Accurate internal diameter measurements can make or break a product’s performance. Yet many labs neglect one small but critical device: the inside micrometer. Inside micrometer calibration isn’t just a checkbox for compliance; it’s a strategic move to prevent cascading quality failures. Whether you’re a seasoned technician, a QA manager, or just beginning to explore dimensional metrology, understanding the impact of calibration is essential.

1. Understanding Inside Micrometers and Their Industry Role

What Is an Inside Micrometer?

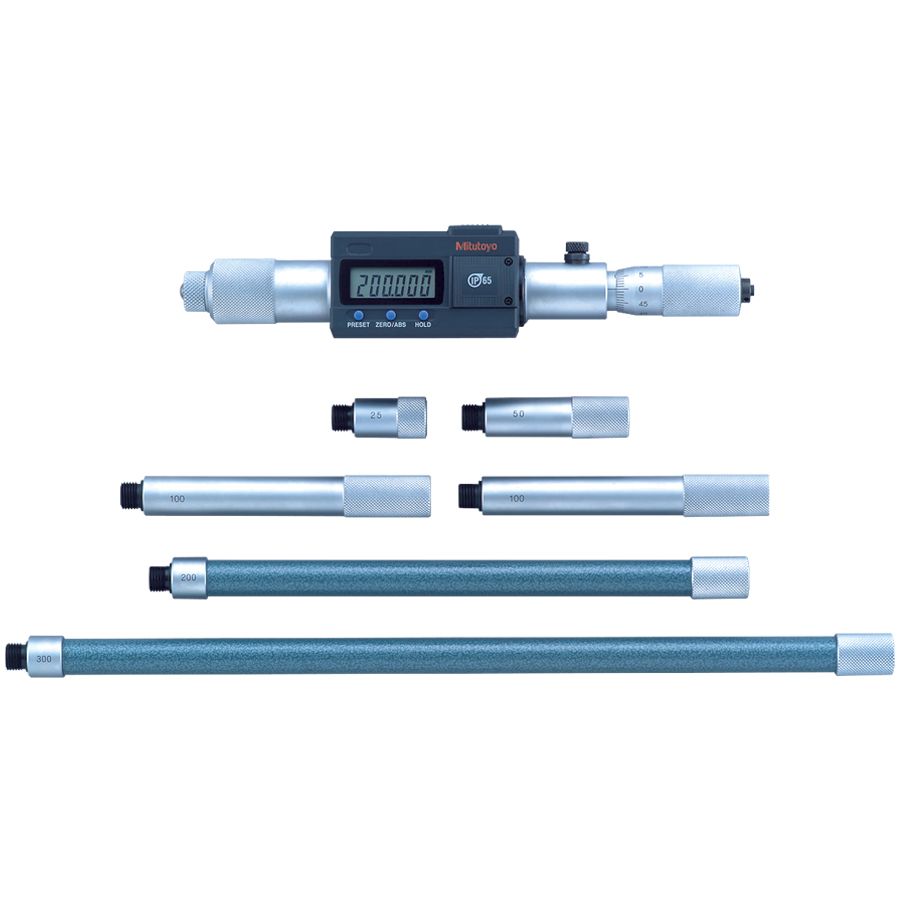

An inside micrometer measures the internal dimensions of objects such as bores, pipes, and cavities. Unlike external micrometers, these tools reach within a part to gauge its internal consistency with high accuracy. It’s not just about measuring a hole; it’s about ensuring that hole supports pressure, alignment, and performance in the larger assembly.

Types of Inside Micrometers

- Rod Type: Ideal for larger diameters and deep bores, often used in heavy manufacturing or aerospace applications.

- Tubular Type: Lightweight and versatile, these are ideal for less demanding measurements where portability is key.

- Caliper Type: Common in general manufacturing, good for quick checks on the floor.

Each type comes with its strengths, and choosing the right one depends on your application. But regardless of type, all share one thing in common: they must be calibrated regularly to ensure their readings remain trustworthy.

Industries That Rely on Inside Micrometers

- Aerospace & Defense: Ensuring turbine bore tolerances where even a micron of error can affect thrust or safety.

- Automotive: Measuring engine cylinders, brake system housings, and transmission components.

- Medical Devices: Verifying precision tolerances in implants, surgical instruments, and diagnostic equipment.

- Pharmaceutical Equipment: Monitoring internal wear in stainless steel mixing tanks or clean-room-compatible components.

The Real Cost of Neglect

Overlooking inside micrometer calibration can result in:

- Inaccurate assemblies that lead to part rejections or product recalls.

- Regulatory penalties if audit trails are incomplete or non-compliant.

- Undetected process drifts that ripple through production.

- Misleading measurement data that affects other tools relying on these measurements as reference points.

If you’re managing a production line or a QA lab, you can’t afford the assumption that “it’s probably still accurate.” Calibration verifies that assumption—or challenges it before it costs you.

2. Why Regular Calibration Matters

Inside micrometers are precision tools. But even precision wears with time. Daily use, accidental knocks, dust exposure, and temperature shifts all take a toll. Like any tool, performance degrades—not dramatically, but subtly enough to cause significant issues downstream.

Let’s break it down:

- Wear and Tear: Threads and contact points lose their tightness over time.

- Storage Conditions: Humidity and temperature fluctuations may cause expansion, corrosion, or drift.

- User Variability: Different operators might use varying pressure or technique, increasing uncertainty.

Skipping calibration means:

- You’re flying blind—the number you read might not be the number that’s real.

- You can’t defend your data in audits or root cause investigations.

- You risk production downtime when a defect traced to a bad micrometer suddenly shuts the line.

