Controlling particle contamination in cleanrooms, labs and hydraulic systems is essential. Furthermore, regularly calibrating particle monitors—including inline and online counters—keeps these devices accurate. If you neglect calibration, sensors drift and cause false alarms, missed contamination and off‑spec products. Consequently, this article introduces the basics of particle monitoring, explains why calibration matters, suggests how often to do it and shows why partnering with a certified service provider such as Techmaster helps. In particular, engineers, quality managers and procurement officers will find practical insights here.

Understanding particle monitors and counters

To begin with, there are two main types of devices that measure particles: optical particle counters and nephelometers. Specifically, optical particle counters count and size each particle, while nephelometers look at the overall light scattering from a group of particles and output a Particle Index that relates to mass. However, people often call nephelometers “particle monitors,” but they cannot tell particle sizes apart or count each one. As a result, they are good for tracking contamination trends, not detailed analysis. Therefore, when manufacturers call certain devices “inline particle monitors,” they usually mean inline optical particle counters that take continuous readings.

Types of particle‑monitoring equipment

In addition, particle‑monitoring devices come in different types, and knowing which type you have helps you follow the right calibration rules.

-

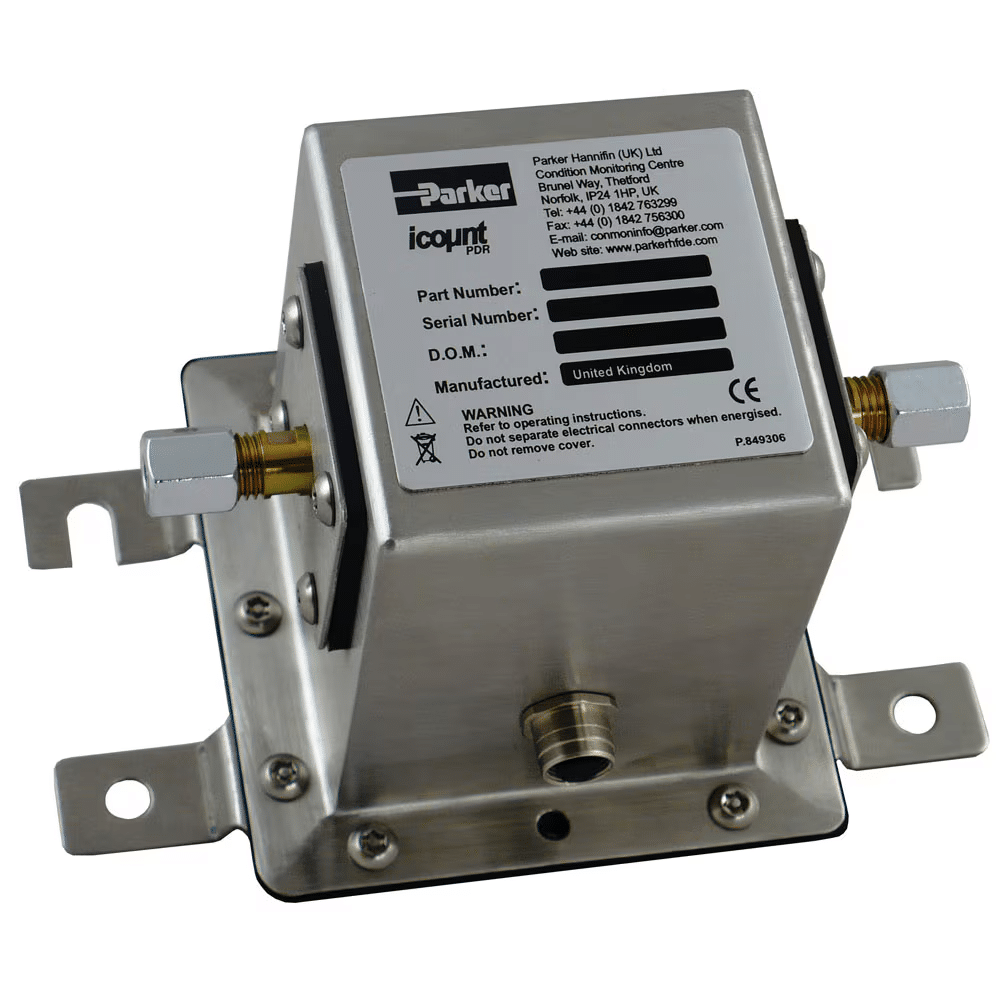

Inline particle monitors. For example, operators install these monitors directly in process lines or hydraulic circuits. They take continuous readings without manual sampling; this means they are valuable in automated production or oil condition monitoring. For instance, Parker’s iCountPD series (like the IPD32223130) is a common example. Moreover, these devices use laser‑based optical sensors to count particles and send data through analog or digital outputs.

-

Online particle counters collect samples from a process stream and return measurements in near real time. They are common in fuel and lubricant systems and often interface with data acquisition systems.

