High‑power DC electronic loads let engineers test batteries, solar panels and converters by drawing controlled current from DC sources. High Power DC Electronic Load Calibration keeps these programmable instruments accurate and prevents the drift that occurs over time. This guide summarises how the devices work, why calibration matters and how to choose a service provider. It aims to help engineers, managers and curious readers trust their equipment and know when to call professionals.

Understanding High‑Power DC Electronic Loads

What These Instruments Do

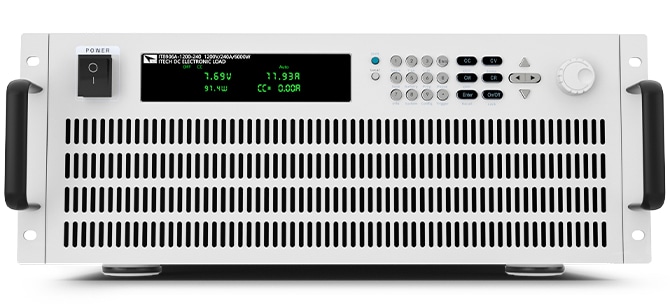

A high‑power DC electronic load is a programmable instrument that simulates electrical loads on DC sources. By switching between constant current, constant voltage, constant power and constant resistance modes, it allows engineers to check how power supplies, battery packs and converters behave. Unlike simple resistive load banks, these loads reproduce dynamic conditions through fast transients and pulsed waveforms. Safety features, data logging and user‑defined waveforms make them versatile tools in laboratories and production lines.

Common Uses Across Industries

High‑power DC loads support many types of testing. They evaluate power supplies and converters, discharge batteries for capacity and safety checks, and validate electric‑vehicle, aerospace and defence power systems. They also test renewable‑energy, industrial and telecom equipment for efficiency and reliability. Each of these applications benefits from accurate calibration because miscalibrated loads can introduce false readings that lead to poor designs or unsafe products.

Why Calibration Matters for High‑Power DC Electronic Loads

Keep Measurements Accurate and Safe

All electronic instruments drift over time. Mechanical wear and environmental changes shift component values so that readings no longer match specifications. Experts emphasise that all mechanical parts wear and all electronic components drift, meaning an uncalibrated instrument cannot be trusted indefinitely. Regular calibration aligns the device with a known reference. It ensures the load measures current, voltage and power within specified tolerances, which is critical for safe testing of high‑energy systems like EV batteries or medical devices.

Detect Drift and Restore Performance

Calibration involves comparing an instrument’s output to a reference standard with traceable accuracy. Any deviation is corrected to return the device to its precise state. Since component aging and temperature changes can introduce errors, this process finds and fixes drift before it leads to errors. Using accurate loads helps engineers spot real issues in their designs rather than chasing artefacts caused by faulty instrumentation.

Improve Product Quality and Reliability

Accurate test equipment prevents defective products from reaching customers. Calibration ensures that measured values reflect reality. By catching problems early in the production process, it reduces rework, warranty claims and reputational damage. Manufacturers of power supplies, battery packs and renewable‑energy systems depend on calibrated loads to validate that their products perform as designed.

Save Money Through Efficiency

Investing in calibration may look like an extra cost, but it delivers savings. Apex Waves notes that calibrated instruments avoid expensive errors and minimise repair or replacement costs. Accurate measurements reduce the number of repeat tests, shorten development cycles and extend equipment life. Managers appreciate that calibration can pay for itself through higher productivity and fewer failures.

Meet Compliance and Traceability Requirements

Many industries require traceable and certified test equipment. Calibration provides a direct link to national or international standards, which is essential for audits. The most common requirement is annual calibration, though intervals may change depending on the criticality of the application. Critical systems might need quarterly or semi‑annual calibrations, while less critical equipment can operate on a longer schedule. Tracking calibration trends helps decide how often to calibrate each device.

Ready to maintain accuracy and compliance? Contact Techmaster Electronics for professional High Power DC Electronic Load Calibration and keep your critical tests on track.

The Calibration Process for High‑Power Loads

Calibrating a high‑power DC load requires careful work. Here is a simplified overview:

-

Preparation: Allow the load to warm up and stabilise under controlled temperature and humidity. Stable conditions reduce measurement variability.

-

Reference standards: Use reference instruments—precision shunts, voltage standards and high‑accuracy meters—that exceed the accuracy of the device under test. The calibration lab maintains these standards with traceability.

-

Baseline measurement: Set the electronic load to specific values of current, voltage and power. Compare the device’s readings to the references and record deviations.

-

Adjustment: If readings fall outside acceptable tolerances, technicians adjust calibration constants to bring the load back within spec.

-

Verification: After adjustments, verify accuracy across the device’s range and test dynamic behaviours such as transient response, constant‑power mode and pulsed loading.

-

Documentation: Issue a certificate detailing measurement results, uncertainties and traceability. This documentation supports quality systems and audits.

Professional calibration services follow these steps using specialised tools and trained technicians. They also handle kilowatt‑level power safely and provide formal certificates (ISO/IEC 17025, NIST traceable) that satisfy regulatory requirements.

