turnaround, free pickup/delivery, and an online portal for certificate management, Techmaster minimizes downtime.

FAQs

-

Do I need to send my analyzer to the manufacturer? Not necessarily—ISO/IEC 17025-accredited labs like Techmaster can calibrate most major brands.

-

What’s the difference between calibration and adjustment? Calibration verifies and documents accuracy; adjustment corrects deviations.

-

What happens if I skip calibration? Results lose traceability, potentially causing audit failures and product recalls.

-

How much does it cost? Pricing depends on the model and scope—typically ranging from basic traceable calibration to full ISO/IEC 17025 accredited calibration with uncertainty reporting.

ISO/IEC 17025.

This accreditation is your guarantee of technical competence and a valid, traceable calibration.

Calibration is not an expense; it’s an investment in safety and certainty.