Torque screwdriver calibration is one of the most important steps in ensuring product quality, equipment safety, and process reliability. Whether you are a technician tightening fasteners daily, a QA manager preparing for an audit, or a beginner just getting familiar with torque tools, understanding how calibration works can prevent a long list of costly problems.

This guide walks you through everything you need to know: why calibration matters, how drift happens, how often you should calibrate, practical checklists, standards, and how to choose a trusted calibration service.

Throughout the article, we will also highlight how Techmaster supports businesses with reliable torque tool calibration and verification services.

1. What Is Torque Screwdriver Calibration and Why It Matters

A torque screwdriver is a handheld tool used to apply a specific torque to fasteners, commonly found in electronics assembly, automotive components, aerospace parts, medical devices, and general manufacturing.

Torque Screwdriver Calibration is the process of verifying and adjusting the tool to ensure it delivers torque within an acceptable accuracy range. Even the best tools naturally drift over time because of:

• mechanical wear

• spring fatigue

• repeated loading

• temperature and humidity changes

• accidental impacts or misuse

If drift is not detected early, the resulting errors can cause:

• overtightening (cracked parts, damaged threads)

• undertightening (loose fasteners, safety failures)

• increased scrap & rework

• failed audits or customer complaints

Across all industries, torque accuracy is a silent guardian of product quality. And calibration is the key to maintaining it.

2. Types of Torque Screwdrivers and Their Calibration Needs

Not all torque screwdrivers behave the same, and understanding your tool type helps determine the correct calibration method and frequency.

Mechanical Torque Screwdrivers

These use a mechanical clutch or spring. They drift primarily due to spring wear. Calibration focus: checking deviation at multiple load points.

Preset Torque Screwdrivers

Pre-adjusted to one torque value. Often used in mass production. Calibration ensures the preset torque stays within tolerance.

Digital Torque Screwdrivers

Include sensors, chips, and digital displays. Calibration is more sensitive and may require ISO 17025 labs for high accuracy.

Electric & Pneumatic Torque Tools

Used in high-volume assembly lines. Require both torque calibration and performance verification under load.

Each type has different tolerance levels and calibration intervals. The more complex the tool, the more you should rely on certified labs.

Is Your Torque Screwdriver Lying to You?

Calibration isn’t just a certificate; it’s the heartbeat of quality control. Ensure safety, compliance, and precision in every turn.

The Cost of “Good Enough”

Many manufacturers overlook torque tools until a failure occurs. However, data shows that improper fastening is a leading cause of assembly line failures. Under-tightening leads to loose parts; over-tightening causes stripped threads and stress fractures.

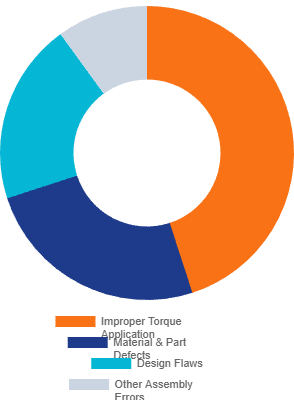

Primary Causes of Assembly Failures

Source: Industry Analysis 2024. Torque issues outweigh material defects.

Safety Liability

In the US market, a single safety incident due to a loose screw can result in millions in litigation costs.

Production Downtime

Detecting a torque error late often means stopping the line and quarantining batches for re-inspection.

Compliance Assurance

ISO 9001 audits require documented evidence of tool calibration traceability to NIST standards.

3. In-House vs Professional Lab Calibration

There are two primary pathways for torque screwdriver calibration.

In-House Calibration

Suitable for manufacturers with basic torque testers and trained staff.

Advantages:

• Faster turnaround

• Saves cost

• Useful for daily or weekly verification

Limitations:

• May not produce traceable results

• Equipment must be maintained and certified

• Not acceptable for strict audits (ISO, aerospace, medical)

Professional Lab Calibration

Essential when you require traceable, documented, and certified accuracy.

Advantages:

• Precision instruments

• Traceability to NIST or equivalent

• Detailed calibration certificates

• Suitable for ISO/IEC 17025 requirements

Techmaster provides ISO/IEC 17025 certified calibration services, ensuring torque tools meet international standards, with full traceability and professional reporting.

Daily Verification (Quick Check)

Technicians should perform a daily quick check to detect significant drift early:

• Test the preset torque

• Compare readings on a small torque analyzer

• Mark pass/fail before starting the shift

Daily verification is not a replacement for calibration, but it minimizes risk during production.

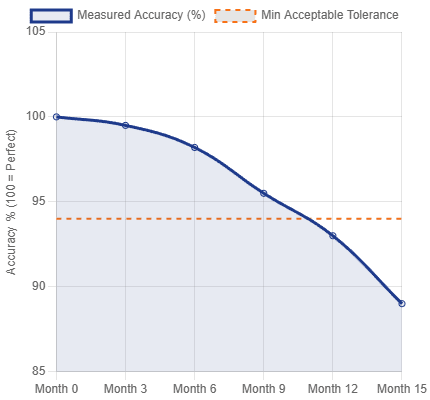

The “Drift” Phenomenon

Mechanical springs inside torque screwdrivers fatigue over time. Without adjustment, a tool set to 5 Nm might actually deliver 4.5 Nm or 5.5 Nm after months of use.