-

Portable or handheld particle counters are used to certify cleanrooms, monitor HVAC filters or perform spot checks. They are convenient but require careful handling and regular calibration because they are prone to mechanical shock.

Regardless of the form factor, all optical particle counters work by passing particles through a laser beam and measuring the scattering of light. Variations in light intensity correspond to different particle sizes. Because the laser and optics can drift over time, calibration is essential for maintaining accuracy.

Spotlight: Parker iCountPD IPD32223130

To ground the discussion, consider Parker’s iCountPD IPD32223130 – an inline particle monitor used in aviation fuel and hydraulic systems. It features a solid‑state laser sensor, integrated RS‑232 communications and outputs contamination codes in accordance with ISO 4406 cleanliness classes. The device has a ±1 ISO code accuracy and is designed for high‑pressure operation. Manufacturer guidance recommends recalibrating annually or sooner if used in harsh conditions. This example illustrates how a specific Parker iCountPD calibration fits into the broader context of particle monitor calibration.

Why Calibration Is Critical

Unlike many sensors, particle counters measure extremely small signals. Their optical systems can drift due to laser ageing, contamination on lenses or sensor degradation. When uncalibrated, readings may under‑report contamination (leading to undetected risk) or over‑report it (triggering unnecessary shutdowns). Calibration compares a monitor’s output against a traceable standard and adjusts it to ensure both particle sizing and counting accuracy. Several drivers make calibration non‑negotiable:

-

Regulatory compliance. Cleanrooms operate under ISO 14644 and GMP regulations that mandate regular particle counter calibration. For example, ISO 21501‑4 defines performance and calibration procedures for airborne particle counters. Calibration certificates are required for ISO 14644 compliance.

-

Quality assurance. Manufacturers and laboratories depend on accurate particle data to validate product quality and prevent contamination. Inaccurate instruments can result in rework, product recalls or regulatory sanctions.

-

Process reliability. In hydraulic and lubricant systems, excessive particles accelerate component wear. Inline particle monitor calibration ensures that maintenance is based on reliable contamination data and helps avoid catastrophic failures. ISO 11171 specifically addresses calibration of liquid particle counters and defines procedures for particle‑sizing calibration, flow rate testing and sensor resolution.

-

Cost optimisation. Precise calibration intervals avoid both under‑servicing and over‑servicing. Aligning calibration frequency with usage environment reduces downtime and maximises the instrument’s life.

Accredited calibration laboratories such as Techmaster are required to perform calibrations against national standards. Techmaster’s services emphasise ISO/IEC 17025 accreditation and ANSI/NCSL Z540.1 compliance, ensuring traceability to national metrology institutes.

Standards and Guidelines

Calibration of particle monitors is governed by several standards:

-

ISO 11171 – Calibration of automatic particle counters for liquids. This standard sets out procedures for sample preparation and sensor calibration for liquid particle counters. It specifies use of NIST Standard Reference Materials and covers particle sizing, coincidence error, resolution and flow‑rate checks.

-

ISO 21501‑4 – Light scattering airborne particle counters. Defines calibration and verification methods for optical particle counters used in cleanrooms. It requires calibration against an aerosol electrometer and provides guidelines for particle sizing and counting efficiency.

-

ISO 14644 – Cleanrooms and associated controlled environments. Describes classification of air cleanliness by particle concentration and stipulates that instruments used for certification must be calibrated.

-

ANSI/NCSL Z540.1 and ISO/IEC 17025 – General standards for calibration laboratories. Techmaster emphasises compliance with both, ensuring that calibrations meet international quality and competence requirements.

These standards provide the framework for establishing measurement traceability, defining uncertainty budgets and documenting calibration results. A properly calibrated particle monitor should include a certificate with traceability to national standards (such as NIST) and a statement of measurement uncertainty.

How Often Should You Calibrate?

Calibration intervals depend on the operating environment, regulatory context and manufacturer recommendations. Industry practice generally follows these guidelines:

-

High‑risk environments (pharmaceutical or ISO Class 5 cleanrooms). Because sterility and contamination control are critical, particle counters should be calibrated every six months. Some facilities even recalibrate quarterly if instruments are used continuously.

-

General manufacturing. For less sensitive production and laboratory environments, annual calibration (every 12 months) is typically sufficient. This frequency balances cost and reliability.

-

Hydraulic and lubricant systems. Inline monitors like the Parker iCountPD operate under harsh conditions; manufacturers often recommend a 12‑month recalibration or sooner if contamination levels fluctuate widely.

-

Portable instruments in cleanrooms. Handheld counters subjected to rough handling may require more frequent checks. Users should monitor drift or unusual readings and shorten the interval if necessary.

| Pharmaceutical |

6 mo |

| Cleanroom ISO Class 5 |

6 mo |

| General Manufacturing |

12 mo |

| Other Industrial |

12 mo |

Signs that recalibration is needed

Even when a schedule is in place, certain indicators suggest an earlier calibration is warranted:

-

Unexpectedly high or fluctuating readings. If contamination measurements vary significantly without a clear cause, calibration drift may be to blame.

