Pressure Gauges: The “Eyes” of a Fire System and the Crucial Role of Calibration

Every component in a fire protection system matters. Each part helps safeguard lives and property. Among these, the pressure gauge acts as the “eyes” of the entire system. It is not just a measuring tool, it is a vital indicator. It tells us if a fire suppression system is ready to fight a fire. An inaccurate pressure gauge can create a false sense of security. This leads to devastating consequences when a fire breaks out. This article will explain the essential role of pressure gauges in fire suppression systems. It will also analyze the importance of pressure gauge calibration.

1. What is a Pressure Gauge?

A pressure gauge is a device that measures and displays pressure. It works with liquids, gases, or vapor in a closed system. The device works mechanically or electronically. It converts pressure into a physical movement. This moves a pointer or sends an electronic signal. The most common design uses a Bourdon tube. This is a hollow metal tube. It straightens as pressure increases. This action moves the pointer.

Industries widely use this device. People use it to monitor tire pressure. Manufacturers use it to control compressed air systems. The oil and gas industry uses it for complex applications. However, its function goes far beyond simple measurement in a fire suppression system.

2. The Vital Role of Pressure Gauges in Fire Suppression Systems

In a fire suppression system, pressure determines its effectiveness. Insufficient pressure means water or other agents cannot be discharged with enough force. This fails to control a fire. Conversely, too much pressure can burst pipes. It can also damage other equipment. The pressure gauge helps us continuously monitor and control this critical factor.

- Monitoring Readiness Status: This is the most crucial role. Pressure gauges on portable fire extinguishers help staff check the system’s status. The gauge’s needle sits in a safe pressure zone (usually the green line). This shows the system is ready. If the needle is in the red zone, the pressure is too low or too high. Users must take immediate action.

- Ensuring Optimal Discharge Performance: In sprinkler or foam systems, a specific pressure level must be maintained. The pressure gauge helps control this pressure. This ensures that water or foam discharges with enough force. It covers the fire area effectively.

- Preventing Malfunctions: The pressure gauge also acts as an early warning tool. An abnormal pressure drop may signal a leak. A sudden pressure increase could indicate a blockage. Early detection helps prevent major damage. It ensures the system remains functional.

3. Calibration: The Gold Standard for Reliability and Safety

Pressure gauges are essential. But their value depends on their accuracy. An inaccurate gauge gives false information. This leads to an incorrect assessment of the system’s status. This is why calibrating pressure gauges in fire suppression systems is a critical and mandatory task.

Calibration is a process. It tests and adjusts a measuring device. It ensures the device displays accurate results against a recognized standard. In fire protection, this provides several benefits:

- Ensuring Absolute Accuracy: Calibration helps detect and eliminate gauge errors. It ensures the displayed pressure information is always correct. A gauge that shows sufficient pressure when it is actually lacking has tragic consequences. This happens because the user trusts the misleading information.

- Compliance with Legal Standards: Fire protection regulations require periodic calibration of measuring devices. This ensures a system’s full compliance with safety codes. Non-compliance poses a significant risk. It can also lead to legal penalties.

- Extending Equipment Lifespan: The calibration process includes a full inspection. This helps us find hidden damage early. We can then perform timely maintenance and repairs. This extends the lifespan of both the gauge and the entire system.

