Thermocouple Simulator Calibration: An Essential Pillar of Complex Industrial Fire Safety

In today’s industrial world, factories run complex processes. They often involve high temperatures and many fire and explosion risks. Fire protection (FP) is more than just a rule; it’s vital for human and asset safety. To make any FP system effective, every part of the monitoring and control chain must work perfectly. Thermocouple simulator calibration is a crucial, often overlooked, part of this process. It forms a silent, yet critical, foundation for fire protection, especially in complex industrial environments.

Understanding Thermocouples and Thermocouple Simulators

To truly understand calibration’s importance, we first need to know about thermocouples and thermocouple simulators.

What is a Thermocouple?

A thermocouple is a common temperature sensor. It works on the Seebeck effect. When two different metals join and a temperature difference exists between them, a small voltage (mV) develops. This voltage relates directly to the temperature difference. Therefore, it allows for temperature measurements across a wide range, from low to very high temperatures (up to 2300°C for some special types). Industries like chemical, oil and gas, metallurgy, power generation, and food processing widely use them. They monitor temperatures in furnaces, pipelines, boilers, and other crucial industrial processes.

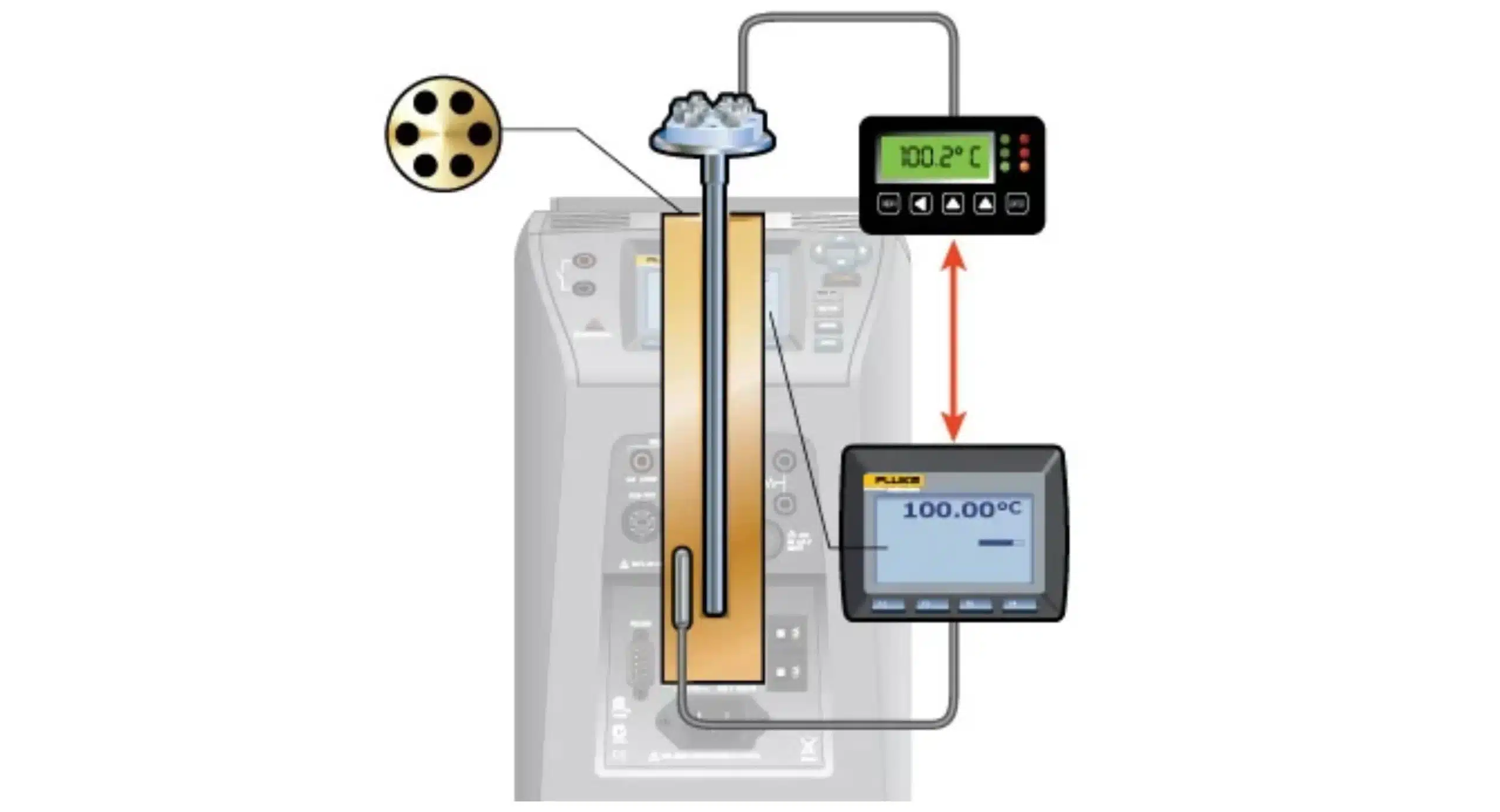

What is a Thermocouple Simulator?

A thermocouple simulator is a specialized electronic device. It generates a voltage signal (mV) identical to what a real thermocouple produces at a specific temperature. Technicians can “simulate” various temperature conditions safely and accurately with it. This happens either on-site or in a laboratory. It eliminates the need to expose a thermocouple to an actual temperature environment for testing. Simulators are essential tools. They help test, diagnose, and calibrate input devices that receive signals from thermocouples. These include:

- Temperature controllers

- Dataloggers

- Temperature indicators

- Analog input modules of industrial control systems (PLCs, DCS)

The Critical Importance of Accurate Temperature in Industrial Fire Protection

In factories, temperature is more than just a process parameter. It’s also a key indicator of safety. Small measurement inaccuracies can lead to disastrous outcomes. This holds especially true for fire protection and prevention.

