AC Current Clamps: Non-Contact Measurement Solutions and the Vital Role of AC Current Clamp Calibration

In the demanding world of industrial and residential electrical engineering, measuring current without breaking the circuit represents a major breakthrough in both safety and efficiency. The AC Current Clamp is the tool that makes this possible. However, a measurement is only as valuable as its precision. To maintain this reliability, the AC Current Clamp Calibration process acts as the essential “key.” This article explores the practical applications of these devices and explains why calibration is a mandatory requirement for every professional technician.

1. How Does an AC Current Clamp Operate?

To understand why calibration is necessary, we must first examine how these devices work. AC current clamps operate primarily on the principle of electromagnetic induction (Faraday’s Law).

Initially, when you clamp the device’s jaws around a conductor carrying an alternating current, the current generates a varying magnetic field. Subsequently, a secondary winding inside the clamp’s jaws induces a small current proportional to this field. Afterward, the device’s internal processor calculates and displays the actual current value on the screen.

Because the jaws must close perfectly to capture the magnetic flux accurately, any mechanical misalignment or component aging will lead to significant errors. Therefore, performing regular AC Current Clamp Calibration is the only way to monitor and correct these variables.

2. Practical Applications in Industry and Maintenance

⚙️

Motor Maintenance

❄️

HVAC Systems

📊

Power Quality

🛡️

Safety & Leakage Current

Thanks to their ability to perform “online” measurements without interrupting the power supply, these devices are found in almost every technician’s toolkit.

2.1. Industrial Motor Monitoring and Maintenance

Inside factories, AC motors serve as the heart of production lines. Technicians use AC current clamps to check both starting and running currents. If the current is unusually high, it indicates an overload or a failing bearing. Detecting these issues early prevents motor burnouts, saving thousands of dollars in repair costs and production downtime.

2.2. HVAC and Refrigeration System Testing

Furthermore, HVAC engineers utilize these tools to diagnose compressors and fans in central air conditioning systems. By measuring the AC current, they can determine if a system is overcharged with refrigerant or if a capacitor is losing its efficiency. Consequently, this leads to better energy management and longer equipment lifespans.

2.3. Building Power Quality Analysis

Moreover, AC current clamps, when combined with harmonic analyzers, help engineers assess power quality. They identify unbalanced currents between phases in 3-phase systems. By doing so, they can redistribute loads to avoid overheating conductors and damaging sensitive electronic equipment.

2.4. Electrical Safety and Leakage Current Testing

During routine maintenance, using high-sensitivity clamps to measure leakage current helps identify faulty insulation points. This protects lives from electric shocks and prevents fires caused by short circuits.