4. The State of Pressure Gauge Calibration in the U.S.

The State of US Calibration

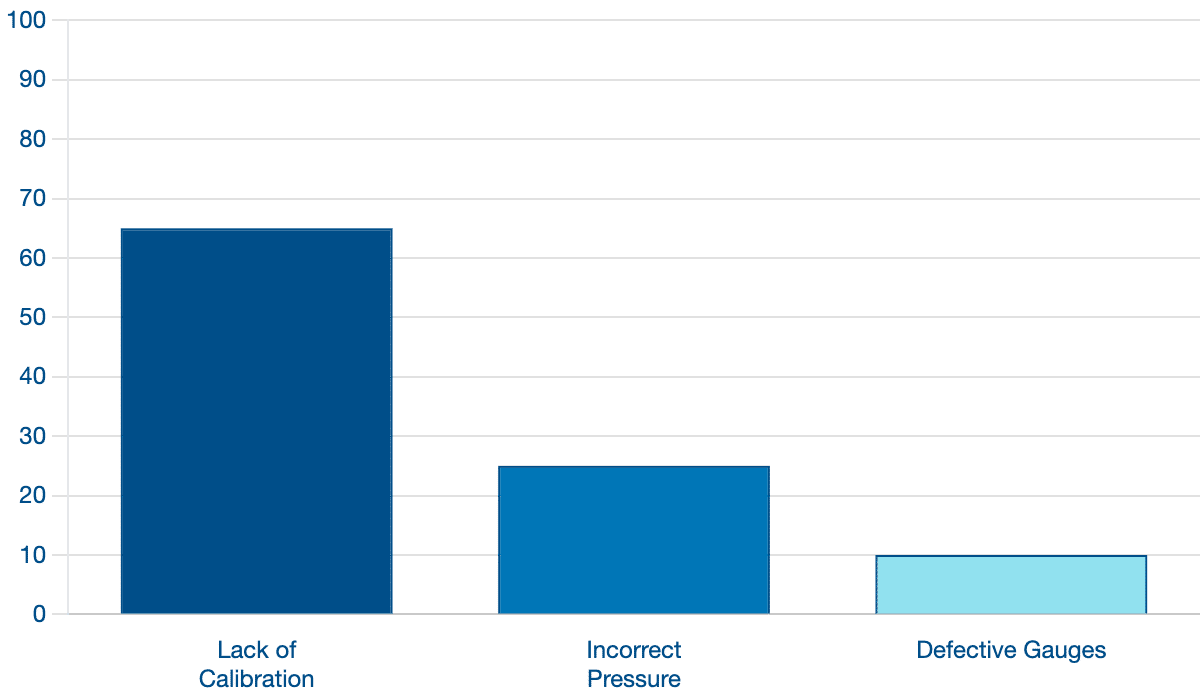

Fire protection systems are the first line of defense for people and property. One of their most critical, yet often overlooked, components is the pressure gauge. Its accuracy determines the effectiveness of the entire system. However, the reality shows significant challenges.

In the U.S., fire safety is a priority. Organizations like the National Fire Protection Association (NFPA) and the Occupational Safety and Health Administration (OSHA) manage it. The awareness of pressure gauge calibration is highly standardized.

- NFPA 25 Standard: This is the core standard for inspections. It covers testing and maintenance of water-based systems. NFPA 25 requires us to replace or calibrate pressure gauges every 5 years. The standard specifies a calibration accuracy of no more than 1% of the full scale.

- Rigorous Inspection Process: Local fire marshals perform regular inspections. They require inspection reports and calibration certificates. Not complying with these requirements can result in fines. It can also lead to suspension of operations. In some cases, it can lead to severe penalties if an incident occurs.

- High Safety Awareness: U.S. building owners and businesses have high legal responsibility for fire safety. They invest in maintenance and calibration. It is a business strategy. They do it to mitigate risk. It protects assets and avoids costly lawsuits.

Objective Evaluation Criteria

Choosing a calibration company should be based on more than just price. Here are the top objective criteria used to evaluate a service provider, ensuring quality and reliability.

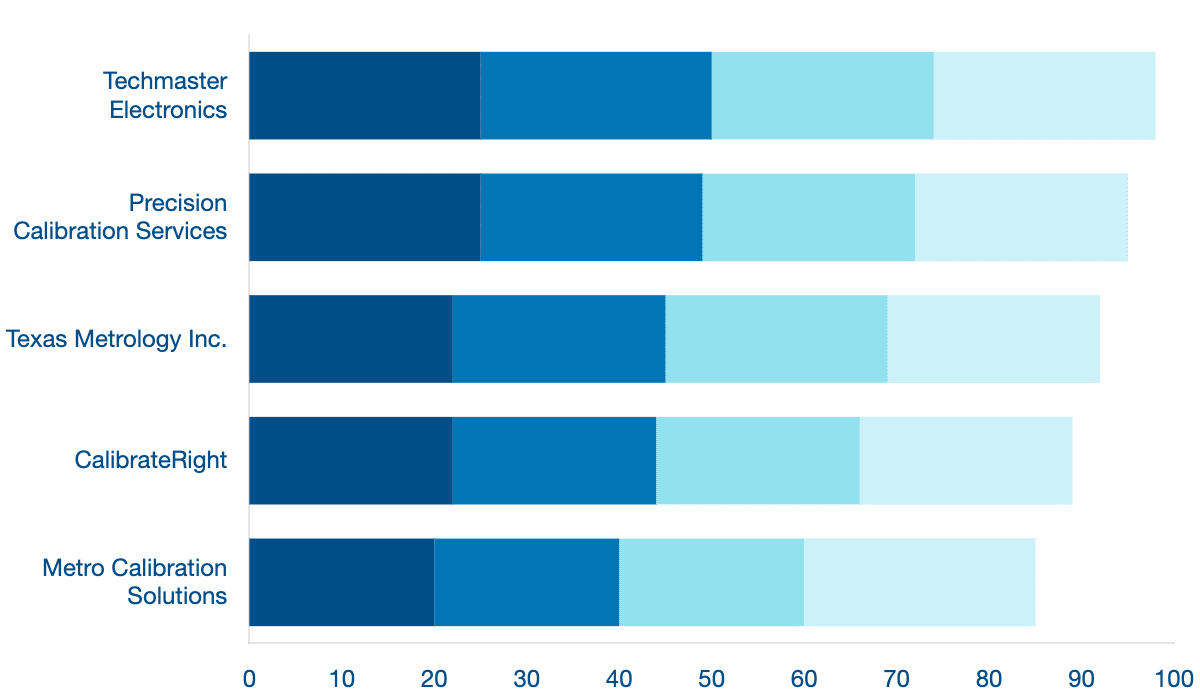

Top 5 Best Calibration Service Companies in Texas

Based on the above criteria, here are the top-rated companies for their expertise, reliability, and service responsiveness in Texas.

Conclusion

A pressure gauge is a crucial component in an effective fire suppression system. Its role extends beyond just showing pressure. It ensures the safety and performance of the entire system. However, a gauge is only valuable when it is accurate. Therefore, we must perform periodic calibration. It is a mandatory investment. It ensures your fire protection system is always ready to protect lives and property. This provides absolute peace of mind. Raising awareness and adhering to calibration regulations is a legal and social responsibility for every business and individual.