At Techmaster, we continue to expand our technical scope to better serve our clients.

Our newly accredited environmental testing capabilities ensure cleanrooms and controlled areas meet strict ISO 14644 and ISO/IEC 17025 standards.

These services help industries like pharmaceuticals, electronics, and medical manufacturing maintain product safety and quality under precise environmental conditions.

Why Controlled Environments Matter

In highly regulated industries, cleanliness and precision are non-negotiable.

Controlled areas ensure that every process occurs under specific environmental conditions.

In addition, these environments help protect products from contaminants such as dust, microorganisms, aerosols, and chemical vapors — all of which can seriously compromise safety and quality.

Moreover, cleanrooms must regulate key parameters like temperature, humidity, and pressure.

By maintaining these factors within tight limits, companies reduce risk and ensure consistency across production cycles.

What Is a Cleanroom?

Technically, a cleanroom is a space where incoming air is filtered and continuously recirculated through HEPA or ULPA filters.

This process removes contaminants and keeps particle concentration within defined limits.

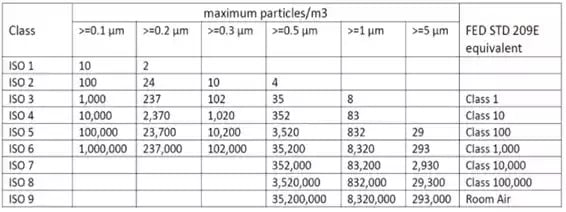

Cleanrooms are classified by the number and size of particles per cubic meter of air.

According to ISO 14644-1, there are nine classes, ranging from ISO Class 1 (the cleanest) to ISO Class 9 (equivalent to normal room air).

Our Accreditation and Standards

Our environmental testing services operate under the accreditation scope of ISO/IEC 17025:2017 and ANSI/NCSL Z540-1-1994 (R2002).

These standards guarantee technical competence, reliability, and traceability.

Additionally, our tests comply with ISO 14644:2015, ensuring that your cleanroom meets global performance and cleanliness criteria.

Our Cleanroom Testing Services

We now provide a full range of environmental and cleanroom validation tests, including:

-

Particle count test

-

HEPA airflow measurement

-

HEPA system leakage test

-

Environmental condition test

-

Recovery test

-

Containment test

-

Airflow visualization test

We also offer testing for critical containment and air-control devices, such as:

-

Flow hood device test

-

Biological safety cabinet test

-

Laminar airflow workstation test

-

Compressed air purity test

These services help you verify that your equipment and controlled environments function safely and efficiently.

Our Competitive Advantages

With over 30 years of experience in calibration and testing, Techmaster truly understands your operational needs.

Over the years, we have combined technical expertise with responsive customer service to deliver reliable and timely results.

Because of this, our clients trust us to support their most critical processes.

By choosing Techmaster, you will:

-

First, receive local service that helps you lower overall costs.

-

Next, enjoy friendly, high-quality, and personalized customer support.

-

Then, schedule testing at the time that best fits your production plan.

-

Finally, work with expert technicians who use carefully calibrated validation equipment.

Commitment to Quality and Innovation

At Techmaster, every new capability reflects our ongoing mission: to deliver precision, compliance, and confidence in every measurement.

Our environmental testing services reinforce that commitment — ensuring your controlled areas perform safely and consistently, every time.

Click here to view the full Environmental Testing Brochure.