Key Insight:

Most tools drift “out of tolerance” (OOT) between months 9 and 12 of heavy usage.

Tool Accuracy Degradation Over Time

The ISO 6789 Calibration Workflow

Calibration isn’t just turning a knob. It is a rigorous scientific process. Here is the lifecycle of your tool in our lab.

1. ‘As Found’ Test

We test the tool exactly as it arrived to determine if past work is suspect.

2. Adjustment

Internal springs are adjusted, cleaned, and lubricated to restore range.

3. ‘As Left’ Test

Final verification against NIST-traceable transducers to ensure ±6% accuracy.

4. Certification

Issue of calibration certificate with full data traceability.

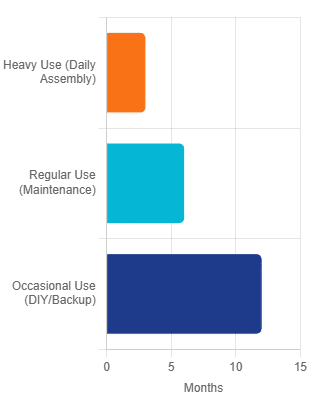

When to Calibrate?

One size does not fit all. Frequency depends on how often the tool is used.

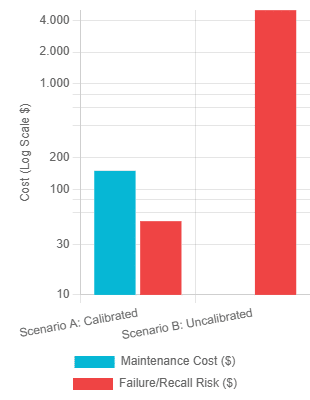

The ROI Calculation

Comparing the trivial cost of annual calibration vs. the catastrophic cost of a product recall.

4. Understanding Accuracy, Tolerance, and Standards

Calibration is not only about hitting the correct torque value. It’s about meeting recognized accuracy and traceability requirements.

Key Concepts

• Accuracy: How close the applied torque is to the target.

• Tolerance: Allowable deviation (e.g., ±6%).

• Deviation: Difference between actual and expected value.

• Repeatability: Ability to produce consistent torque multiple times.

Important Standards

• ISO 6789: International standard for hand torque tools.

• ISO/IEC 17025: Standard for testing and calibration labs.

• NIST Traceability: Ensures calibration results are linked to a national measurement standard.

How to Read a Calibration Certificate

A proper certificate should include:

✓ Tool info

✓ Serial number

✓ Range tested

✓ Measurement results

✓ Uncertainty

✓ Traceability

✓ Technician signature

✓ Lab accreditation details

Techmaster issues fully traceable calibration certificates that satisfy audits for automotive, electronics, and medical device clients.

5. Maintenance and Storage Best Practices

A calibrated torque screwdriver will only stay accurate if properly maintained. Best practices include:

• Bring tool back to zero when not in use

• Avoid exceeding maximum torque

• Do not lubricate internal clutch unless specified

• Store away from humidity and vibration

• Avoid dropping or impact

• Keep a calibration logbook for each tool

Regular care significantly extends tool life and reduces calibration cost.

6. How to Choose the Right Torque Screwdriver and Calibration Service

Choosing the Right Tool

• Identify the torque range required

• Check accuracy class

• Choose mechanical or digital based on assembly type

• Consider preset models for repetitive production

• Review build quality and warranty

Choosing a Calibration Partner

A reliable calibration service should provide:

• ISO/IEC 17025 accreditation

• Traceable calibration standards

• Detailed certificates with uncertainties

• Reasonable turnaround time

• Technical support if tool fails calibration

• On-site service options (if needed)

Techmaster offers all the above, plus:

• Large range of torque equipment handling

• Fast turnaround

• Professional consultation for QA and production teams

• On-site calibration programs for factories in Vietnam

7. Summary and Key Recommendations

Torque screwdriver calibration is essential for maintaining product quality, safety, and compliance. Regardless of your application, a calibrated torque screwdriver ensures each fastener is tightened to the correct specification.

To keep your torque tools reliable:

• Calibrate every 3–12 months depending on use

• Perform daily verification

• Follow proper storage and maintenance

• Choose accredited calibration services

• Maintain calibration history for audits

If you want consistent accuracy, lower rework costs, and smooth audits, building a long-term calibration program is the most effective approach.

Techmaster is ready to support your business with certified torque calibration, repair, and tool management programs tailored for manufacturing environments.

PrecisionTorque Labs

A reliable partner for ISO 17025 Torque Screwdriver Calibration services.