The Holiday Detector: Infrastructure’s Shield and The Absolute Necessity of Calibration

In the oil and gas, chemical, and infrastructure construction industries, the corrosion protection coating is the first and most critical line of defense safeguarding metal from environmental destruction. Any minor flaw in the coating—known as “pinholes,” “holidays,” or thin spots—is a potential initiation point for corrosion. Corrosion can lead to pipeline leaks, tank failures, and cause serious environmental disasters and significant financial losses. The High-Voltage Holiday Detector is an indispensable tool. It works by scanning high voltage across the dry coating, detecting any invisible defects. This device ensures the integrity of the protective layer. However, its detection efficacy entirely relies on the accuracy of its voltage output. Therefore, routine Holiday Detector Calibration is a mandatory requirement to verify that the applied voltage is accurate and compliant with coating standards (e.g., 12,500 Volts for a 25 mil coating), ensuring no dangerous flaw is missed.

1. What is a Holiday Detector? The Core Operating Principle

A Holiday Detector is a Non-Destructive Testing (NDT) instrument used to verify the continuity of an insulating coating applied over a metallic substrate.

1.1. Objective and Technology

- Objective: To detect minute flaws such as pinholes, cracks, or areas where the coating is thin (ranging from 6 mil to over 250 mil).

- Operating Principle (High Voltage):

- The device applies a continuous high voltage (typically from 500V to 35,000V to a brush electrode or a wet sponge.

- When the brush passes over a perfect coating, nothing happens.

- When the brush passes over a flaw (a holiday) to the metallic substrate, the voltage discharges through the flaw.

- This discharge completes an electrical circuit, triggering an audible and visual alarm on the device.