Calibration of inside micrometers ensures traceability—a metrological breadcrumb trail all the way back to national standards like NIST. That’s not just for show. It’s what ensures your measurement has credibility, whether in court, in a client presentation, or during a surprise ISO audit.

3. The Calibration Process – Simplified

Calibration sounds intimidating, but it’s a systematic and manageable process when performed by a qualified lab. Here’s what happens:

- Visual Inspection: The tool is checked for cracks, dirt, or deformation. Even small dents can introduce massive error.

- Zero Setting: The micrometer is verified to return to zero when fully closed or compared to a reference standard.

- Comparative Measurement: The micrometer is tested against certified gauge blocks or master ring gauges, depending on its type.

- Adjustment or Reporting: If deviations are within permissible limits, they are recorded. If not, adjustments are made or repair is recommended.

- Certification: Results are documented, including environmental conditions, uncertainty values (if ISO 17025), and technician sign-off.

Want to see what a real calibration report looks like? Contact us to request a sample certificate.

4. In-House vs. Professional Calibration Services

Some organizations consider calibrating inside micrometers in-house. It seems faster. It seems cheaper. But there’s more beneath the surface.

| Factor | In-House Calibration | Professional Calibration |

|---|---|---|

| Upfront Cost | Lower | Higher, but value-packed |

| Long-Term Risk | High (missed errors) | Low (traceable, validated) |

| Expertise | Staff-dependent | Dimensional metrology experts |

| Standards | May lack traceability | ISO 17025 & ANSI/NCSL Z540.1 |

| Uncertainty Reporting | Rarely included | Fully documented |

| Audit Readiness | Often lacking | Fully compliant |

Let’s be real—in-house might save a few dollars today, but it can cost far more in:

- Rejected batches from customers

- Failed audits that stop production

- Lost contracts due to insufficient quality documentation

The ROI of professional calibration isn’t abstract—it’s measurable in smoother audits, fewer reworks, and higher customer satisfaction.

5. How to Choose a Calibration Service Provider

Choosing a calibration provider is like choosing a surgeon: credentials, precision, and trust matter.

Key Factors

- ISO 17025 Accreditation: This proves the lab’s competence is validated by a third party. Look for an ILAC MRA logo.

- Experience: Have they worked with your micrometer’s brand and model? Can they handle both legacy and modern tools?

- Reporting Depth: Do they just check a box, or do they provide measurement data, test points, and uncertainty values?

Technology & Innovation

- Automated Comparators: Reduce human error and increase repeatability

- Controlled Lab Conditions: Ensure temperature and humidity don’t skew results

- Paperless Systems: Digital access to certificates, reminders, and service logs

Practical Considerations

- Turnaround Time: How quickly do they return your tools?

- Pickup/Delivery Services: Does the provider handle logistics?

- Online Access: Can you view certificates 24/7 via portal?

Tip: Techmaster Electronics checks all these boxes and more.

6. How Often Should I Calibrate My Inside Micrometer?

Calibration intervals depend on usage, environment, and criticality. But here are solid guidelines:

- Every 6–12 months for routine use

- Every 3–6 months for shop-floor or harsh environments (e.g., high humidity, dust exposure)

- Immediately after shock, impact, or suspected damage

- Before using the tool in final product inspection or regulatory reporting

Think of calibration like preventive maintenance. It might seem optional—until something breaks, and then it’s suddenly urgent. Regular calibration is your insurance policy against bad data.

If your company’s quality management system is ISO-certified, syncing calibration intervals with audit cycles is a smart way to stay compliant and avoid last-minute scrambling.

7. Why Techmaster Electronics?

When you choose Techmaster Electronics, you’re not just picking a service provider—you’re gaining a metrology partner.

Deep Expertise

With 30+ years of experience in calibration and dimensional metrology, Techmaster services industries from high-precision aerospace assemblies to ultra-sterile pharmaceutical equipment.

Multi-Tiered Service Levels

- Commercial Calibration: NIST traceable, for general industrial use

- ANSI/NCSL Z540.1 Calibration: Includes test data, ideal for aerospace/defense

- ISO 17025 Accredited Calibration: Full uncertainty reporting, internationally recognized and audit-ready

Benefits You Can Expect

- Local Pickup & Delivery: No more packaging and shipping hassles

- Fast Turnaround Times: Get your tools back with minimal downtime

- On-Site Service Available: We come to you, minimizing production disruption

- Online Certificate Portal: 24/7 access to records, download reports anytime

Techmaster’s customer-first model isn’t just marketing—it’s baked into every interaction. From personalized advice to traceable documentation, you get peace of mind that’s worth every penny.

8. FAQ: Inside Micrometer Calibration

Q1: Can I use my micrometer if it’s slightly out of spec?

A: Not recommended. Even minor deviations can result in failed inspections, non-conformance reports, and rework.

Q2: What standards should my calibration meet?

A: ISO/IEC 17025 is the gold standard. At a minimum, ensure NIST traceability for internal compliance.

Q3: Is professional calibration worth it for low-use tools?

A: Yes—especially if those tools are used for final QA, regulatory submissions, or critical assemblies.

Q4: How long does inside micrometer calibration take?

A: At Techmaster, turnaround is typically 3–5 business days, with expedited options available for urgent needs.

9. Conclusion

Inside micrometer calibration is not optional—it’s foundational. Whether you’re trying to meet ISO standards, pass customer audits, or simply sleep better at night knowing your measurements are accurate, investing in professional calibration is the smart move.

With Techmaster Electronics, you don’t just get a service—you get peace of mind backed by decades of expertise, accredited labs, and results you can trace, trust, and act on.

Call Techmaster Electronics today or email us to speak with a dimensional calibration expert.