3. Why is AC Current Clamp Calibration So Critical?

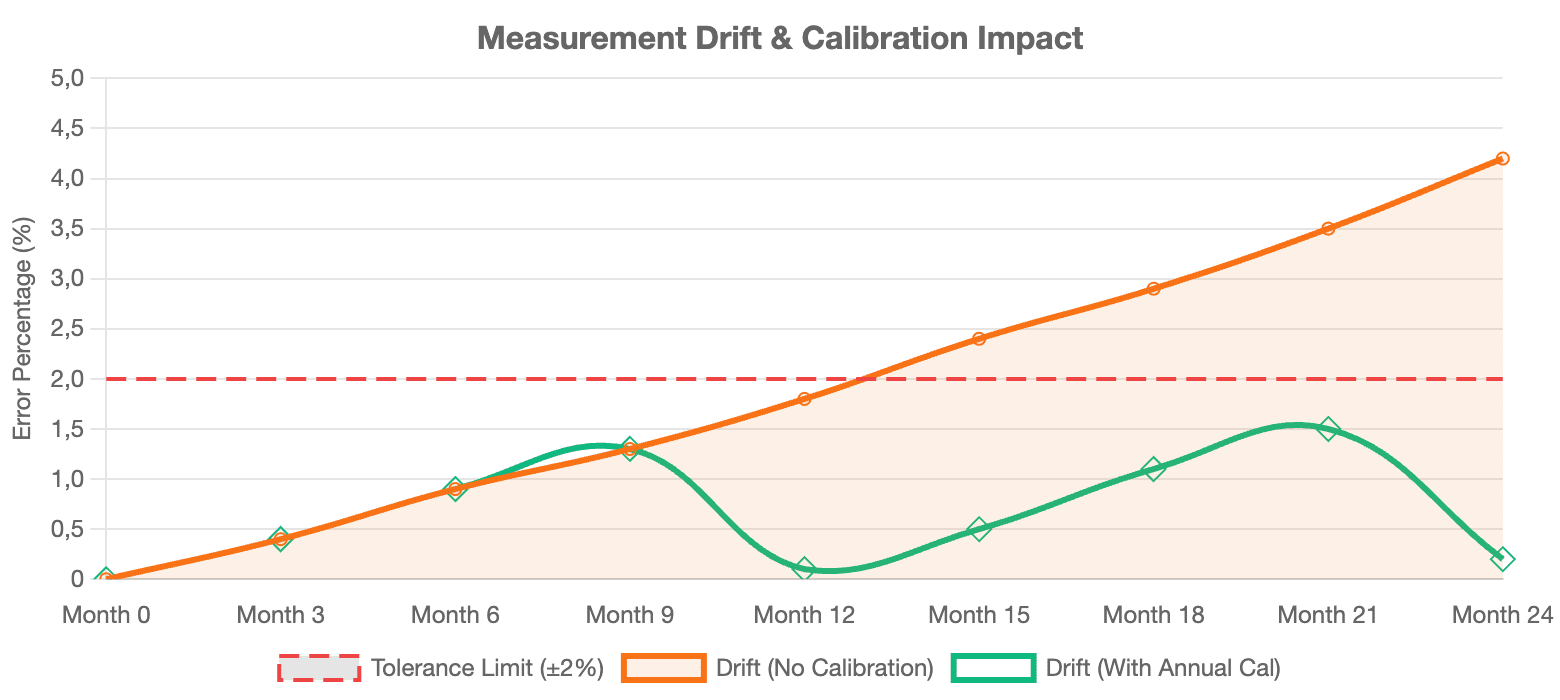

Many users mistakenly believe that current clamps are indestructible and never lose their accuracy. On the contrary, the AC CURRENT CLAMP Calibration process is absolutely essential for several reasons:

🛡️

Personal Safety

📐

Jaw Sensitivity

📜

ISO Compliance

🧲

Magnetic Drift

-

Ensuring Absolute Safety: If a meter displays a reading lower than the actual current (a negative error), a technician might assume a system is safe and proceed with dangerous tasks. This can lead to explosions or fatal electrical accidents.

-

Maintaining Jaw Sensitivity: The device’s jaws open and close thousands of times. Dust, debris, or mechanical wear at the hinges can create a microscopic gap, allowing magnetic flux to escape. Calibration identifies and corrects this loss of sensitivity.

-

International Standards Compliance: Businesses operating under ISO 9001 or ISO 45001 standards must hold valid calibration certificates for all measuring tools to ensure transparency and quality assurance.

-

Compensating for External Magnetic Fields: In industrial environments with high magnetic interference, devices can “drift” from their zero point. Calibration helps the device reset its baseline for the most accurate readings.