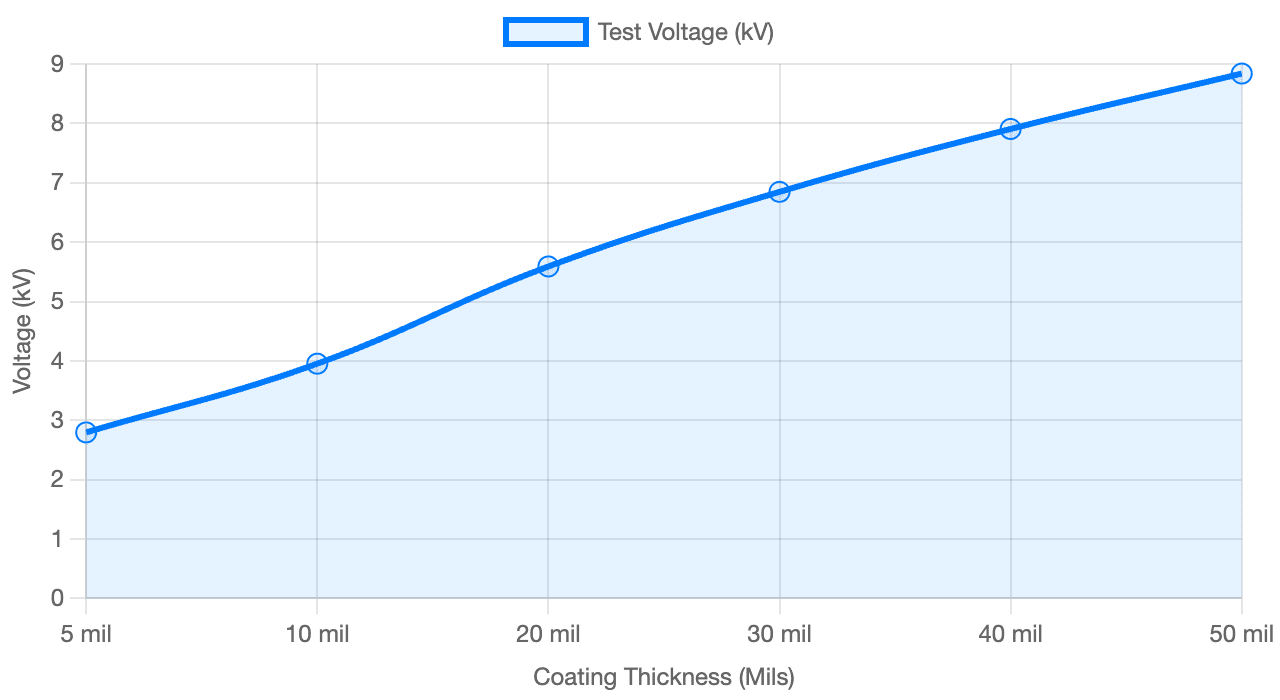

1.2. Standard Voltage Formula

The voltage required for coating inspection is proportional to the coating thickness. Industry standards (such as NACE, ASTM) provide calculation formulas to establish the precise voltage:

Core Principle

Holiday Detectors ensure protective coatings remain intact. Correct voltage is calculated using the universal NDT formula below.

Voltage Formula

- V: Test Voltage (Volts)

- T: Coating Thickness (mils)

- M: Constant (1250 or 1500)

Example: 25 mil → 1250 × √25 = 6250 V

Detection Process

✔ Perfect Coating

High voltage passes → no current path → no alarm

⚠ Holiday Detected

Fault allows spark → discharge → alarm triggered

2. Vital Applications in Industrial Infrastructure

Ensuring coating integrity prevents corrosion-related structural failure across multiple sectors.

Oil & Gas Pipelines

Testing external and internal polymer coatings.

Marine & Construction

Ships, offshore structures, steel bridges.

Chemical & Water Treatment

Epoxy & rubber-lined chemical tanks.

The ability to verify coating integrity is a key factor in extending asset lifespan and ensuring operational safety.

2.1. Oil & Gas and Pipelines

- Transmission Pipelines: The most critical application is inspecting external coatings on oil, gas, and water pipelines. Imperfect coatings on buried pipelines are the primary cause of galvanic corrosion.

- Storage Tanks and Pressure Vessels: Inspecting the internal linings of tanks holding chemicals, fuels, and clean water. A single flaw can lead to a hazardous chemical leak.

2.2. Construction and Marine Infrastructure

- Steel Structures: Inspecting the anticorrosion coating of bridges, steel beams, and offshore platforms.

- Ship Hulls and Ports: Checking the anti-fouling and anti-corrosion paint on ship hulls, dock piling, and structures exposed directly to seawater.

2.3. Water Treatment and Chemical Plants

- Chemical Storage Tanks: Inspecting specialized linings (like Epoxy or rubber) inside tanks holding highly corrosive chemicals (acids, bases), ensuring no flaw allows contact with the metal substrate.