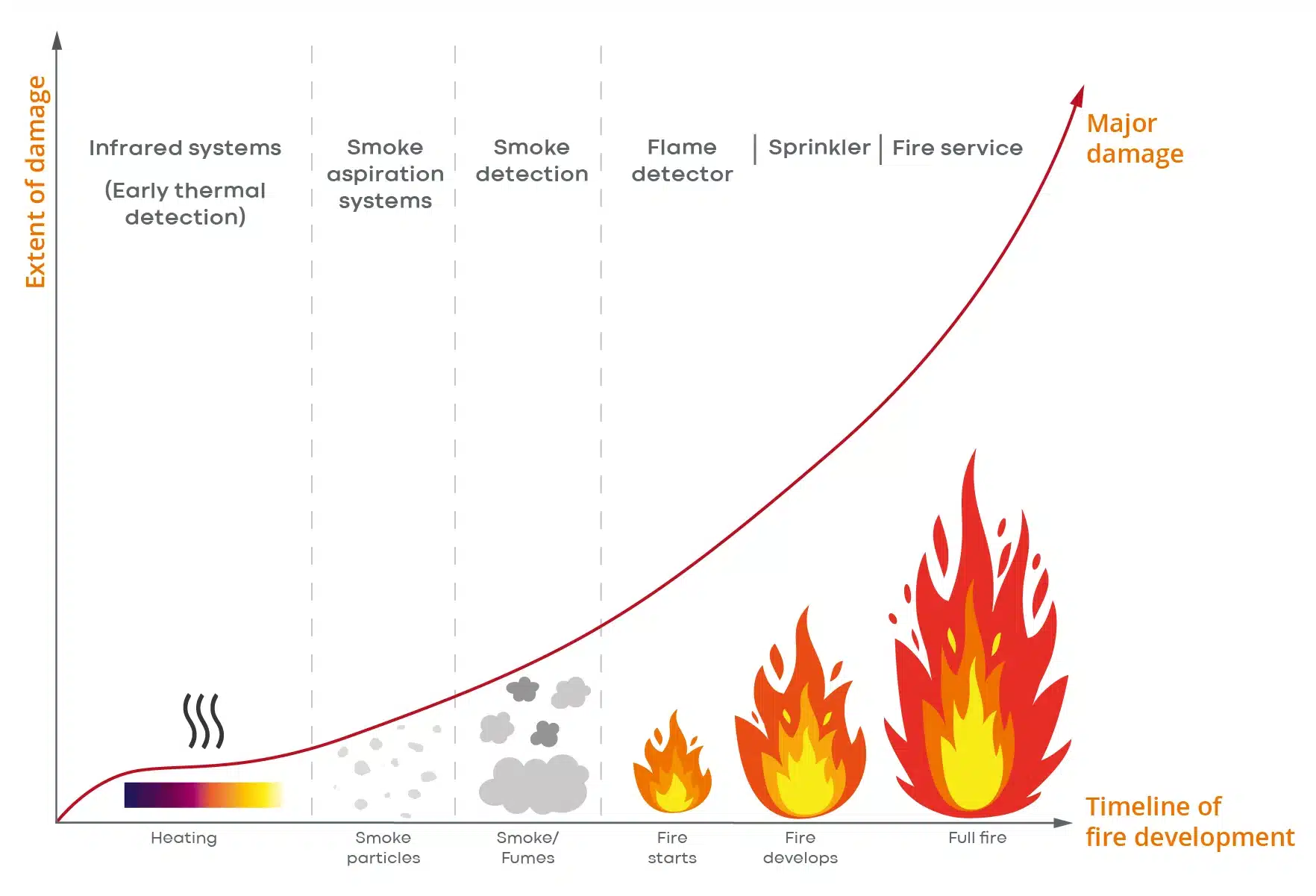

1. Early Fire Detection and Timely Alarms

- Heat Detectors: Many factory areas use heat detectors to find fires. This is common in places with big temperature swings or much smoke and dust, which can make smoke detectors less effective. These detectors must operate at precise temperature thresholds. This ensures they trigger alarms when temperatures rise abnormally. Such timely alerts prevent fires from spreading. Faulty calibration equipment can lead to inaccurate heat sensors, delaying or preventing alarms.

- Overheat Monitoring Systems: Overheating equipment (like machine bearings, motors, or transformers) often causes fires. Temperature monitoring systems need accurate measurements for early warnings. This allows quick intervention before flames ignite.

2. Safe Process Control

- Preventing Overheating and Chain Reactions: Many chemical, energy, or metallurgical processes need temperatures kept within a very narrow range. Inaccurate temperature measurement devices mean temperatures could exceed safe limits. This might cause uncontrolled chemical reactions, explosions, or melting materials.

- Controlling Cooling/Heating Systems: These systems depend on precise temperature data. They adjust valves, pumps, or heaters based on this data. Inaccuracies can cause a loss of temperature control. This directly creates a fire risk.

3. Ensuring the Effectiveness of Automatic Fire Suppression Systems