Preparation

Warm up the load and stabilise it in a controlled environment to minimise measurement drift.

Reference

Use high‑precision shunts, voltage references and meters with traceable accuracy as the benchmark.

Baseline

Apply known current, voltage and power values to the load and record deviations from the reference.

Adjustment

Correct readings by tuning internal settings until measurements fall within allowed tolerances.

Verification

Re‑measure across the full range and check dynamic modes (transient, constant‑power, pulsed) to ensure accuracy.

Documentation

Provide a certificate summarising results, uncertainties and traceability to support audits and quality systems.

Note: Specialised calibration services perform these steps using trained technicians and handle high‑power equipment safely, supplying ISO/IEC 17025 and NIST‑traceable certificates.

Choosing a Professional High Power DC Electronic Load Calibration Provider

Selecting the right calibration partner is essential. Here are key factors to consider:

Accreditation and Standards

-

ISO/IEC 17025 accreditation: This international standard proves that a lab’s measurements are accurate and traceable. Providers accredited to ISO/IEC 17025 demonstrate technical competence and robust quality systems.

-

ANSI/NCSL Z540.1 compliance: This US standard is important for aerospace and defence clients. It ensures the lab’s procedures meet industry requirements.

-

Traceability: Look for labs that maintain traceability to national institutes such as NIST. Traceability allows measurements to be compared across organisations and countries.

Experience and Technical Capability

-

Broad voltage and current range: High‑power loads vary from tens of volts to hundreds of volts and from tens to hundreds of amps. Choose a provider that can calibrate across the entire range of your equipment.

-

Mode support: Ensure the lab can calibrate all operating modes—constant current, constant voltage, constant power and constant resistance—as well as dynamic features like transient or pulsed loading.

-

Equipment and expertise: A qualified provider uses high‑accuracy calibrators, precision shunts and power analysers. They should also understand related instruments like multimeters and oscilloscopes to support complete test setups.

Service Flexibility and Logistics

-

On‑site vs. laboratory calibration: On‑site service minimises downtime for heavy or critical equipment. Laboratory calibration may offer lower cost or faster turnaround. A good provider offers both options.

-

Turnaround time and logistics: Ask about standard and expedited services, free pick‑up and delivery, and rental options if your equipment must stay in service during calibration.

-

Digital tools: Online portals for downloading certificates and viewing calibration histories streamline record‑keeping. Automatic reminders help you schedule calibrations before expiry.

Customer Support

-

Responsive communication: Direct access to technical experts by phone or email is vital when you have questions or need support.

-

Repair and rental services: Providers that also repair or rent test equipment can reduce downtime and simplify vendor management.

Using these criteria will help you evaluate providers quickly and find one that meets your technical and logistical needs.

Techmaster’s Approach to High‑Power DC Load Calibration

Techmaster Electronics is a long‑standing calibration partner with over 30 years of metrology experience. The company combines calibration, repair and rental services, allowing customers to manage the full lifecycle of their test equipment in one place. Here’s what sets Techmaster apart:

-

Accredited and compliant: Techmaster’s labs are accredited to ISO/IEC 17025 and comply with ANSI/NCSL Z540.1. All calibrations maintain traceability to NIST or other national metrological institutes, giving customers confidence in the results.

-

Broad capabilities: Techmaster calibrates high‑power DC loads and many other instruments—RF/microwave gear, electrical calibrators, EMC/EMI equipment, vibration sensors, frequency counters, medical devices, thermal sensors and mechanical tools. This wide scope means you can send multiple types of equipment to one provider.

-

Flexible service delivery: With labs in Vista, CA, Fremont, CA, Orlando, FL, San Antonio, TX and international sites in Mexico, Thailand and Vietnam, Techmaster provides both local and global coverage. On‑site calibration is available for large or sensitive equipment, while laboratory service offers quick turnaround and precision. Free pick‑up and delivery, plus expedited options, help minimise downtime.

-

Customer support and digital tools: Techmaster offers a web‑based portal where clients can download certificates, view equipment history and receive recall notices. Dedicated phone numbers and email addresses provide direct access to experts. Repair and rental services support continuity when equipment is out for calibration.

By combining accreditation, experience, flexibility and strong customer support, Techmaster offers a comprehensive solution for Calibrating High Power DC Electronic Loads. Whether you need on‑site service, quick lab calibration or help managing multiple instruments, Techmaster’s integrated approach helps you maintain compliance and reliability without unnecessary downtime.

Conclusion

High‑power DC electronic loads enable engineers to design and verify new power electronics, batteries and renewable‑energy systems. High Power DC Electronic Load Calibration keeps these instruments accurate, safe and compliant. Routine calibration corrects drift, ensures traceability and supports product quality. Managers can save time and money by scheduling calibration at appropriate intervals—often annually, but sometimes more often for critical applications. When you select a calibration provider, look for accreditation, technical range, flexible service and responsive support. Techmaster Electronics delivers all of these while helping you manage your entire instrument portfolio.

Protect your investment and ensure reliable measurements. Contact Techmaster today to discuss a calibration program tailored to your high‑power DC electronic loads and other test equipment.