3. The Absolute Role of Holiday Detector Calibration

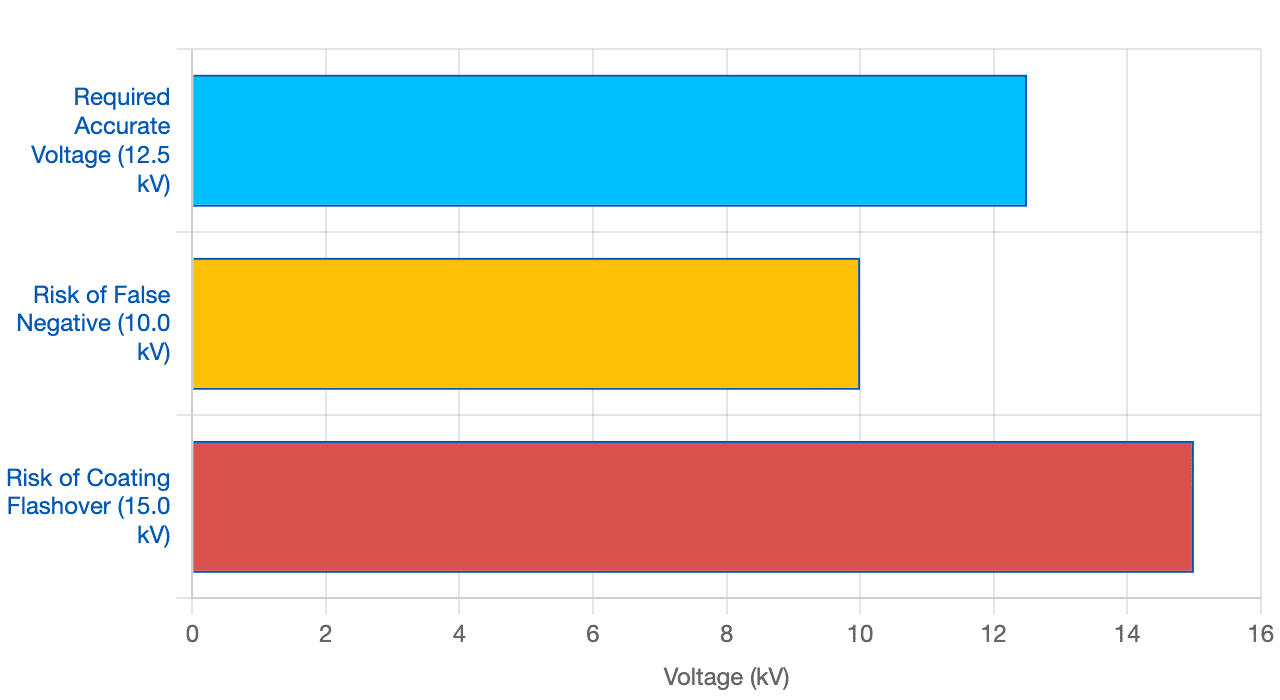

Risks of Incorrect Voltage

Voltage Drift Consequences

Voltage deviation, even minor, violates standards and can lead to critical inspection failure.

Required Voltage vs Thickness

The required voltage increases with the square root of the coating thickness.

Any deviation in the output voltage can lead to catastrophic consequences, making the Calibration process paramount.

3.1. Ensuring Voltage Accuracy and Standard Compliance

- The Risk of Undertesting: If the actual output voltage is lower than the displayed value, the device might not have enough energy to discharge through a small flaw. Consequently, a real defect is missed (False Negative), and an imperfect coating is approved.

- The Risk of Overtesting: If the actual output voltage is higher than the displayed value, the device might cause a flashover even in areas of perfect but thin coating. This damages the coating, creates new defects, and necessitates unnecessary repairs.

- Value Verification: Calibration verifies that the device is generating the precise voltage (Volts) corresponding to the coating thickness (Mils) as dictated by the standard formula (V = M × √T)

3.2. Legal Compliance and Safety Regulations

- NACE/ASTM Requirements: Industry standards such as NACE SP0188 and ASTM G62, D5162 mandate that holiday detectors must be calibrated by an ISO/IEC 17025 accredited laboratory on a periodic basis (typically annually).

- Traceable Evidence: The Calibration Certificate is the only documentation that proves the coating inspection procedure was valid, which is essential for warranty claims, insurance contracts, and quality audits.

4. How Calibration Works

The process of High-Voltage Holiday Detector Calibration requires specialized measuring instruments:

- Reference Equipment: Using a highly accurate, traceable Calibrated High-Voltage Meter as the primary standard.

- Point Checks: A technician checks the holiday detector’s output voltage at multiple set points (e.g., 5 kV, 10 kV, 15 kV…)

- Adjustment: If the actual measured voltage exceeds the allowable error limits, the device is adjusted (trimmed) to ensure accuracy.

- Certification: A detailed certificate is issued confirming the accuracy of the voltage output and the next due date for calibration.

Calibration Process

Conclusion

The Holiday Detector is a critical tool safeguarding billions of dollars in industrial infrastructure. It forms the essential link between coating application and quality assurance, ensuring every protective layer performs as intended. Its reliability, however, depends entirely on one key factor: accurate test voltage. Even minor voltage drift can lead to missed defects or unnecessary coating damage.

Because of this, routine calibration is not optional. It is a mandatory, standards-driven process that ensures precise readings, prevents hidden coating failures, and maintains long-term asset integrity and operational safety across industries.

YOUR RELIABLE CALIBRATION PARTNER

Don’t let equipment inaccuracies jeopardize your research and production.

TECHMASTER ELECTRONICS

ISO/IEC 17025 accredited calibration service provider, ensuring traceability to national measurement standards.