- In large factories, sprinkler systems (automatic water sprinklers) or gas/foam fire suppression systems often activate based on temperature sensor data. Many sprinkler heads have independent thermal glass bulb activation. However, larger systems might integrate sensors with a central control panel. This integration activates fire pumps, opens valves, or controls flow rates. Sensor accuracy, ensured by periodic calibration, becomes key here. It drives the rapid response of fire suppression systems.

Thermocouple Simulator Calibration: The Decisive Safety Link

Here’s the crucial point: Our temperature measurement devices must be reliable. Therefore, the tools we use to test them also need rigorous testing and calibration. Thermocouple simulator calibration ensures the accuracy of the “standard.” We use this standard to verify temperature sensors and control devices within the fire protection system.

1. Ensuring the Reliability of Testing Equipment

A thermocouple simulator generates standard voltage signals. It precisely mimics a thermocouple’s behavior at different temperatures. If the simulator itself is inaccurate (due to aging, impact, or environment), it will produce wrong mV signals. Consequently, any temperature measurement device calibrated using this faulty simulator will also show errors. This creates a “chain of errors” that spreads throughout the plant’s measurement system. Calibrating the simulator ensures its mV outputs are accurate against national or international standards (NIST-traceable). Thus, it guarantees the accuracy of the devices tested by it.