-

After repairs or replacement. Any time a particle monitor is serviced, repaired or components (such as lasers or pumps) are replaced, recalibration is essential.

-

Regulatory audits or certification deadlines. Prior to facility audits or cleanroom recertification, verify that instruments carry current calibration certificates.

-

Harsh operating conditions. Extreme temperatures, vibration or high contamination loads may accelerate sensor degradation. Consider shortening the interval under such circumstances.

Calibration Workflow and Best Practices

A robust calibration process includes several stages designed to ensure accuracy and traceability:

-

Pre‑calibration inspection. The instrument is examined for physical damage, cleanliness and proper operation. Accessories (such as zero‑count filters or sample tubing) are checked and replaced if necessary.

-

Reference comparison. The particle counter’s sizing and counting functions are compared against a higher‑accuracy reference. For liquid particle counters, ISO 11171 calls for using NIST SRM 2806 suspension as a primary calibration medium. For airborne counters, an aerosol electrometer serves as the reference.

-

Adjustment and verification. If deviations exceed acceptable limits, internal adjustments or firmware corrections are applied. The instrument is then re‑tested to confirm compliance.

-

Certification and documentation. Accredited labs provide a certificate detailing measurement results, uncertainty estimates and traceability chains. Maintaining these records is essential for audits.

-

Post‑calibration support. Some service providers offer reminder systems, instrument loans during calibration and environmental testing to complement calibration results.

Working with an accredited provider ensures adherence to these steps and reduces the risk of calibration errors. Poorly executed calibration may be worse than no calibration at all.

Selecting a Calibration Partner: Techmaster’s Approach

Techmaster Electronics has served the calibration market for more than 30 years. Their comprehensive approach goes beyond simple calibration to encompass repair, sales and rental services. Clients benefit from a single partner who can manage the entire lifecycle of particle monitoring equipment. Key differentiators include:

-

Accreditation and standards compliance. Techmaster is accredited to ISO/IEC 17025 and meets ANSI/NCSL Z540.1. Calibration results are traceable to NIST or other national metrology institutes. This assures customers that measurements are defensible in audits and regulatory reviews.

-

Broad discipline coverage. Their capabilities span RF/microwave, electrical, mechanical, dimensional and cleanroom disciplines. For particle monitors, this means access to supporting calibration equipment such as air quality chambers and reference aerosol generators.

-

Lifecycle services. In addition to calibration, Techmaster offers repair services with evaluation fees, plus a sales and rental program that helps clients continue operations while their instruments are being serviced.

-

Experienced staff and short turnaround. With decades of experience, Techmaster’s technicians understand subtle issues like coincidence errors, flow‑rate calibration and sample preparation. Their focus on quick turnaround minimises downtime.

-

Customer focus. Techmaster emphasises communication and flexibility, tailoring calibration intervals and service plans to the client’s operational requirements. They also provide environmental testing for cleanrooms and can integrate results into holistic contamination control plans.

Case example: Calibrating a Parker iCountPD at Techmaster

When a client submits a Parker iCountPD IPD32223130 for calibration, Techmaster’s process begins with a functional check and cleaning. The unit’s laser sensor is compared against a reference counter using ISO 11171 procedures. Techmaster technicians verify sizing accuracy across the device’s measurement range and adjust calibration factors if necessary. Flow‑rate accuracy and RS‑232 communication outputs are checked to ensure the monitor reports correct ISO 4406 contamination codes. Upon completion, the client receives a calibration certificate with measurement data, uncertainty estimates and evidence of NIST traceability. For clients in regulated industries, Techmaster can schedule automatic reminders to ensure that recalibration occurs before certificates expire, protecting compliance and process integrity.

Why Accurate Data Matters to Stakeholders

Beyond that, precise particle data underpins critical decisions. For instance, engineers depend on consistent readings to diagnose machine health; quality managers require documented proof for regulators; and procurement officers must weigh the cost of equipment against operational risk. However, if instruments drift because they aren’t calibrated, every decision becomes less reliable. Thus, following industry standards, scheduling calibrations at appropriate intervals and choosing an accredited lab are crucial steps in safeguarding product quality, protecting compliance and controlling costs.

Conclusion and Call to Action

In short, calibration isn’t just a box to tick. It protects your process, ensures regulatory compliance and prevents unplanned downtime. Although Schroeder Industries notes that contamination sensors should be calibrated approximately every two years, sectors like pharmaceutical manufacturing often need more frequent checks. Accordingly, whether your facility requires twice-yearly calibrations or annual checks, a proactive calibration program will pay dividends.

Finally, if you operate a particle monitor, inline monitor or a Parker iCountPD device that is due for calibration, contact Techmaster today. With ISO/IEC 17025‑accredited laboratories, seasoned technicians and decades of experience, we provide reliable, traceable calibration services. Moreover, we offer flexible scheduling, rapid turnaround and comprehensive documentation to give you peace of mind. Visit our website or call our team to arrange a calibration plan tailored to your facility’s needs.