4. The Standard Laboratory Calibration Procedure

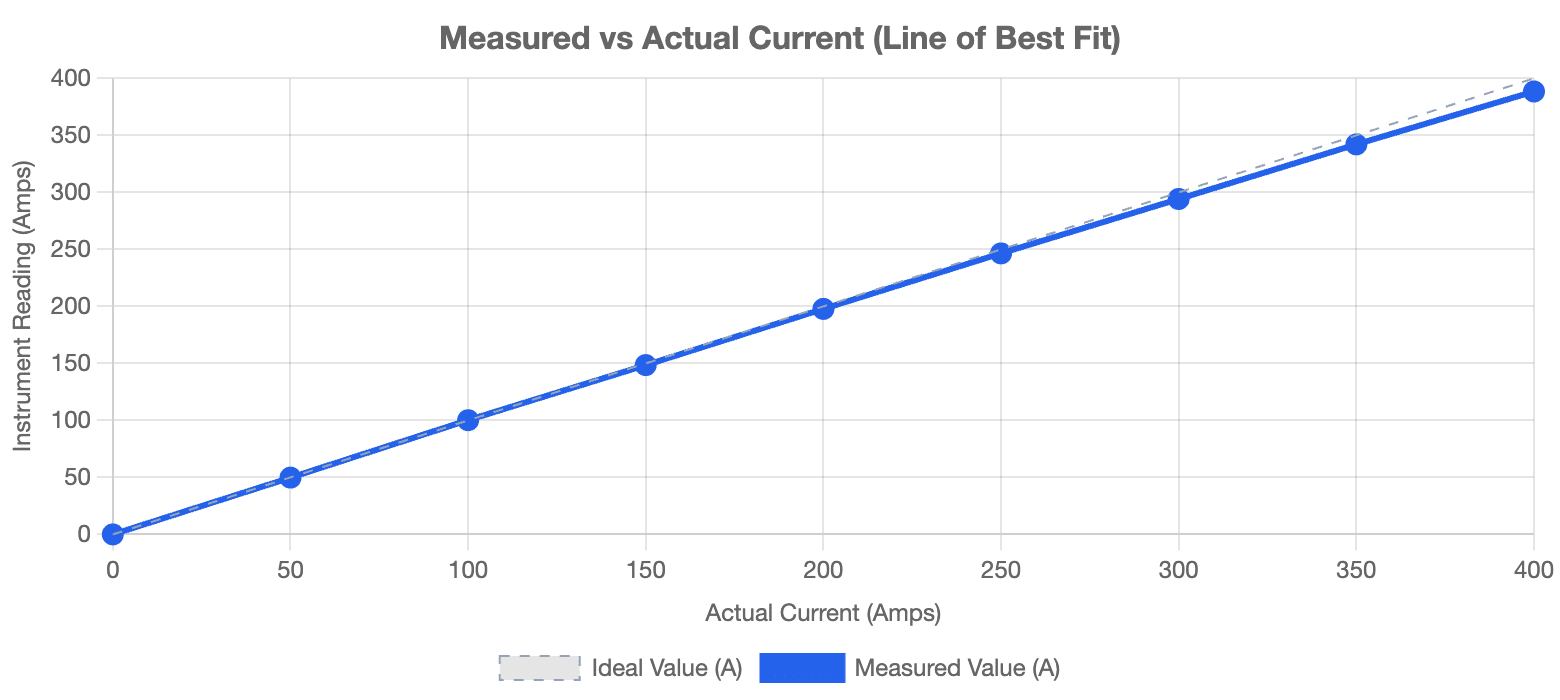

A professional AC Current Clamp Calibration involves a series of rigorous technical steps:

-

Environmental Conditioning: First, the laboratory places the device in a room with stable temperature and humidity for at least two hours to eliminate errors caused by thermal expansion.

-

Mechanical Inspection: The technician checks the tightness of the jaws and the cleanliness of the contact surfaces.

-

Utilizing a Current Calibrator: Next, specialists use a high-precision calibrator capable of producing current at least four times more accurate than the device under test. This source generates AC current levels across various ranges (e.g., 10A, 50A, 100A, 400A).

-

Multi-Point and Multi-Frequency Testing: The technician performs measurements at different current magnitudes and frequencies (typically 50Hz and 60Hz) to ensure the device works accurately across all global power grids.

-

Uncertainty Analysis: Finally, the specialist calculates the measurement uncertainty and issues a formal certificate.

5. Maintenance Tips to Extend Calibration Validity

After completing your AC Current Clamp Calibration , follow these rules to keep the device in top condition:

-

Keep Jaw Surfaces Clean: Even a thin layer of dust or grease on the jaw contact surfaces can cause significant errors. Always wipe them with a soft, dry cloth after use.

-

Avoid Dropping the Tool: The jaws contain brittle ferromagnetic cores. A hard drop can crack the core or misalign the hinge, permanently destroying the device’s accuracy.

-

Store Away from Strong Magnetic Sources: When not in use, keep the device in its specialized case and away from large transformers or permanent magnets.

Conclusion

In summary, the AC current clamp is an indispensable tool for ensuring that electrical systems run smoothly and safely. However, do not let inaccurate readings mislead you. Performing regular AC Current Clamp Calibration is not just about following regulations; it is a proactive measure to protect your assets and your life. Invest in calibration to turn your clamp meter into the most reliable and precise “referee” in every measurement.

6–12 Mo

Before significant drift

~2.5%

Per year without service

Annual

Recommended by ISO

99.8%

After professional calibration