2. Verifying Safety and Alarm Thresholds

In fire protection, activating alarms or suppression systems at precise temperature thresholds is paramount.

If a fire alarm panel or PLC activates at 60°C, it must correctly recognize 60°C. A calibrated simulator lets technicians precisely test the control device’s response. They test at critical temperature points (like alarm or suppression activation points). This ensures the system will function correctly when the actual temperature reaches that threshold.

3. Preventing Overheating and Explosion Risks

Many high-temperature industrial processes carry potential fire and explosion risks. These risks arise if temperatures exceed safety limits. Thermocouple sensors and controllers must work together to keep temperatures safe. If a reading device is inaccurate (e.g., it reads lower than the actual temperature), the controller might not activate cooling or shutdown measures promptly. This can lead to overheating, creating a fire or explosion risk. Thermocouple simulator calibration indirectly ensures that these controllers operate with accurate temperature data. This, in turn, helps maintain operational safety.

4. Supporting Fast and Effective Troubleshooting

When a temperature measurement system issue arises (like a faulty sensor reading or an incorrect value), quick diagnosis is essential. This avoids production interruptions and safety risks. A calibrated thermocouple simulator is an invaluable tool for isolating faults. Technicians can substitute the actual thermocouple’s signal with a standard signal from the simulator. If the reading device works correctly with the simulated signal, the problem lies with the thermocouple or its wiring. Conversely, if the device still reads incorrectly, the problem is with the reading device itself. This rapid diagnostic ability significantly reduces downtime. It also ensures quick restoration of the FP system.

5. Compliance with Legal and Industrial Safety Standards

Hazardous industries (like oil and gas, chemical, and power) follow strict national and international safety standards (e.g., ISO, NFPA, API). These standards mandate periodic calibration for all critical measurement devices. They also require traceable calibration records. Thermocouple simulator calibration is an essential part of this. It provides documented proof that the tools maintaining fire protection safety standards are compliant. This is not only legally important; it also builds confidence in the plant’s safety system.

Consequences of Neglecting Simulator Calibration

Neglecting thermocouple simulator calibration can lead to severe consequences. These include:

- Accumulated Errors: An inaccurate simulator means every subsequent calibration of other temperature measurement devices will be flawed. These errors build up over time, resulting in unreliable temperature data.

- Fire and Accident Risk: Inaccurate temperature data can cause systems to fail. They might miss detecting overheating, or fail to activate alarms or preventive measures in time. This can lead to fires, property damage, and even casualties.

- Product Loss and Quality Degradation: Inaccurate temperatures directly affect product quality in many processes. This causes waste and economic losses.

- Fines and Reputation Damage: Failing to comply with safety regulations can result in large fines and operational shutdowns. It can also severely harm a company’s reputation.

Practical Recommendations

To ensure maximum fire protection safety in complex industrial environments, businesses should:

- Perform Regular Calibration: Schedule periodic calibration for all thermocouple simulators. Use competent and accredited laboratories or entities. This ensures measurement traceability.

- Use High-Quality Equipment: Invest in thermocouple simulators and calibration equipment from reliable manufacturers.

- Train Personnel: Ensure technicians have strong knowledge of calibration procedures. They must understand its importance for FP safety.

- Maintain Detailed Records: Keep complete and updated calibration records for all equipment, including simulators.

Conclusion

Thermocouple simulator calibration might seem like a small technical task. However, it is an indispensable and highly critical link in the chain of activities ensuring fire protection safety. This is especially true in complex industrial environments. By guaranteeing the accuracy of the very tools used to test temperature sensors, we build a strong foundation. This foundation supports early fire detection, safe process control, and maximum protection for personnel and assets. Investing in high-quality calibration means investing in a safer, more stable future for your business.